Blowout prevention packer

A packer and blowout prevention technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., to reduce the risk of pipe string slippage, prevent blowout hazards, and realize the effect of ultra-high pressure blowout sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

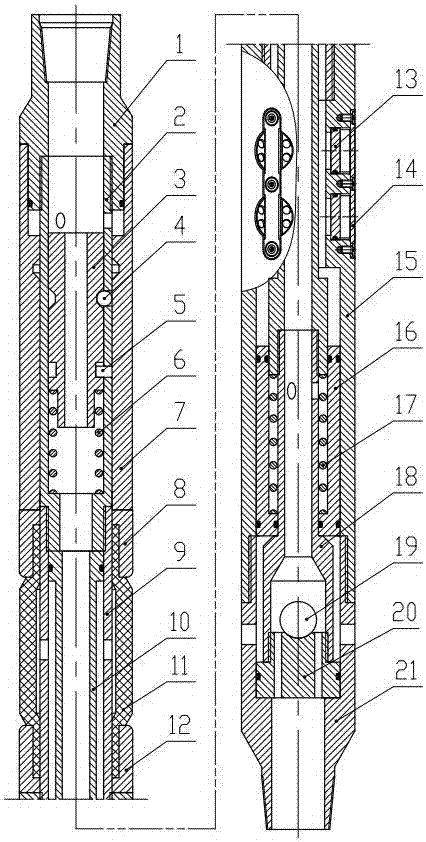

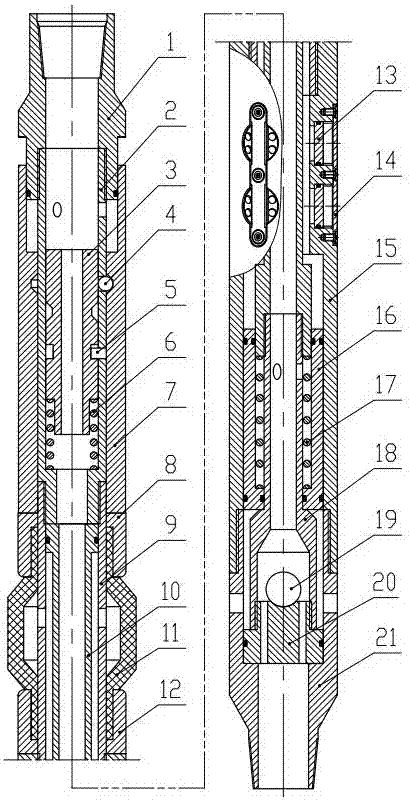

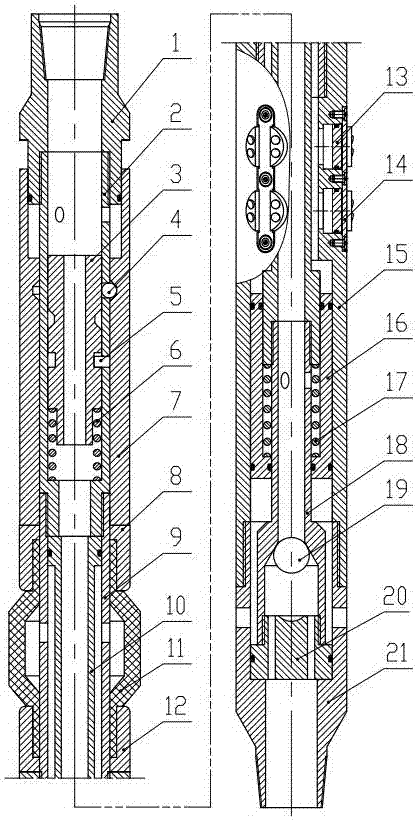

[0011] Such as figure 1 , figure 2 and image 3 As shown, a blowout prevention packer of the present invention is composed of an upper joint 1, a locking cylinder 2, a locking mandrel 3, a locking steel ball 4, a sliding pin 5, a locking spring 6, a pushing cylinder 7, an upper spacer ring 8, Connecting cylinder 9, oil seal mandrel 10, sealing rubber cylinder 11, lower spacer ring 12, anchor claw 13, cover plate 14, anchor cylinder 15, booster piston 16, return spring 17, sealing mandrel 18, sealing steel ball 19 , The ball seat 20 and the lower joint 21 are formed; its structural features are: the upper end of the upper joint 1 is connected with the upper pipe string screw, and the lower end of the lower joint 21 is connected with the lower drill string screw; the lower part of the outer circle of the upper joint 1 is set as a stepped shaft; The upper part of the locking cylinder 2 is evenly provided with three flow holes in the circumferential direction, the middle part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com