Material distributing trolley assembly of building block forming machine

The technology of a material distribution vehicle and a block machine, which is applied in the direction of supply devices and manufacturing tools, can solve the problems of inconvenient maintenance of the mechanical structure of the material distribution vehicle, unbalanced distribution of the material distribution vehicle, and inflexible mechanical movements, etc., to achieve daily material cleaning and maintenance. Easy maintenance, reduced frame cracking, and good stress points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

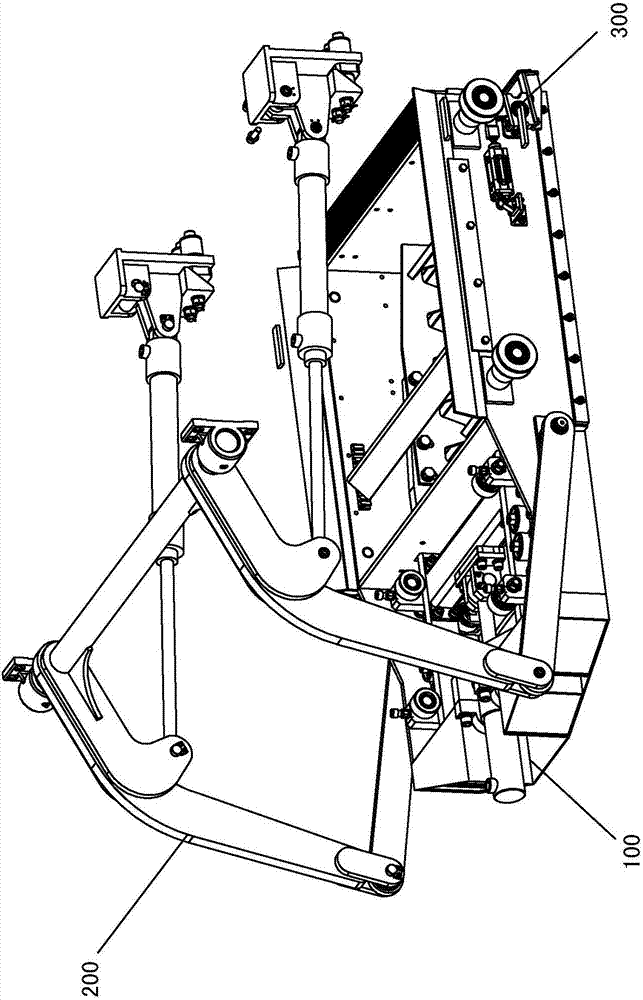

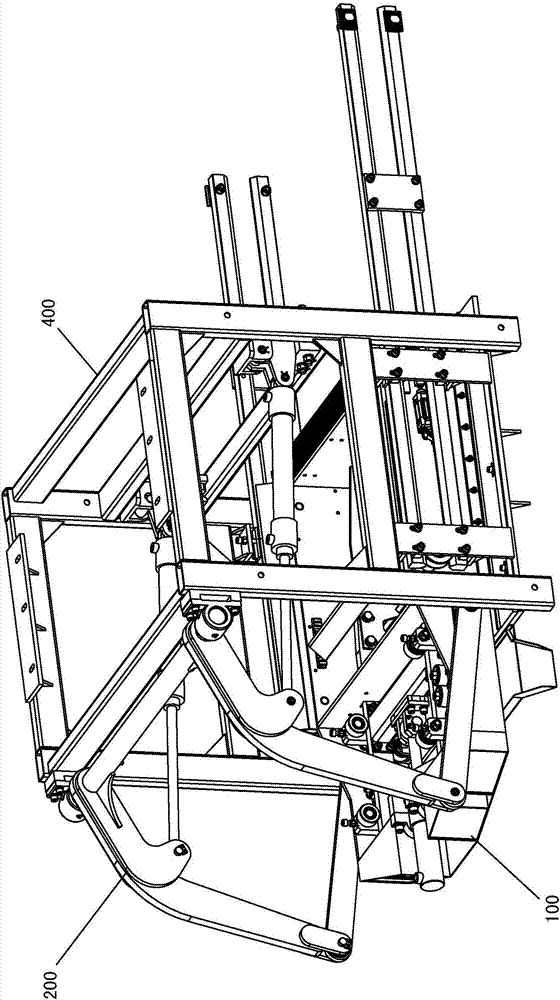

[0039] Such as figure 1 with figure 2 As shown, a material distribution vehicle assembly of a block machine according to the present invention includes a material distribution vehicle 100 , an advance and retreat buffer mechanism 200 that pushes the material distribution vehicle 100 to move forward and backward, a material cleaning device 300 and a frame 400 .

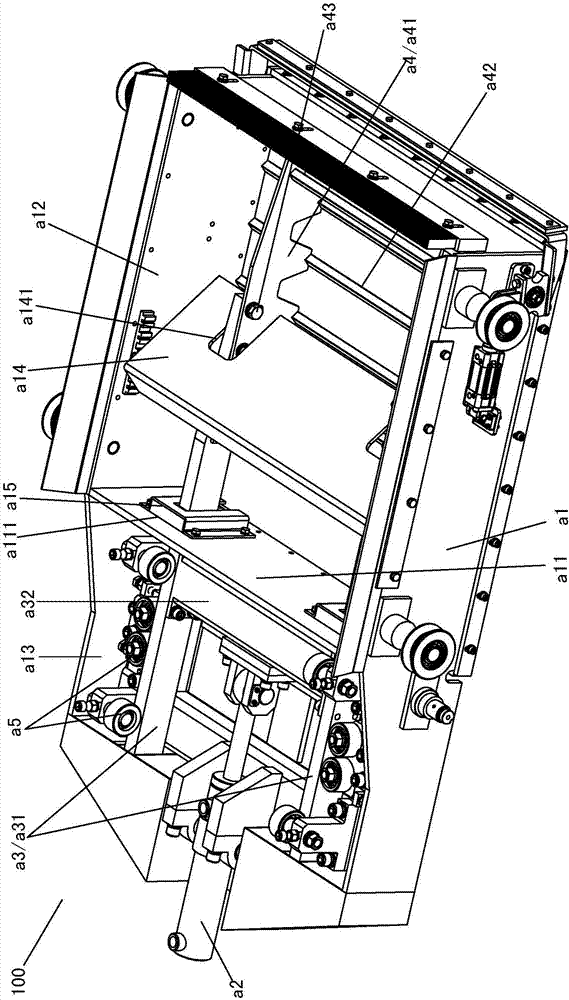

[0040] The cloth cart 100, such as figure 1 , figure 2 with image 3 As shown, it includes fabric frame a1, push-pull cylinder a2, rail frame a3 and fabric frame a4, such as figure 2 with image 3 As shown, the distribution vehicle frame a1 is erected on the frame 400 track of the block machine, and the distribution vehicle frame a1 is provided with a partition a11 to divide the distribution vehicle frame a1 into a distribution area a12 and a pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com