A kind of two-phase titanium alloy microstructure refinement method

A microstructure and titanium alloy technology, applied in the field of material science, can solve the problems of high equipment and process requirements, brittle materials, etc., and achieve the effect of low equipment requirements, simple operation, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

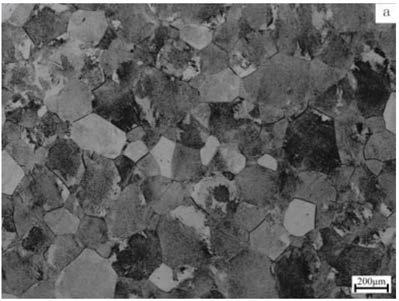

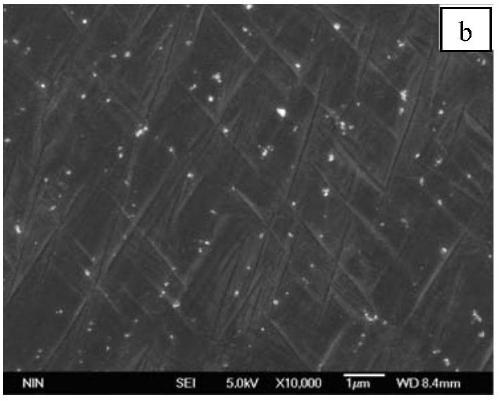

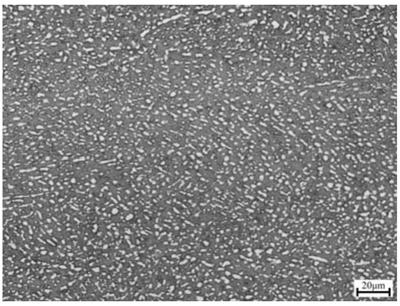

[0026] Take the 18mm slab processed by TC21 titanium alloy, raise the furnace temperature to 980°C, put the slab in the furnace for 10 minutes, and quench it in water to obtain a small and uniform equiaxed β crystal containing fine needle α phase. Granules (see attached Figure 1a , 1b ). Then put the slab in the electric resistance furnace, heat it for 10 minutes at a deformation temperature of 920°C for a short time, and then quickly roll it once. The deformation in the first pass is not less than 50%. After 50%, 65%, 80 After % deformation, water quenching, TC21 obtained a fine microstructure, after subsequent heat treatment, TC21 microstructure into a fine equiaxed structure, see attached figure 2 .

Embodiment 2

[0028] Take the 18mm slab processed by TC21 titanium alloy, raise the furnace temperature to 980°C, put the slab into the furnace and keep it warm for 10 minutes, quench it in water, and then preheat it in the resistance furnace, that is, keep it at the deformation temperature of 890°C for 10 Minutes, and then rapid one-fire rolling, the deformation of the first pass is not less than 50%, after 50%, 65%, 80% deformation, water quenching, TC21 has a fine microstructure, after subsequent heat treatment , TC21 microstructure is finer, see attached image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com