Novel gas spray nozzle

A nozzle and aerosol technology, which is applied in the field of new aerosol nozzles, can solve the problems of uneven gas-water mixing, large water particles, and poor spray dust suppression effect, and achieve reasonable gas-water mixing ratio, reasonable structure, and suppress humidification too much effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

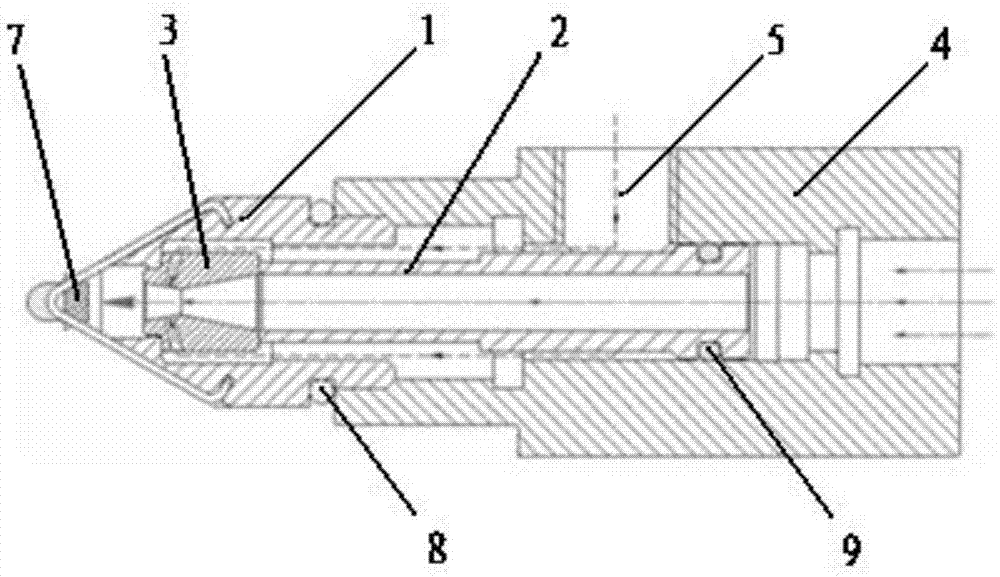

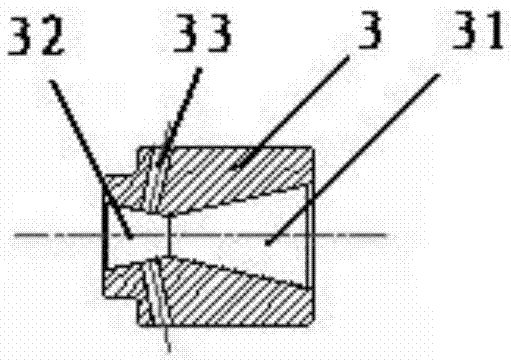

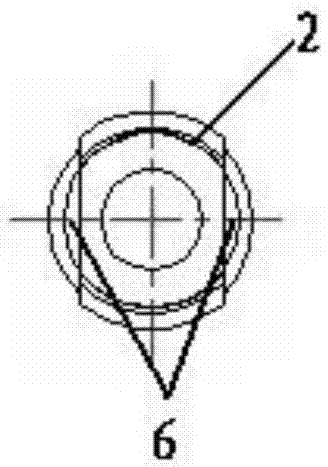

[0027] A new type of aerosol nozzle includes an aerosol nozzle body. The aerosol nozzle body includes a top cap 1, a tube shaft 2, a nozzle core 3, and a jacket 4. One side of the aerosol nozzle body is provided with a water inlet 5, and a top The cap 1 and the outer sleeve 4 are connected by external threads, the tube shaft 2 is installed inside the outer sleeve 4, and the top cap 1 and the tube shaft 2 are connected by internal threads. The riser 3 is closely attached to the top cap 1 and the tube shaft 2. At the same time, one end of the riser 3 is an air inlet cavity 31, and the other end of the riser 3 is a mixing cavity 32. The high-speed airflow enters the mixing cavity 32 of the riser 3 from the end interface of the aerosol nozzle body; 33. The small hole 33 passes through the mixing chamber 32. The pipe shaft 2 is provided with a keyway 6 at one end close to the shower core 3, so that there is space for the water flow to pass through the threaded connection between the ...

Embodiment 2

[0029] A new type of aerosol nozzle includes an aerosol nozzle body. The aerosol nozzle body includes a top cap 1, a tube shaft 2, a nozzle core 3, and a jacket 4. One side of the aerosol nozzle body is provided with a water inlet 5, and a top The cap 1 and the outer sleeve 4 are connected by external threads, the tube shaft 2 is installed inside the outer sleeve 4, the top cap 1 and the tube shaft 2 are connected by internal threads, and the riser 3 is closely attached to the top cap 1 and the tube shaft 2. At the same time, one end of the riser 3 is an air inlet cavity 31, and the other end of the riser 3 is a mixing cavity 32. The high-speed airflow enters the mixing cavity 32 of the riser 3 from the end interface of the main body of the aerosol nozzle; 33. The small hole 33 passes through the mixing chamber 32. The pipe shaft 2 is provided with a keyway 6 at one end close to the shower core 3, so that there is space for the water flow to pass through the threaded connection ...

Embodiment 3

[0031] A new type of aerosol nozzle includes an aerosol nozzle body. The aerosol nozzle body includes a top cap 1, a tube shaft 2, a nozzle core 3, and a jacket 4. One side of the aerosol nozzle body is provided with a water inlet 5, and the top The cap 1 and the outer sleeve 4 are connected by external threads, the tube shaft 2 is installed inside the outer sleeve 4, and the top cap 1 and the tube shaft 2 are connected by internal threads. The riser 3 is closely attached to the top cap 1 and the tube shaft 2. At the same time, one end of the riser 3 is an air inlet cavity 31, and the other end of the riser 3 is a mixing cavity 32. The high-speed airflow enters the mixing cavity 32 of the riser 3 from the end interface of the main body of the aerosol nozzle; 33. The small hole 33 passes through the mixing chamber 32. The pipe shaft 2 is provided with a keyway 6 at one end close to the shower core 3, so that there is space for the water flow to pass through the threaded connectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com