Exhaust pipe conveying device placed behind pipe cutting machine

A technology for conveying devices and exhaust pipes, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve problems such as damage, collision of pipe end collection boxes, etc., and achieve the effect of smooth friction and easy release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

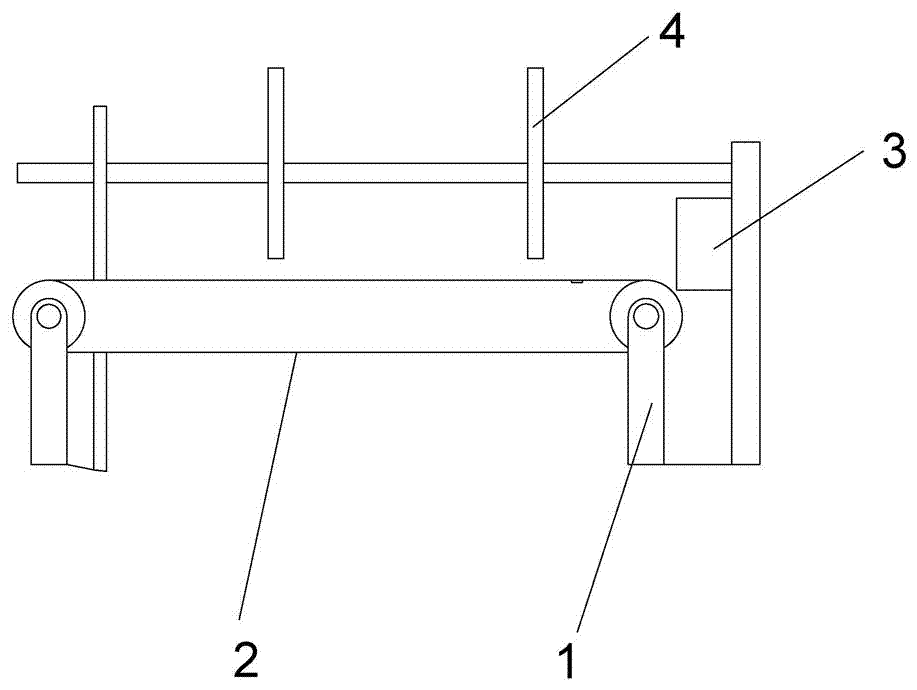

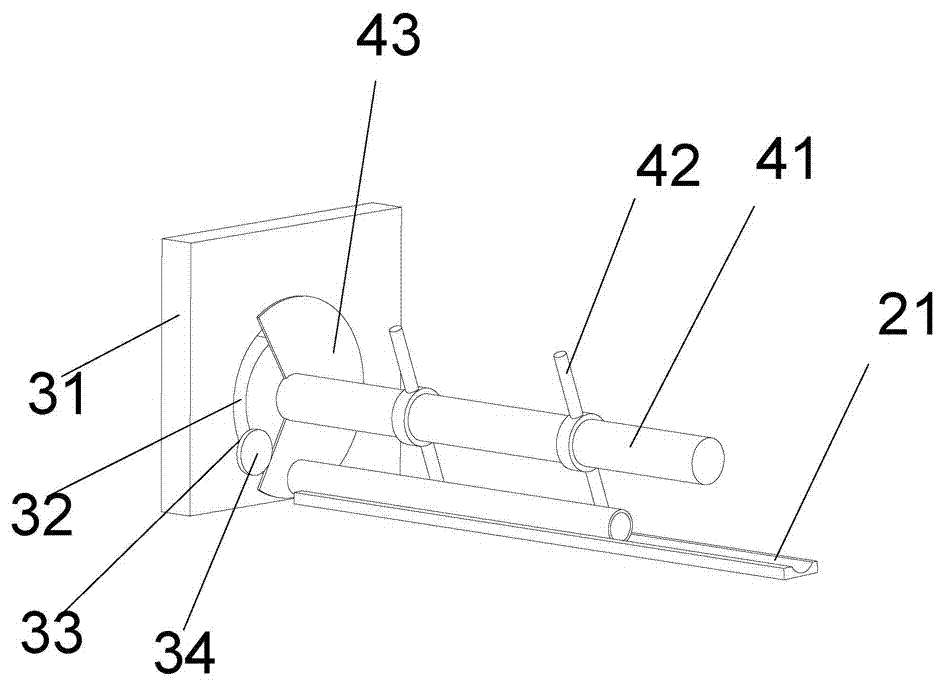

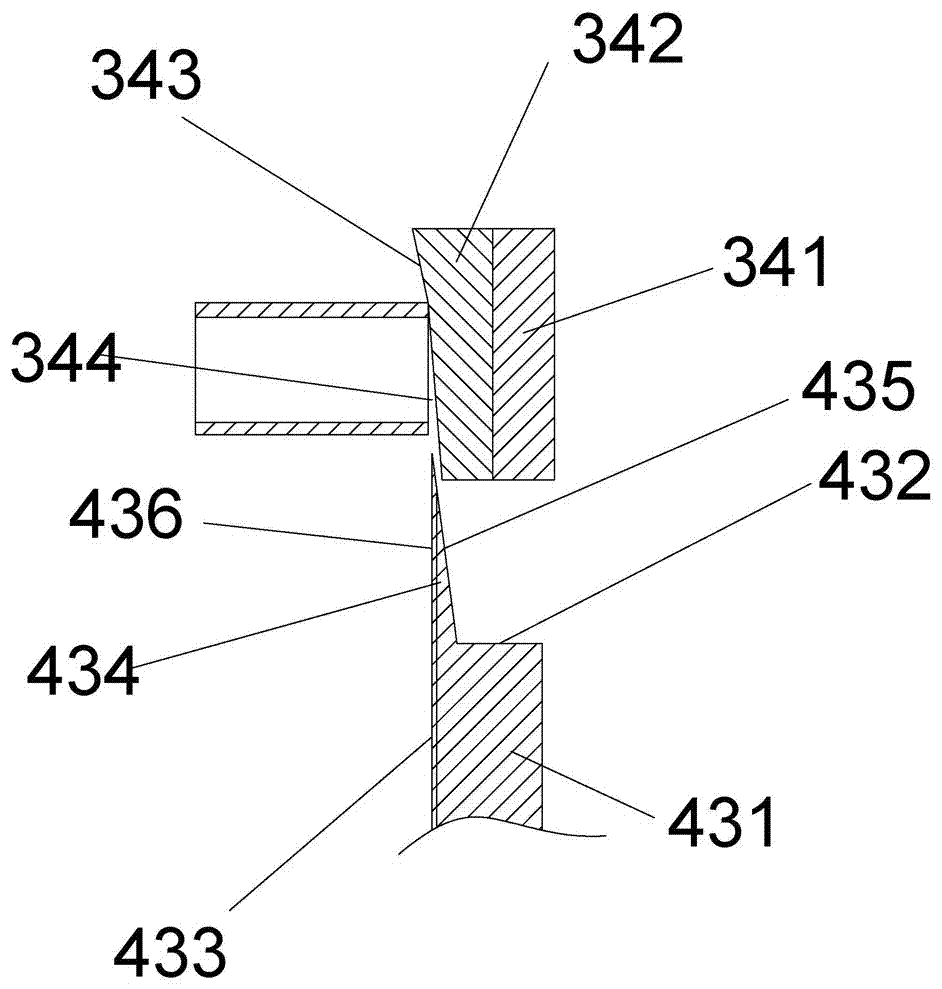

[0021] Embodiment 1: as Figure 1-3 As shown, an exhaust pipe conveying device placed behind the pipe cutter includes a frame 1, a horizontal conveyor belt 2 arranged on the frame 1, and a conveyor belt 2 at the discharge end of the conveyor belt 2. Buffered blocking device 3, a stirring device 4 provided on the frame 1 for moving the blocked exhaust pipe so that the exhaust pipe is perpendicular to the axial direction and output horizontally, and the horizontal conveyor belt 2 has Circular conveying trough 21.

[0022] In this device, the pipe cut by the pipe cutter falls into the conveying groove 21 on the horizontal conveyor belt 2, and the horizontal conveyor belt 2 drives the pipe forward, and collides with the blocking device 3 at the discharge end. During the collision, The flexible deformation of the blocking device 3 plays a buffering role on the pipe to prevent damage to the pipe. After the pipe is stabilized, the toggle device 4 moves the pipe to roll out of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com