Drive belt with a set of nested steel flexible rings

A transmission belt, flexible technology, applied in the field of transmission belt, can solve impossible and very expensive problems, and achieve the effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

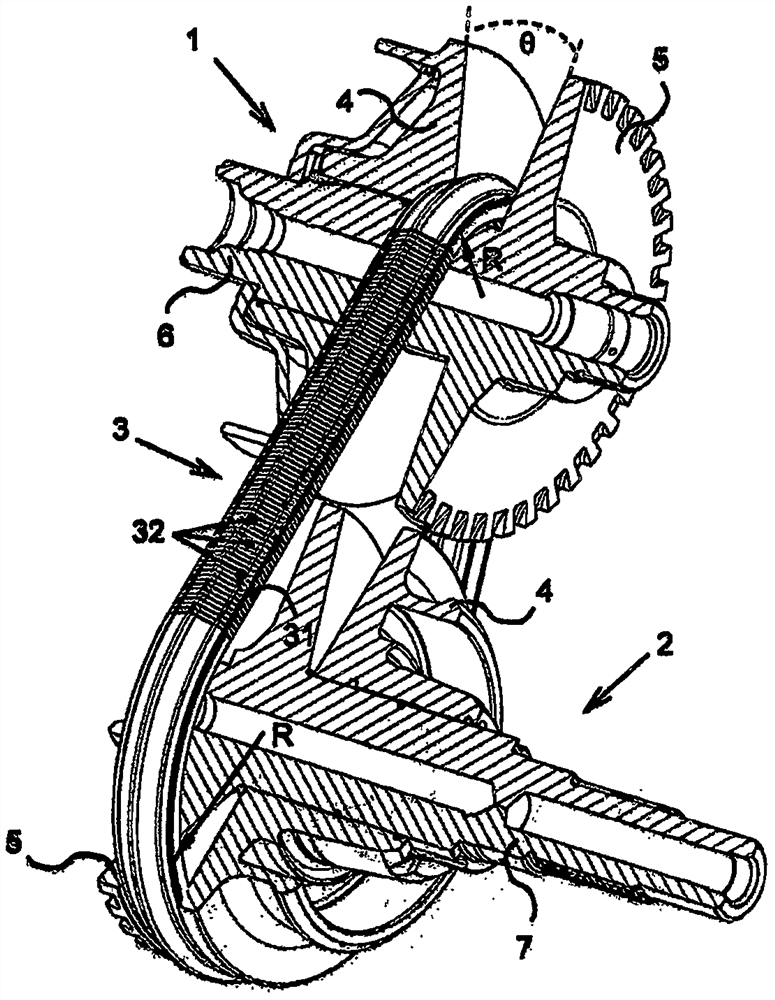

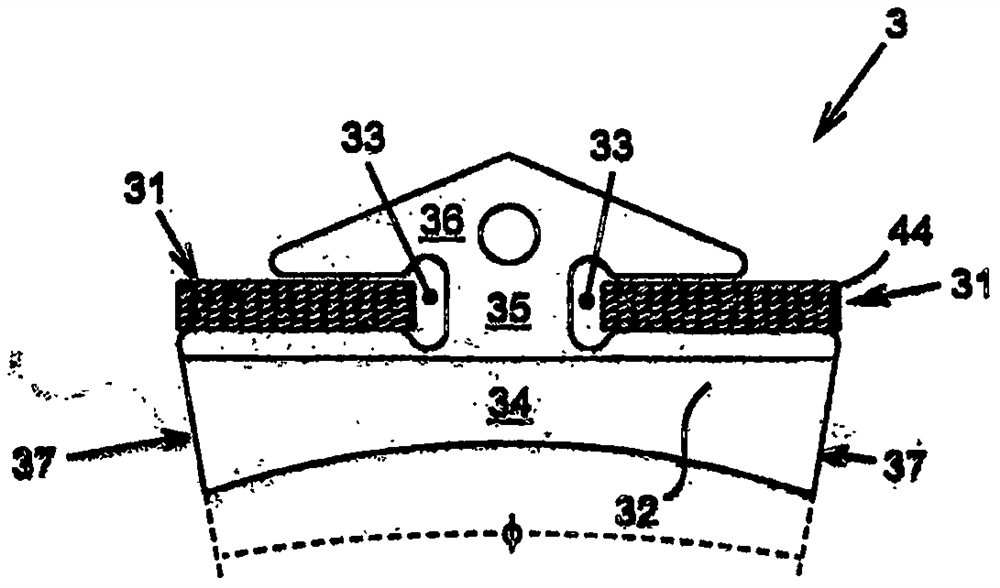

[0020] figure 1 The figure shows the central components of a known continuously variable transmission or CVT, which is commonly used in a motor vehicle transmission between its engine and driven wheels. The variator comprises two pulleys 1, 2 each provided with a pair of tapered pulley discs 4, 5 mounted on a pulley shaft 6 or 7, between which a mainly V-shaped Circumferential wheel groove. At least one pulley disk 4 of each pair of pulley disks 4 , 5 , ie of the pulley disks of each pulley 1 , 2 , is axially movable along the pulley shaft 6 , 7 of the corresponding pulley 1 , 2 . A drive belt 3 is wound around the pulleys 1 , 2 in pulley grooves for transmitting rotational motion and accompanying torque between the pulley shafts 6 , 7 .

[0021] The variator generally also comprises actuating means which, during operation, exert an axially directed clamping force on said axially displaceable pulley disc 4 of each pulley 1, 2, which force is directed towards the pulley 1, 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com