Pneumatic pipe continuous transferring system

A technology of transmission system and pneumatic pipeline, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problem of low transmission efficiency, and achieve the effect of improving transmission efficiency and increasing transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

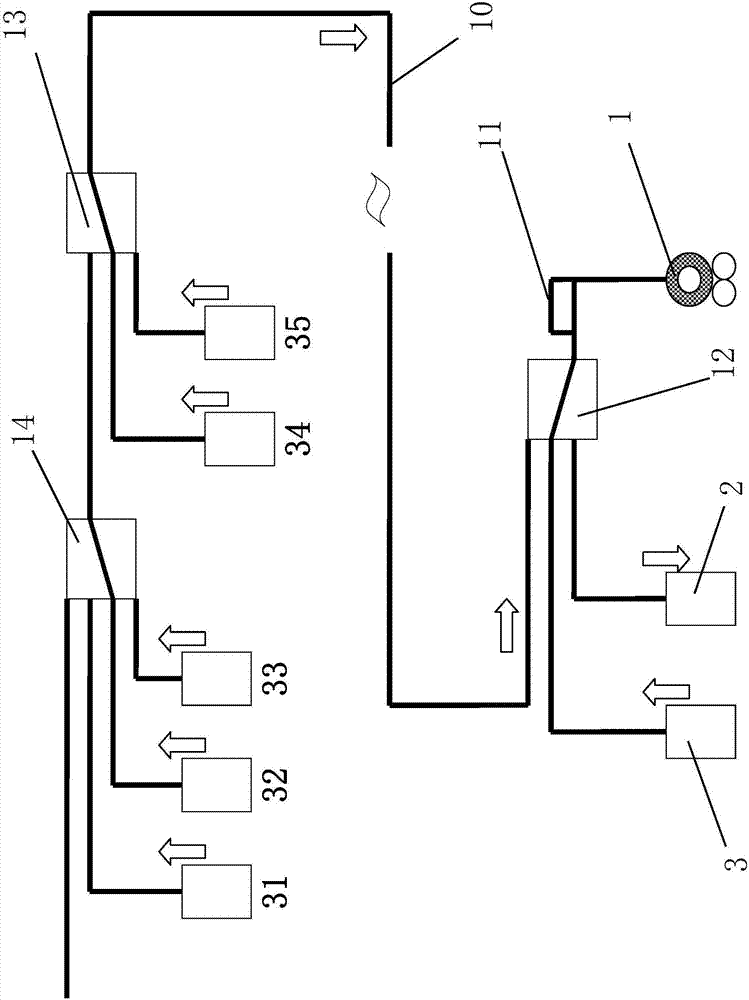

[0035] This embodiment discloses a pneumatic pipeline continuous transmission system, including a receiving workstation 2, a sending workstation 31 and a main fan 1, the receiving workstation 2 and the sending workstation 31 are connected through a main pipeline 10, and the receiving workstation 2 and the sending workstation 31 are connected to a storage converter 12 through the main pipeline 10, and then connected to the main fan 1 after passing through the storage converter 12, and on the main pipeline 10 between the main fan 1 and the storage converter 12 A main bypass pipe 11 is also provided.

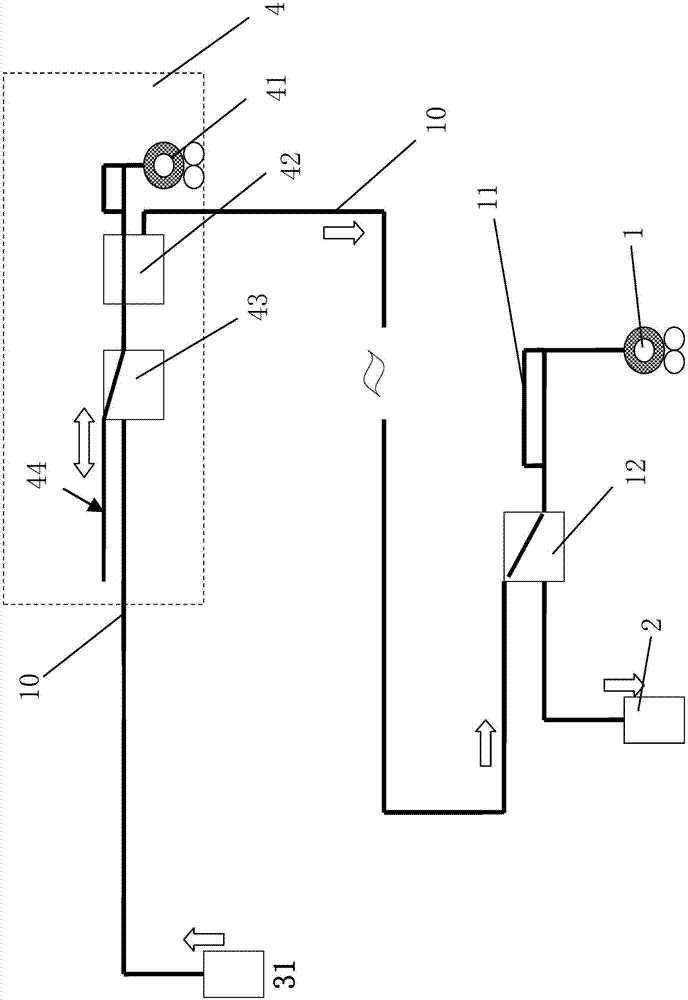

[0036] The main pipeline 1 is connected in series with a relay transceiver system 4, and the relay transceiver system 4 includes a first converter 43, a second converter 42, a temporary storage pipeline 44 and a relay fan 41:

[0037] The first and second converters 43, 42 are first connected in series, and then connected in series to the main pipeline 10, the temporary storage pip...

Embodiment 2

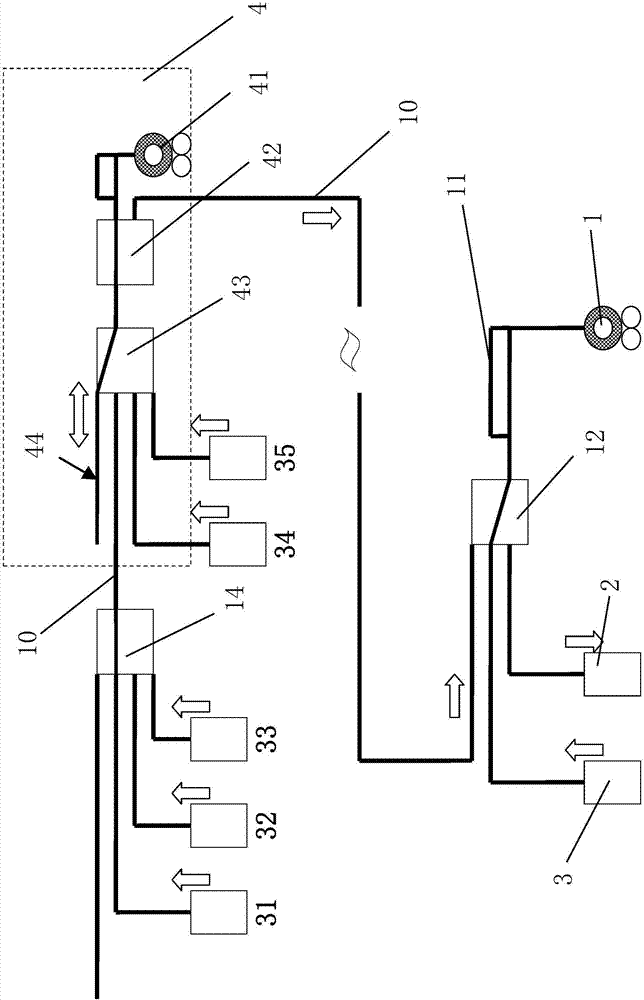

[0045] combine image 3 As shown, this embodiment discloses a pneumatic pipeline continuous transmission system, including receiving workstation 2, sending workstation 3, sending workstations 31-35, main fan 1, receiving workstation 2 and each sending workstation are connected through a main pipeline 10, and The receiving workstation 2 and each sending workstation are connected to the main fan 1 through the main pipeline 10; specifically, the main fan 1 is sequentially connected in series with a storage converter 12 and a four-way converter 14 through the main pipeline 10, and then through the storage The converter 12 and the four-way converter 14 are connected to each sending workstation and receiving work 2; in this embodiment, the main bypass pipe 11 is also provided to realize the receiving and sending of the transmission.

[0046] A relay transceiver system 4 is also connected between the storage converter 12 and the four-way converter 14, and the relay transceiver system...

Embodiment 3

[0056] combine Figure 4 As shown, this embodiment is basically the same as embodiment two, and its main difference is:

[0057] In this embodiment, there are two temporary storage pipelines connected to the first converter 43, which are the temporary storage pipeline 44 and the temporary storage pipeline 45; and the main bypass pipe 11 is lengthened to meet the requirements of batch buffering for 2-4 transmissions. bottle.

[0058] If the total time T31+T32+T33+T34 of multiple stations in the transit transceiver system to the temporary storage area is still less than the batch transmission time TB (when the main bypass pipe 11 of the transit transceiver system is far away), more transit transceivers can be added System, when a transit transceiver system is full, it can continue to transmit to the next transit transceiver system.

[0059] The transfer bottles sent to the same destination station of the main bypass pipe 11, such as the receiving workstation 2, can be sent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com