Enclosed pressure-limiting valve of pressure cooker and pressure cooker

A pressure limiting valve and pressure cooker technology, applied in pressure cookers, special materials for cooking utensils, cooking utensils, etc., can solve problems such as affecting user experience, continuous exhaust of pressure limiting valve, irregular swing, etc., to improve cooking quality and avoid abnormality Pressure relief, product stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

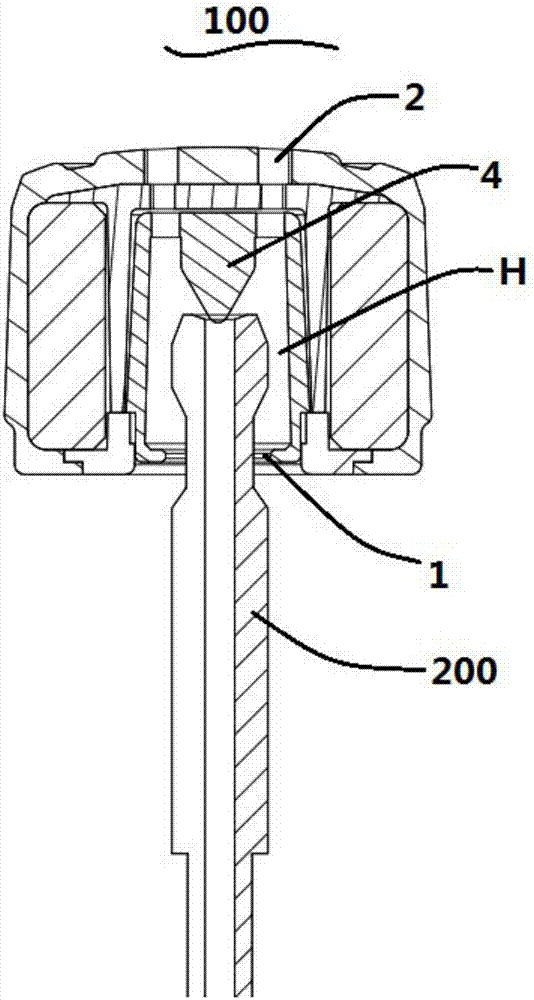

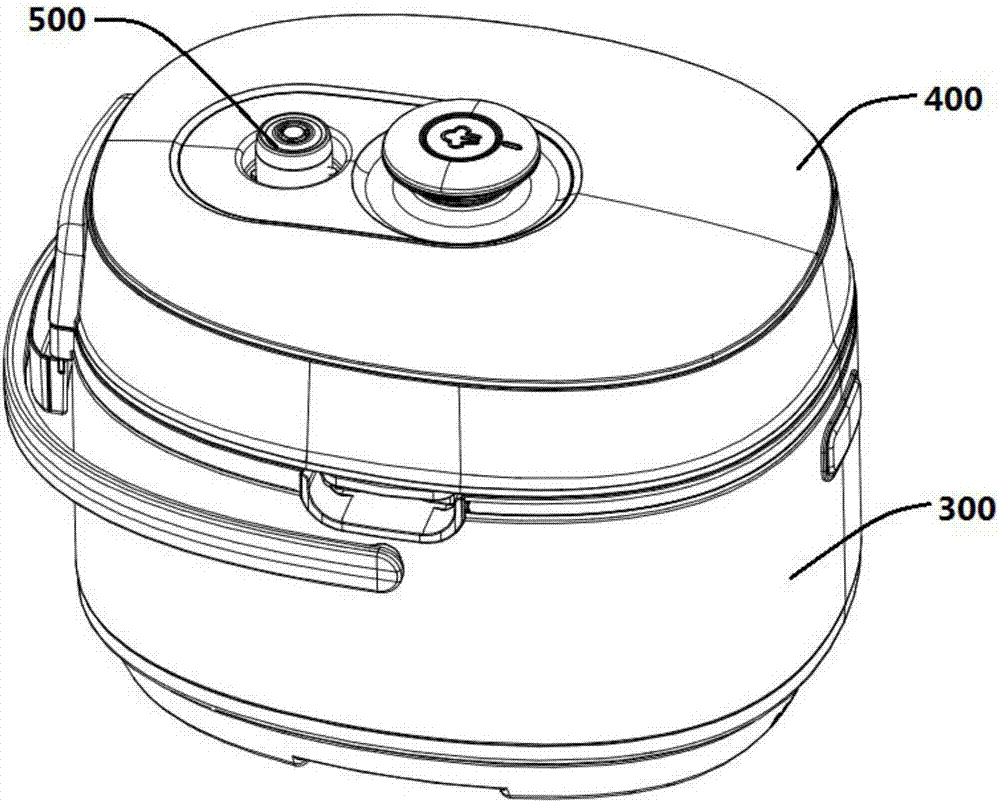

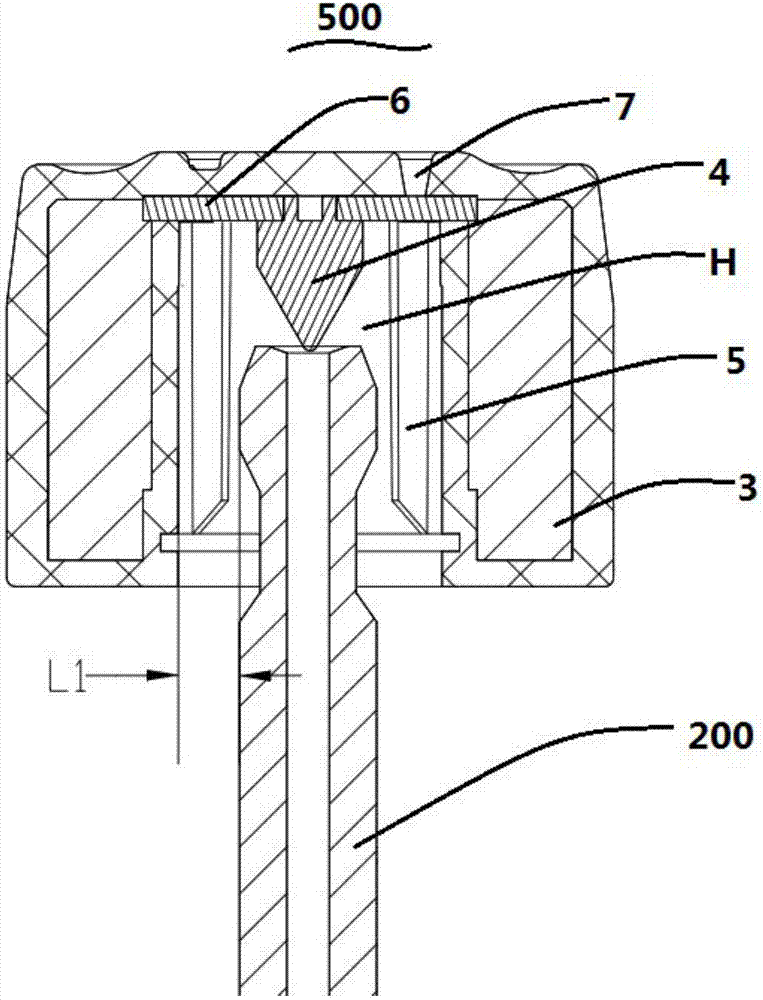

[0032] The present invention proposes a kind of pressure cooker, can refer to Figure 2-Figure 4 , comprising a pot body 300 and a pot cover 400, the pot cover 400 is provided with an exhaust pipe 200 and a pressure limiting valve installed in cooperation with the exhaust pipe 200, the pressure limiting valve is a closed pressure limiting valve 500, the pressure limiting valve The valve 500 includes a valve body 3, the weight of the pressure limiting valve is 50-100 grams, the valve body 3 is formed with an exhaust chamber H with a lower end opening 1, and the exhaust pipe 200 extends into the exhaust chamber H, the top wall of the exhaust chamber H is provided with a valve core 4, the valve core 4 seals the exhaust port of the exhaust pipe 200, the side wall of the exhaust chamber H is provided with ribs, and the air flow of the exhaust pipe 200 is lifted The valve core 4 blows to the rib to drive the valve body 3 to rotate and exhaust, and the gap between the side wall of th...

Embodiment 2

[0039] The pressure limiting valve 600 of this embodiment can refer to Figure 5 In this embodiment, on the basis of the first embodiment, the upper end of the side wall of the exhaust chamber H is provided with a stepped portion 8 . That is, the stepped portion 8 is located at the joint between the side wall and the top wall of the exhaust chamber H. The upper end of the step portion 8 is in contact with the top wall of the exhaust chamber H, so that the step portion 8 can be easily manufactured out of the mold. Preferably, the exhaust port of the exhaust pipe 200 is lower than the step portion 8 , and since the valve core 4 seals the exhaust port of the exhaust pipe, the lowest point of the valve core 4 is lower than the step portion 8 . During high-pressure cooking, the gas in the exhaust pipe 200 is discharged after the valve core 4 is pushed up, and most of its initial direction is obliquely upward, and the step part 8 is just above the exhaust port, so the exhausted air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com