Method for washroom reserved hole film template reuse positioning construction

A construction method and toilet technology, which is applied in the field of reuse and positioning construction of film templates for reserved holes in toilets, can solve the problems of high drainage construction costs, etc., and achieve the effects of saving positioning time, shortening work cycles, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A construction method for reuse and positioning of film templates for reserved holes in toilets, comprising the following steps:

[0039] S1: Plan the positioning of the drainage pipe in combination with the typesetting of the bathroom facing tiles, and then use the computer-aided technology support film template for backup:

[0040] S2: Set up the floor mold on the construction site and determine the reference point / reference line, and then lay the film template along the reference point / reference line to locate all the reserved holes;

[0041] S3: Use the drainage hole reserved pipe to fix the reserved hole, and then remove the film template to complete the positioning of the single bathroom reserved hole;

[0042] S4: After binding the reinforcement on the floor mold, perform concrete pouring, and remove the floor mold after the concrete sets;

[0043] S5: Then carry out the construction of the drainage riser, and record the length of the drainage riser, and feed th...

Embodiment 2

[0057] The difference from Example 1 is that the cement strength in the concrete is 32.5 or 42.5.

[0058] The particle size of rice stone used in concrete is 5mm-8mm.

[0059] The pipe fittings are integrally formed PVC pipes.

[0060] The process used in this embodiment is to design the size of the film template and the position of the hole on the design drawing, and make it according to 1:1 by a computer die-cutting machine, and the film template for the bathroom reserved hole is ordinary 1100mm The 0.25mm transparent film coil is used for 1:1 stakeout of the reserved hole in the bathroom, with the drainage standpipe as the positioning reference point and the structural beam edge as the reference line, and then after the structural beam and slab formwork is completed and before the reinforcement is laid, Directly spread the film template on the wooden template to quickly complete the positioning; this method shortens the work that originally required two people to complete...

Embodiment 3

[0062] It differs from Embodiment 2 in that:

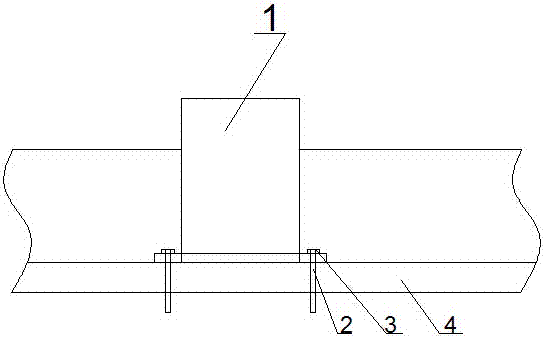

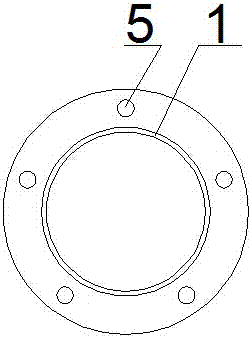

[0063] The drainage hole reserved pipe includes a reserved pipe, a through hole arranged on the lower end surface of the reserved pipe, and a bolt passing through the through hole and the through hole on the floor mold;

[0064] The two ends of the bolts are provided with cross or slotted screwdriver slots.

[0065] The lower end surface of the reserved pipe is located along the cross-crossing line of the diameter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com