VC (vitamin C) adhesive diluting device for production of PTP (polyterephthalate) aluminum foils for medicine package

A dilution device and packaging technology, applied in transportation and packaging, mixers, shaking/oscillating/vibrating mixers, etc., can solve problems such as waste of raw materials, uneven mixing, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

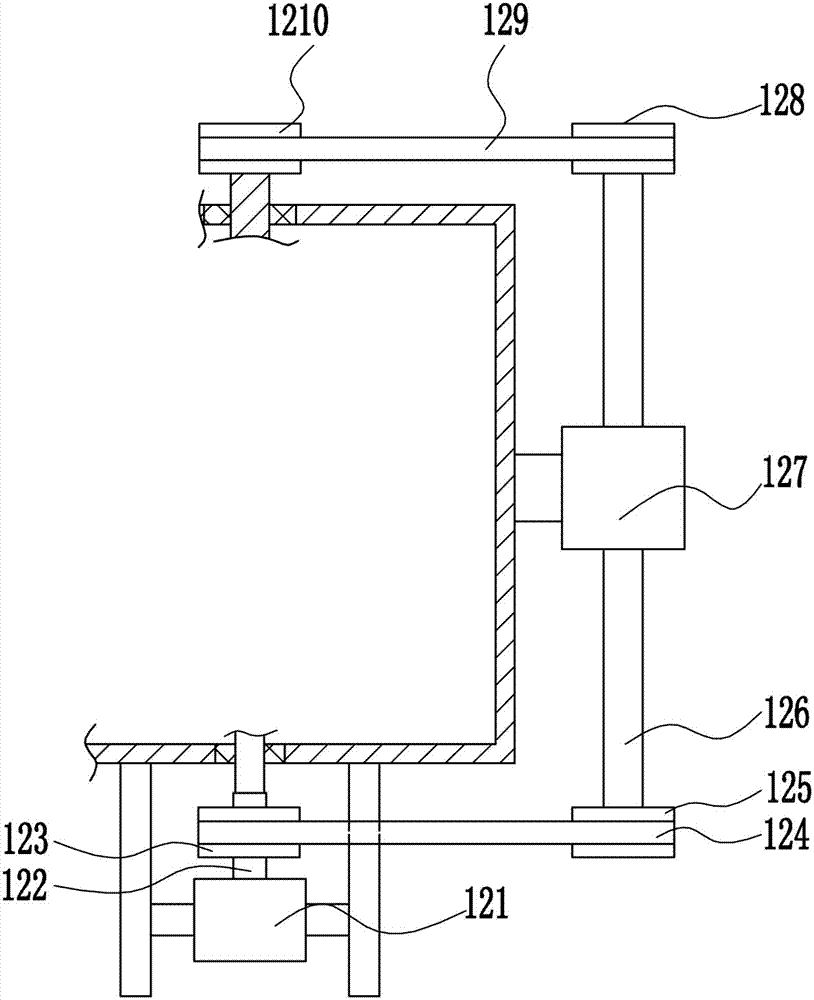

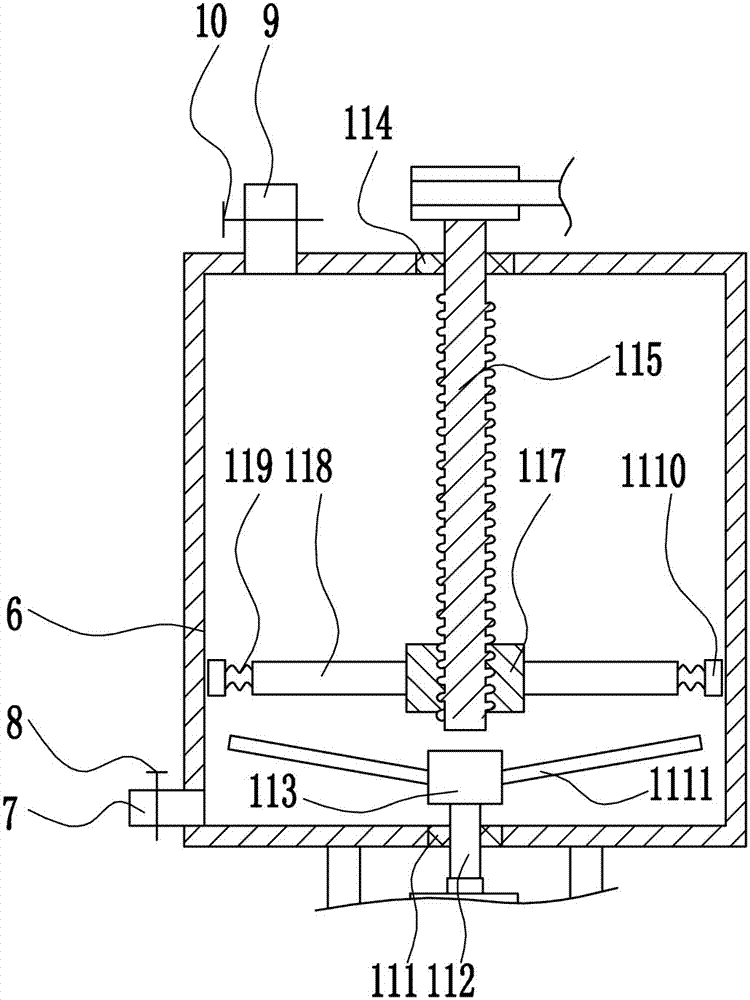

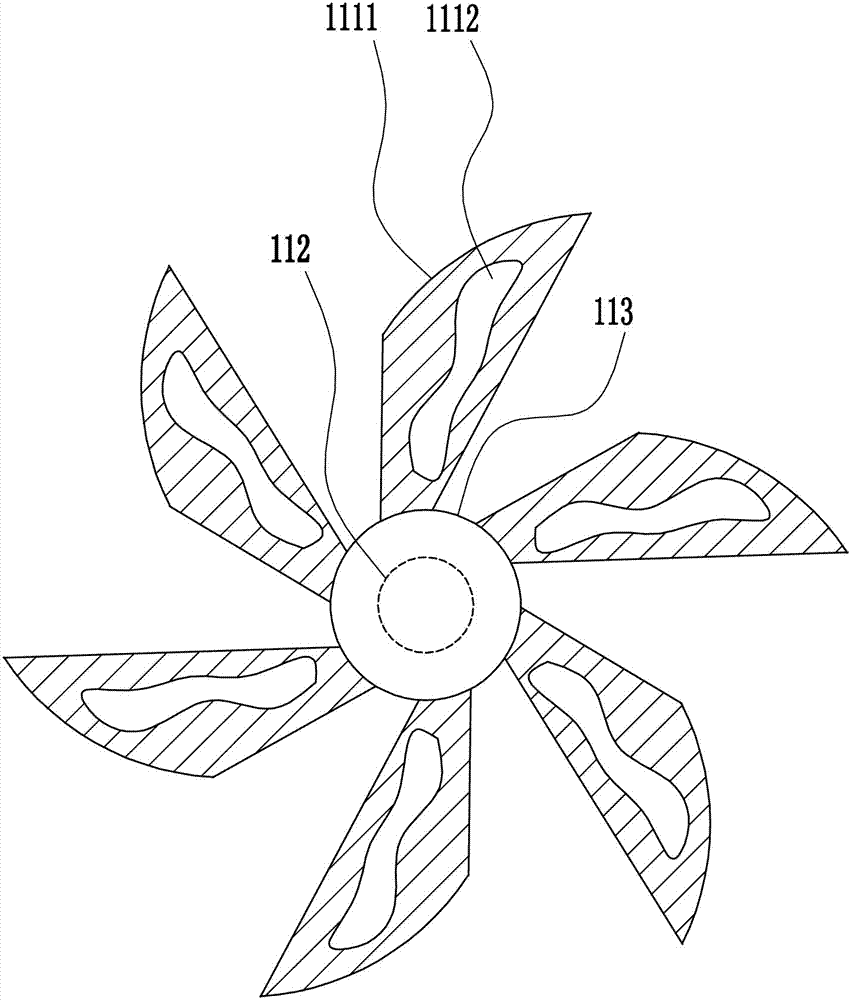

[0041] A VC adhesive dilution device for the production of PTP aluminum foil for medical packaging, such as Figure 1-8 As shown, it includes a bottom plate 1, a support frame 2, an arc-shaped slide rail 3, a first slider 4, a pole 5, a mixing bucket 6, a discharge pipe 7, a first valve 8, a feed pipe 9, and a second valve. 10. Stirring mechanism 11, rotating mechanism 12 and swinging mechanism 13, support frame 2 is installed on the top of bottom plate 1, arc-shaped slide rail 3 is connected to the upper end of support frame 2, and first slider 4 is slidably connected to arc-shaped slide rail 3 A strut 5 is installed on the first slider 4, and the upper end of the strut 5 is connected with a mixing tank 6, and the bottom plate 1 of the left wall of the mixing tank 6 is provided with a discharge pipe 7, and the discharge pipe 7 is provided with a first valve 8, There is a feed pipe 9 on the left side of the top of the mixing tank 6, a second valve 10 is provided on the feeding...

Embodiment 2

[0043] A VC adhesive dilution device for the production of PTP aluminum foil for medical packaging, such as Figure 1-8 As shown, it includes a bottom plate 1, a support frame 2, an arc-shaped slide rail 3, a first slider 4, a pole 5, a mixing bucket 6, a discharge pipe 7, a first valve 8, a feed pipe 9, and a second valve. 10. Stirring mechanism 11, rotating mechanism 12 and swinging mechanism 13, support frame 2 is installed on the top of bottom plate 1, arc-shaped slide rail 3 is connected to the upper end of support frame 2, and first slider 4 is slidably connected to arc-shaped slide rail 3 A strut 5 is installed on the first slider 4, and the upper end of the strut 5 is connected with a mixing tank 6, and the bottom plate 1 of the left wall of the mixing tank 6 is provided with a discharge pipe 7, and the discharge pipe 7 is provided with a first valve 8, There is a feed pipe 9 on the left side of the top of the mixing tank 6, a second valve 10 is provided on the feeding...

Embodiment 3

[0046] A VC adhesive dilution device for the production of PTP aluminum foil for medical packaging, such as Figure 1-8 As shown, it includes a bottom plate 1, a support frame 2, an arc-shaped slide rail 3, a first slider 4, a pole 5, a mixing bucket 6, a discharge pipe 7, a first valve 8, a feed pipe 9, and a second valve. 10. Stirring mechanism 11, rotating mechanism 12 and swinging mechanism 13, support frame 2 is installed on the top of bottom plate 1, arc-shaped slide rail 3 is connected to the upper end of support frame 2, and first slider 4 is slidably connected to arc-shaped slide rail 3 A strut 5 is installed on the first slider 4, and the upper end of the strut 5 is connected with a mixing tank 6, and the bottom plate 1 of the left wall of the mixing tank 6 is provided with a discharge pipe 7, and the discharge pipe 7 is provided with a first valve 8, There is a feed pipe 9 on the left side of the top of the mixing tank 6, a second valve 10 is provided on the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com