An automatic variable diameter cyclone separation device for overflow pipe

A technology of swirl separation device and overflow pipe, which is applied in the direction of swirl device and the device whose axial direction of swirl can be reversed, etc. It can solve the problem that it is difficult to adjust the overflow diversion rate of the overflow pipe diameter and the inability to maintain the diversion High efficiency, complex operation process and other issues, to achieve good separation effect, continuous and efficient separation, simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

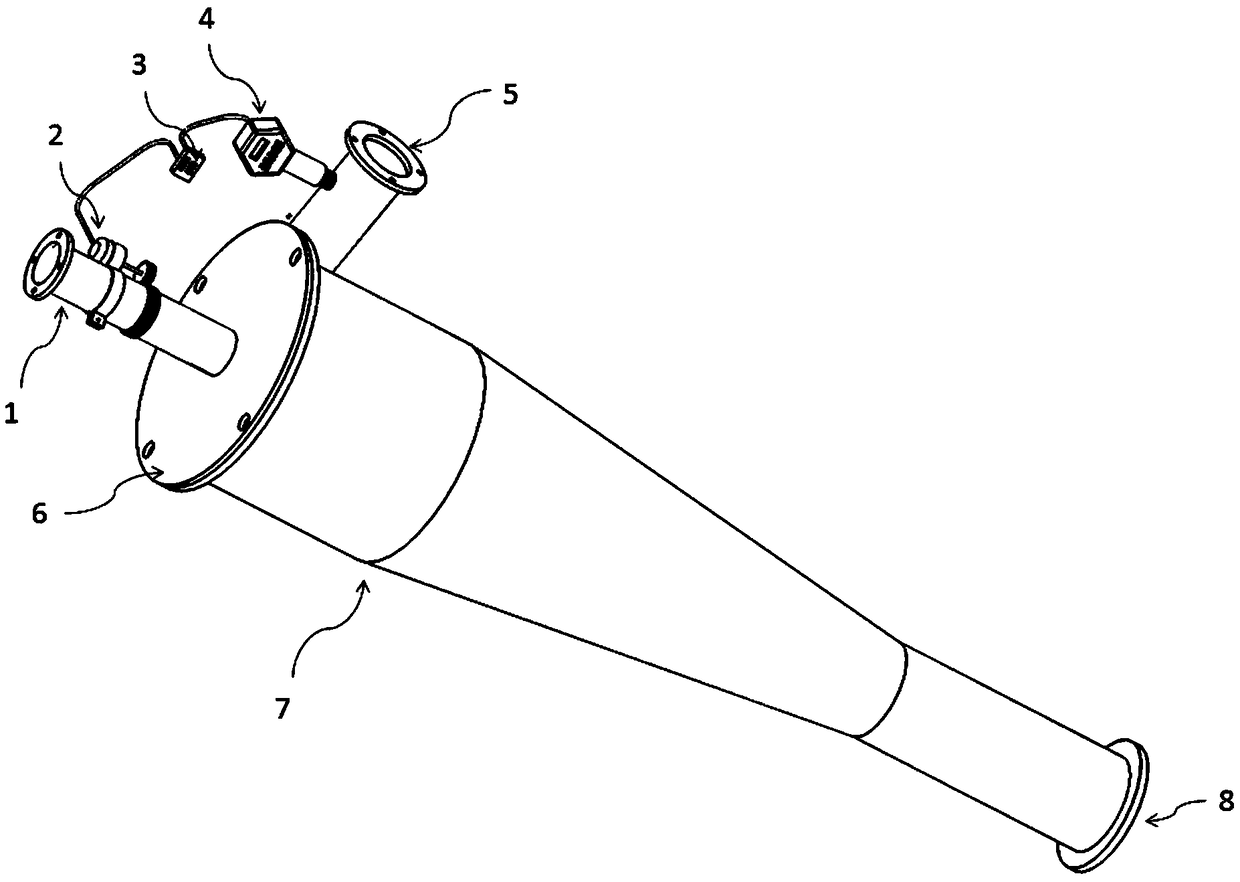

[0034] The overall appearance of this kind of overflow pipe automatic variable diameter cyclone separation device is as follows: figure 1 As shown, it is mainly composed of a variable-diameter overflow pipe 1, a diameter-adjusting motor 2, a controller 3, a pressure sensing device 4, a device inlet pipe 5, an upper sealing plate 6, a variable-diameter separation pipe 7, and an underflow pipe 8. The pressure sensing device 4 is threaded into the inlet pipe 5 of the device, and the pressure at the inlet is monitored as much as possible. At the same time, the measured pressure is transmitted to the controller 3 synchronously. The controller converts the signal into the number of rotations of the diameter-adjusting motor 2, and then The variable diameter overflow pipe 1 is adjusted for variable diameter.

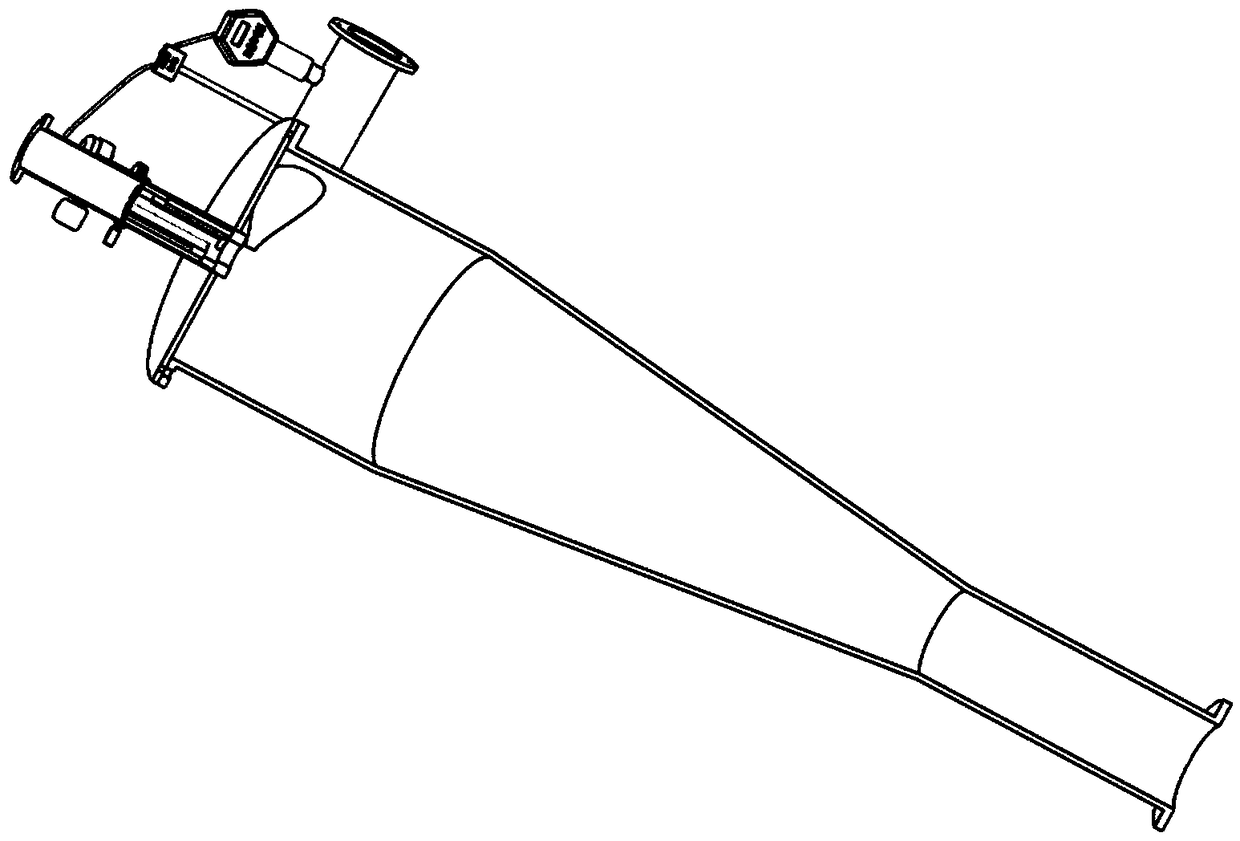

[0035] The internal sectional view of the device is shown in figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com