Micro mechanical property test clamping device for material under combined loading mode

A micromechanics and composite loading technology, applied in the direction of measuring devices, analytical materials, scientific instruments, etc., can solve problems such as complex force bearing methods and result deviations, achieve the effect of ensuring safety and data reliability, and increasing internal friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

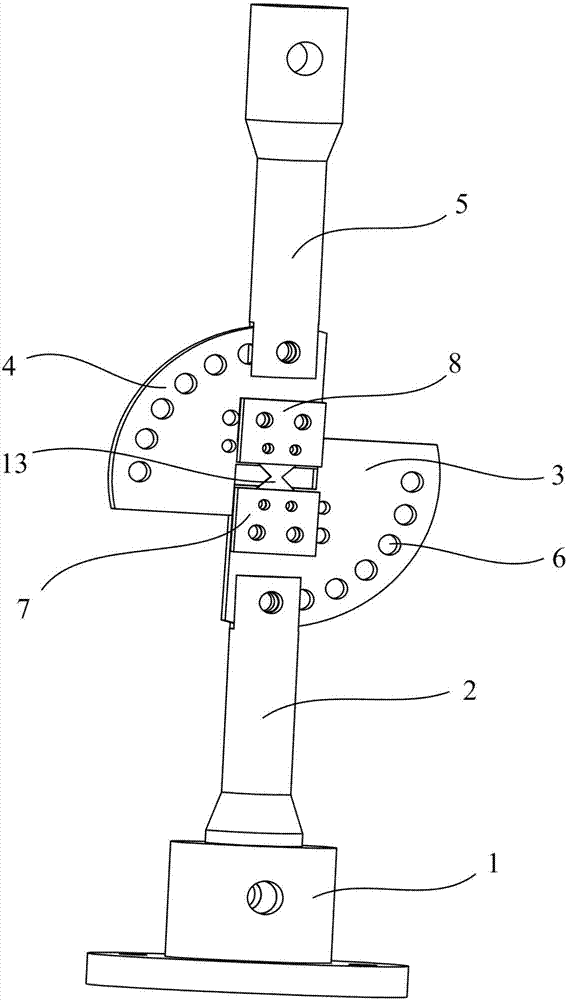

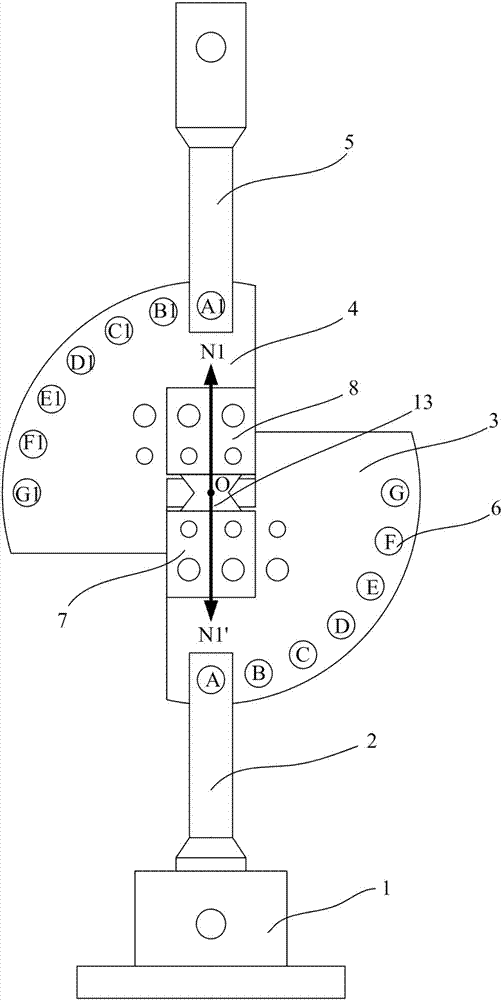

[0038] see figure 1 , in Embodiment 1 of the present invention, the clamping device includes a base 1 that can be fixedly installed on the top surface of the workbench, a lower connecting main shaft 2 connected to the top of the base 1, a lower fan-shaped flange 3 connected to the top of the lower connecting main shaft 2, The upper fan-shaped flange 4 located above the lower fan-shaped flange 3 and separated from the lower fan-shaped flange 3, and the upper connecting spindle 5 connected to the upper fan-shaped flange 4, the clamping device in the embodiment of the present invention also includes A clamping structure for clamping the test piece 13.

[0039] The clamping structure in the embodiment of the present invention includes a lower fixing block 7 for clamping one end of the test piece 13 and fixing it on the fan-shaped side of the lower fan-shaped flange 3, and a lower fixing block 7 for clamping the other end of the test piece 13 and fixing it on the upper fan-shaped f...

Embodiment 2

[0051] This embodiment is the same as Embodiment 1 except for the following features: the lower fixing block and the lower fan-shaped flange jointly clamp the opposite side of the test piece, and the upper fixing block and the upper fan-shaped flange jointly clamp The opposite sides of the holding specimen are equipped with micro-sawtooth structures.

[0052] In this embodiment, by setting the micro-sawtooth structure, the lower fixing block and the lower fan-shaped flange jointly clamp and fix one end of the test piece, and the upper fixing block and the upper fan-shaped flange jointly clamp and fix the other end of the test piece. , to prevent the specimen from loosening during the test and affect the actual test results.

Embodiment 3

[0054] This embodiment is identical with embodiment 1 except following feature:

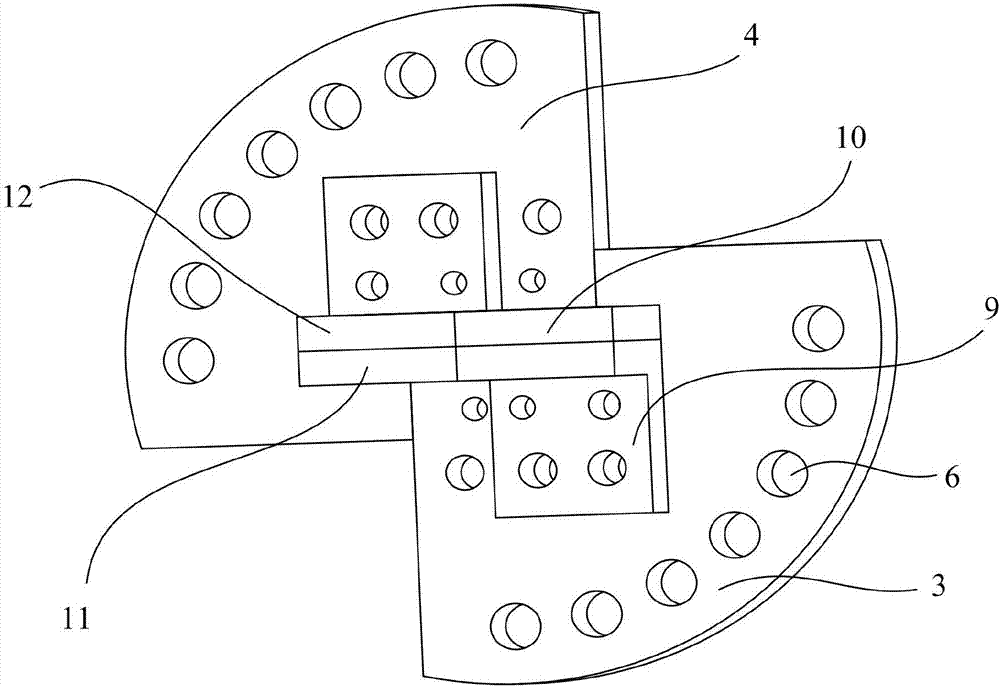

[0055] see figure 2 , the clamping structure includes a lower L-shaped fixed block 9 fixed on the fan-shaped side of the lower fan-shaped flange 3, a lower clamping block 10 connected to one end of the lower L-shaped fixed block 9 and capable of clamping one end of the test piece 13 , the upper L-shaped fixed block 12 that is fixed on the fan-shaped side of the upper fan-shaped flange 4, the upper clamping block 11 that is connected to one end of the upper L-shaped fixed block 12 and can clamp the other end of the test piece 13, the lower L The L-shaped fixing block 9 and the upper L-shaped fixing block 12 are symmetrical about the center and the side edges are flush.

[0056] see Figure 6 to Figure 8 , the lower clamping block 10 and the lower L-shaped fixing block 9 jointly clamp the opposite side of the test piece 13, and the upper clamping block 11 and the upper L-shaped fixing block 12 j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com