Feed discharging and stirring apparatus used for animal husbandry

A stirring device, animal husbandry technology, applied in the direction of mixer accessories, transportation and packaging, dissolution, etc., can solve the problems of inconvenient use, poor stirring effect, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

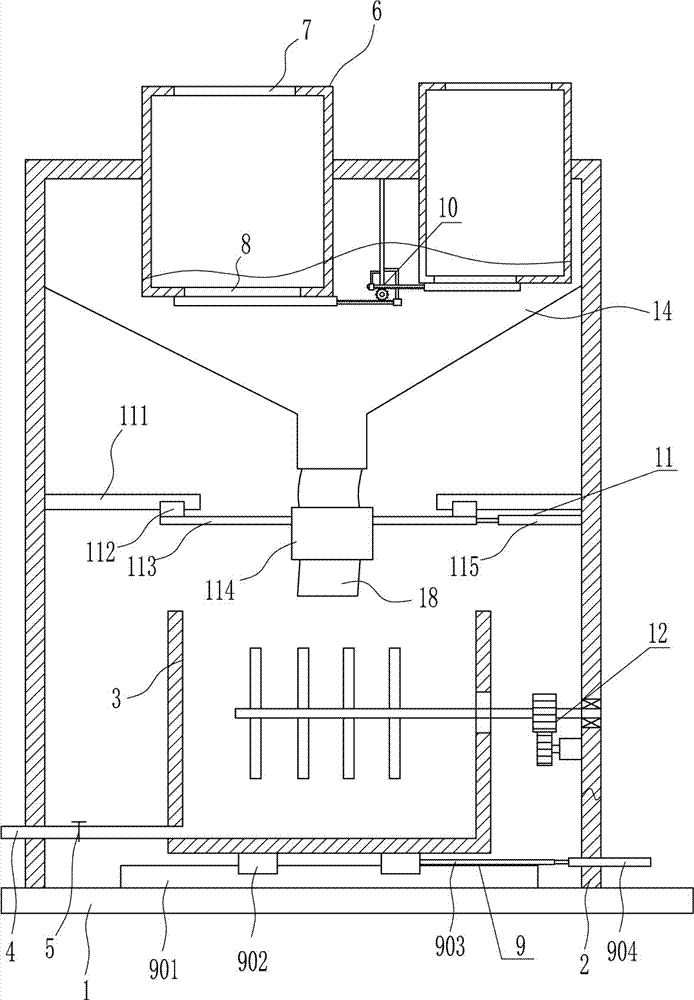

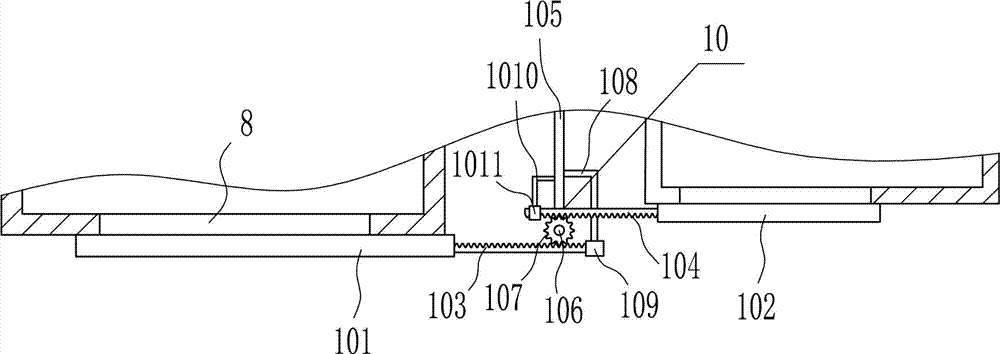

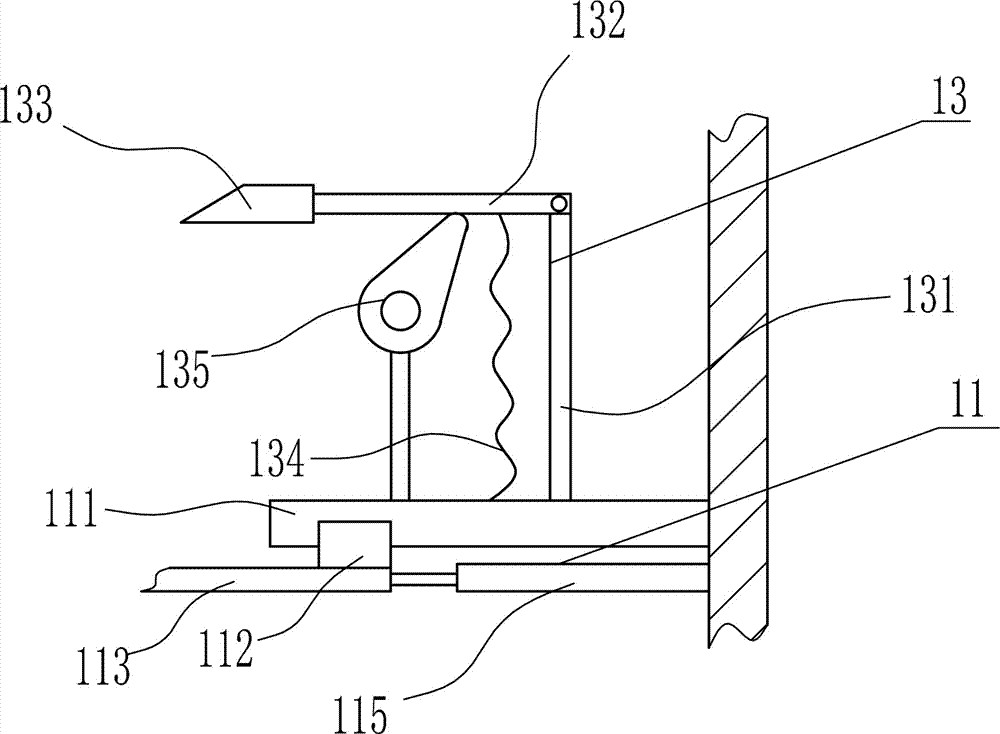

[0038] A kind of feeding stirring device for animal husbandry, such as Figure 1-8 As shown, it includes a bottom plate 1, an n-type bracket 2, a mixing box 3, a discharge pipe 4, a lower hopper 14, a valve 5, a first left and right moving device 9, a material retaining device 10, a placement box 6 and a hose 18, and the bottom plate 1 The top is welded with an n-type bracket 2, and the n-type bracket 2 is provided with a first left and right moving device 9, and the left and right moving parts of the first left and right moving device 9 are connected with a mixing box 3, and the left end of the mixing box 3 is welded with a discharge pipe 4, The discharge pipe 4 runs through the lower left side of the n-type support 2, the discharge pipe 4 is provided with a valve 5, and the right side of the n-type support 2 is symmetrically welded with a storage box 6, and the storage box 6 on the left is located in the storage box on the right 6 left rear side, the top of the storage box 6...

Embodiment 2

[0040] A feed feeding and stirring device for animal husbandry, such as Figure 1-8 As shown, it includes a bottom plate 1, an n-type bracket 2, a mixing box 3, a discharge pipe 4, a lower hopper 14, a valve 5, a first left and right moving device 9, a material retaining device 10, a placement box 6 and a hose 18, and the bottom plate 1 The top is welded with an n-type bracket 2, and the n-type bracket 2 is provided with a first left and right moving device 9, and the left and right moving parts of the first left and right moving device 9 are connected with a mixing box 3, and the left end of the mixing box 3 is welded with a discharge pipe 4, The discharge pipe 4 runs through the lower left side of the n-type support 2, the discharge pipe 4 is provided with a valve 5, and the right side of the n-type support 2 is symmetrically welded with a storage box 6, and the storage box 6 on the left is located in the storage box on the right 6 left rear side, the top of the storage box ...

Embodiment 3

[0043] A feed feeding and stirring device for animal husbandry, such as Figure 1-8 As shown, it includes a bottom plate 1, an n-type bracket 2, a mixing box 3, a discharge pipe 4, a lower hopper 14, a valve 5, a first left and right moving device 9, a material retaining device 10, a placement box 6 and a hose 18, and the bottom plate 1 The top is welded with an n-type bracket 2, and the n-type bracket 2 is provided with a first left and right moving device 9, and the left and right moving parts of the first left and right moving device 9 are connected with a mixing box 3, and the left end of the mixing box 3 is welded with a discharge pipe 4, The discharge pipe 4 runs through the lower left side of the n-type support 2, the discharge pipe 4 is provided with a valve 5, and the right side of the n-type support 2 is symmetrically welded with a storage box 6, and the storage box 6 on the left is located in the storage box on the right 6 left rear side, the top of the storage box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com