Pressure and flow-adjustable gas-liquid pulse pollution removing device

A gas-liquid pulse and adjustable technology, applied in the field of hydraulic pipeline cleaning, can solve the problems of low decontamination efficiency, difficult cleaning process, low gas-liquid mixing efficiency, etc., and achieve the effect of improving automation level and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

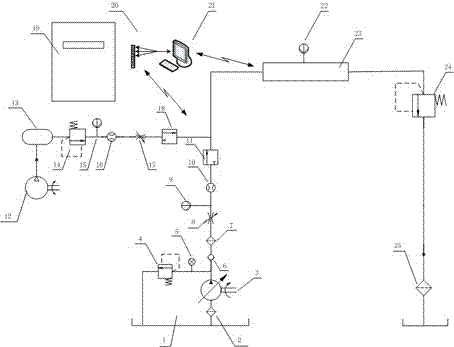

[0026] Such as figure 1 As shown, a gas-liquid pulse decontamination device with adjustable pressure and flow rate includes an electrical system, a pneumatic system and a hydraulic system. The electrical system includes a PLC control cabinet 19, an acquisition card 20 and a host computer 21. The PLC adopts Siemens PLC and expansion modules; the pneumatic system includes an air compressor 12, an air storage tank 13 and a pneumatic circuit, and the exhaust end of the air compressor 12 is connected to the intake end of the air storage tank 13; the hydraulic system includes a liquid tank 1 , variable pump 3 and hydraulic circuit, the liquid in the liquid tank 1 can be oil, also can be other liquids with good cleaning function. The variable pump 3 is controlled by a frequency converter, and the liquid inlet end of the variable pump 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com