Infrared continuous zoom lens with long wave of 25 to 75mm and working method thereof

A zoom lens and long-wave infrared technology, applied in installation, optics, instruments, etc., can solve the problems of inaccurate quality control, difficult processing of diffractive surfaces, and inability to quantify detection, etc., to achieve excellent imaging quality, easy quality assurance, and small quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

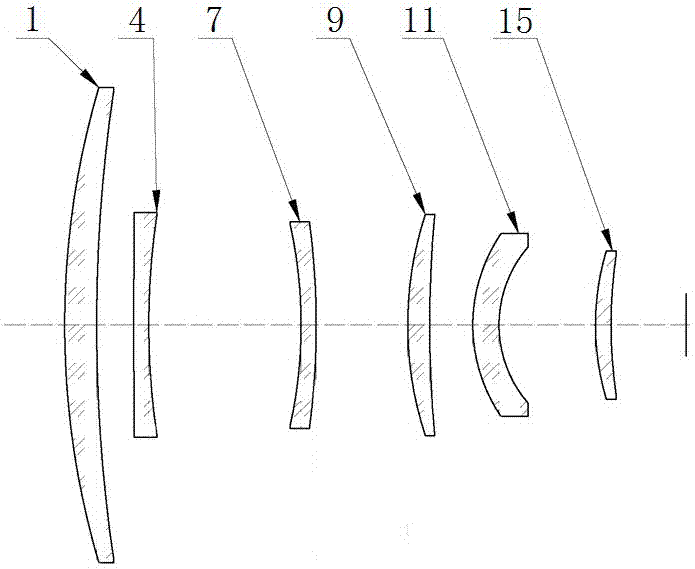

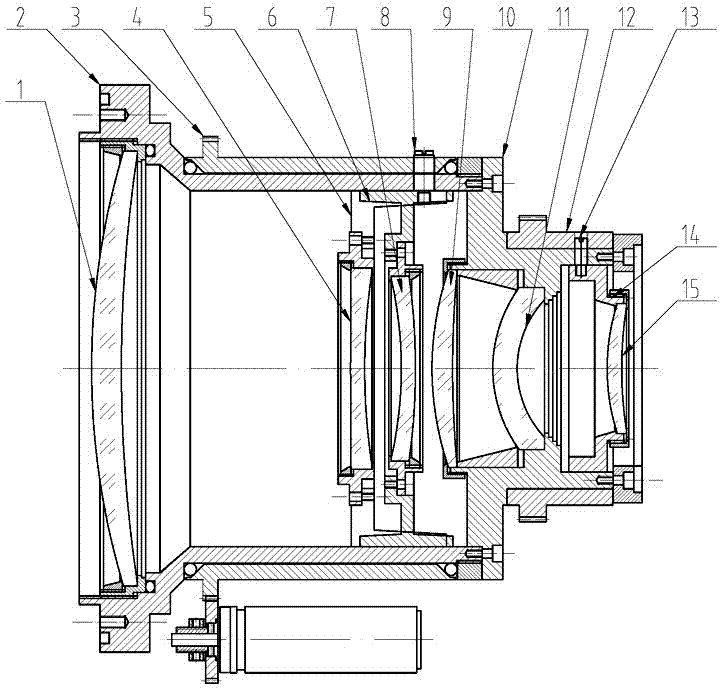

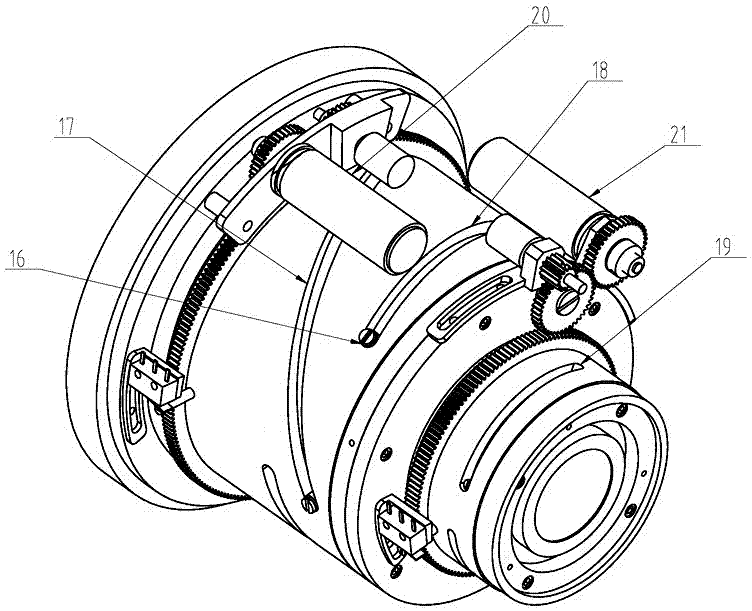

[0018] like Figure 1~4 As shown, a 25~75mm long-wave infrared continuous zoom lens, the optical system of the lens is provided with a front solid group lens A, a front zoom group lens B, a compensation group lens C, and a rear lens along the incident direction of light from front to back. The fixed group lens D and the focusing group lens E, the front fixed group lens A includes a positive crescent lens A-1 with a convex surface facing forward; the variable power group lens B includes a negative crescent lens B with a convex surface facing forward -1; the compensation group lens C includes a negative crescent lens C-1 with a concave surface facing forward; the rear fixation lens D includes a positive crescent lens D-1 with a convex surface facing forward and a positive crescent lens D- 1 Negative crescent lens D-2 on the rear side with the convex surface facing forward; the focusing group lens E includes a positive crescent lens E-1 with the convex surface facing forward.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com