Plastic tray for spindles

A technology of plastic pallets and spindles, applied in rigid containers, containers, packaging, etc., can solve the problems of yarn breakage, spindle wear, poor impact resistance, etc., and achieve the effect of improving bearing capacity, reducing transportation costs, and improving transportation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

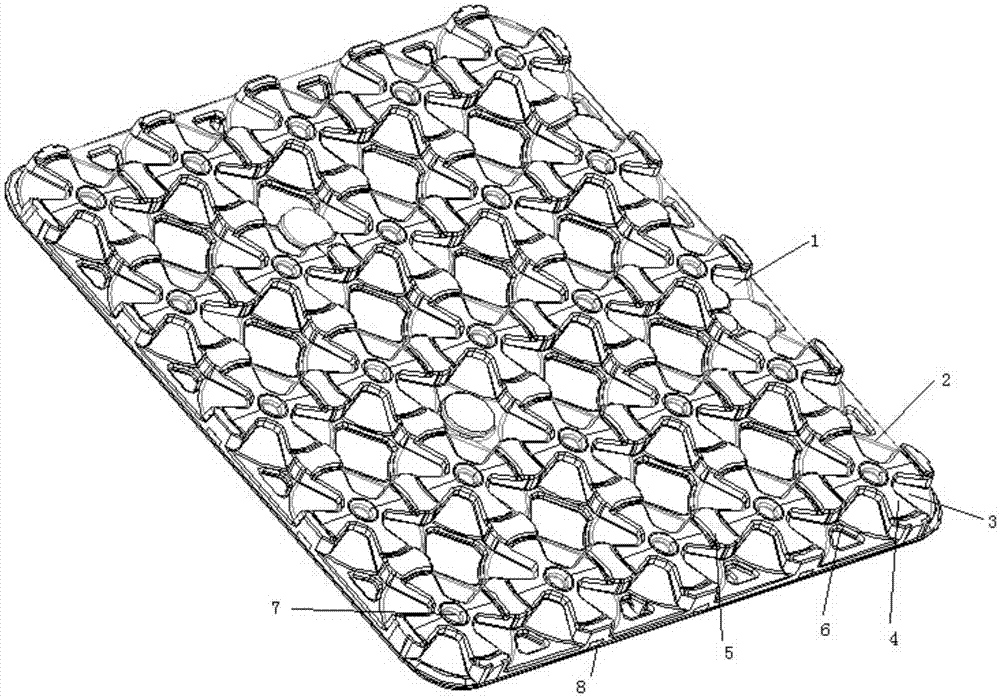

[0016] see figure 1 As shown, a plastic tray for yarn spindles has a base, a plurality of groups of trays 1 and a top cover; the base is provided with a tray 1, a layer of spindles is arranged between the two trays, and a The spindles are placed vertically, and the tray 1 is provided with longitudinally distributed cavities 2 for positioning the spindles. The cavity 2 has a circular recess 3, and protrusions 4 are distributed around the circular recess 3, and the protrusions 4 have a fan-shaped structure. A connecting portion 5 is provided between the two adjacent protrusions 4. A groove 6 is provided between the two circular recesses 3 on the edge of the tray 1, and the groove 6 is a base for inserting the tray 1. The tray 1 has four grooves 6 in the transverse and longitudinal directions. The center of the circular recess 3 has a circular recess 7. A vertical direction bar 8 is provided on the side of the tray 1.

[0017] The specific embodiments described above further de...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap