Vertical stirrer

A vertical stirring and agitator technology, applied in cheese substitutes, dairy products, applications, etc., can solve problems affecting equipment design and layout, inconsistent quality of finished products, coagulant heavier than cooked pulp, etc., to improve production efficiency and product quality Quality, the effect of ensuring hygienic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

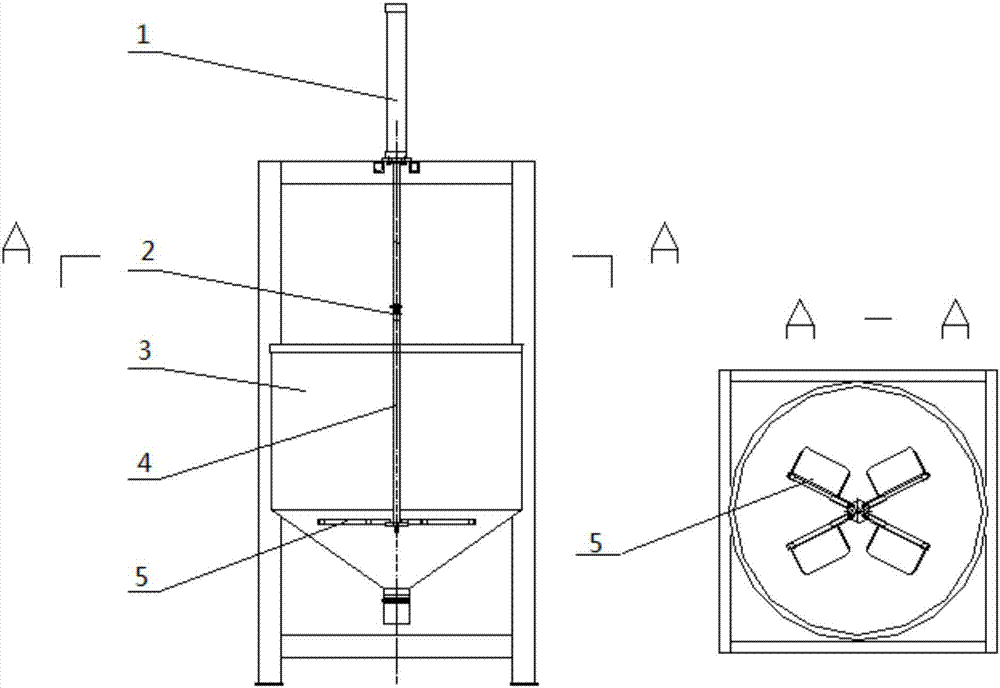

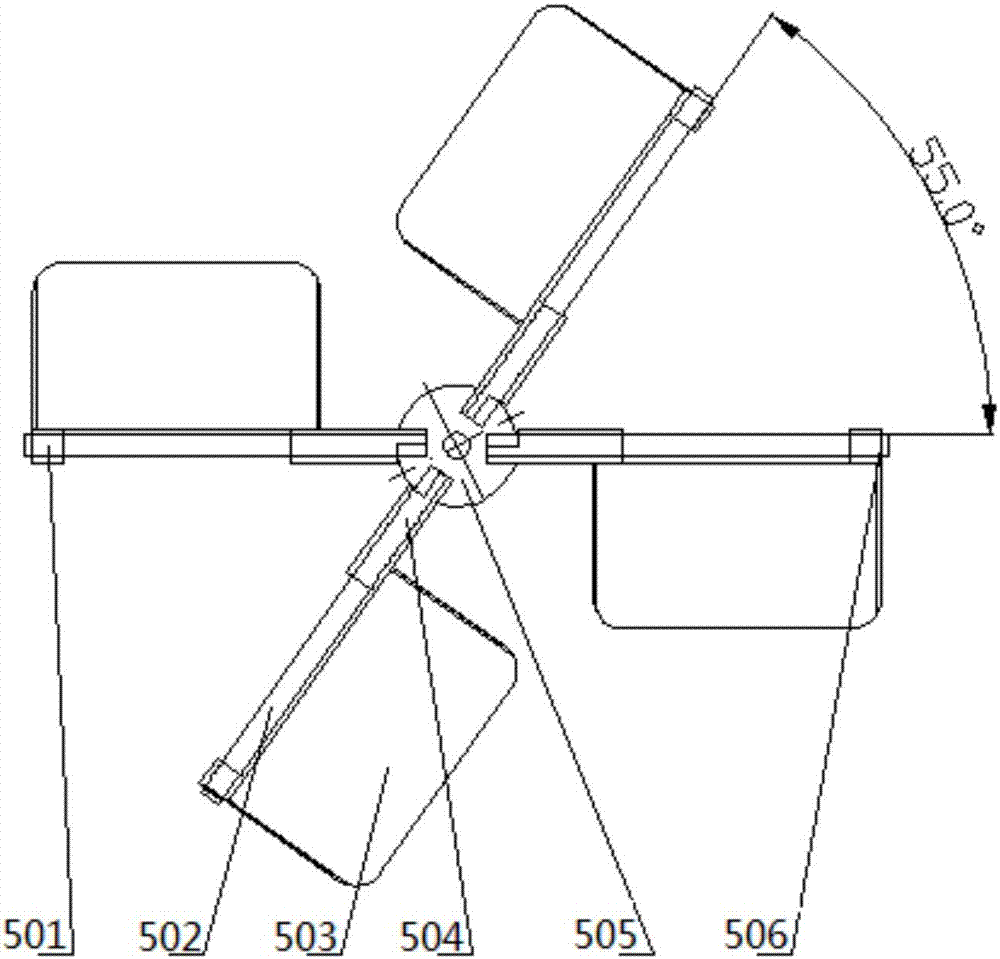

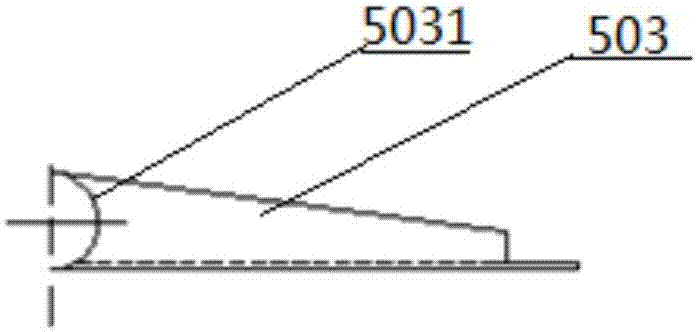

[0025] The invention provides a vertical agitator, comprising: a lifting cylinder, a pull rod, an agitator assembly and a mixing bucket; ring, the inner positioning sleeve is a tubular structure, and one end of the inner positioning sleeve is provided with a quarter-circumference arc baffle; the outer guide sleeve and the inner positioning sleeve are coaxially fixed on the paddle The two ends of the long side of the blade, the blade is sleeved on the rotation positioning shaft through the outer guide sleeve and the inner positioning sleeve, one end of the rotation positioning shaft is fixedly connected with the connecting plate, the The other end of the rotating positioning shaft is provided with a retaining ring to limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com