High-voltage electrostatic field floating air removing device

A high-voltage electrostatic field and floating hair technology, which is applied in the direction of removing floating yarn, can solve the problems of floating hair, lower fabric quality, and poor removal efficiency, and achieve good results, no noise pollution, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

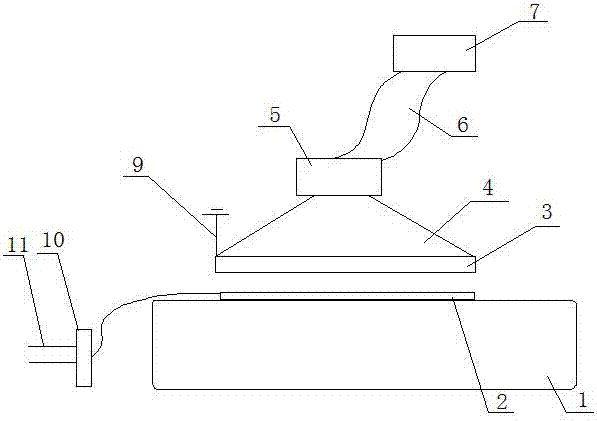

[0007] Such as figure 1 As shown, the present invention includes a fabric transmission guide belt 1, a conductive metal plate 2, a metal mesh plate 3, a fuzz receiving cover 4, a vacuum air compressor 5, a fuzz receiving pipeline 6, a hair storage device 7; a metal mesh plate 3 Set at the hair inlet of the floating hair receiving cover 4, the hair outlet of the floating hair receiving cover 4 is connected with the vacuum air compressor 5; the output end of the vacuum air compressor 5 is connected to the hair storage device 7 through the floating hair receiving pipe 6 Connection; the conductive metal plate 2 is set above the fabric transmission guide belt 1 through the bracket, and the conductive metal plate 2 is correspondingly arranged directly below the metal mesh plate 3. When in use, the fluffy fabric is transmitted to the metal mesh plate 3 and the Between the conductive metal plates 2; the metal mesh plate 3 is connected with a grounding wire 9; the conductive metal plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com