Multi-machine-head single-return-stroke segmented compression type water chilling unit

A technology of segmented compression and chiller, applied in compressors, compressors, irreversible cycle compressors, etc., can solve the problems of low cooling efficiency and unmatched chilled water flow and cooling capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

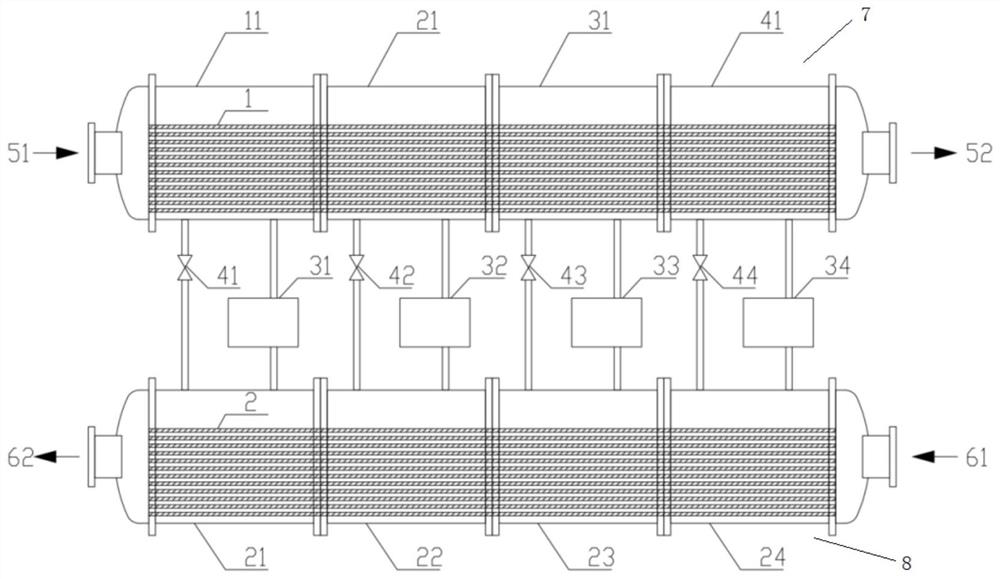

[0018] Such as figure 1 As shown, this embodiment provides a multi-head single-return segmental compression chiller, including a combined condenser 7 and a combined evaporator 8, and the combined condenser 7 is sequentially connected and combined by four segmented condensers. The two ends of the combined condenser 7 are respectively the condenser inlet 51 and the condenser outlet 52, and the four section condensers are respectively the first section condenser 11 and the second section condenser from the condenser inlet 51 to the condenser outlet 52. Sectional condenser 21, the third section condenser 31 and the fourth section condenser 41, the combined condenser 7 is provided with a condenser tube bundle 1 for common use by four section condensers, the combined evaporator 8 is composed of four segmented evaporators connected sequentially. The two ends of the combined evaporator 8 are the evaporator inlet 61 and the evaporator outlet 62 respectively. The four segmented evaporat...

Embodiment 2

[0023] In this embodiment, the water chiller provided in Example 1 is used as an example. First, according to the actual chilled water flow demand, the lengths of the condenser tube bundle 1 and the evaporator tube bundle 2 in the chiller in Example 1 are determined, that is, the cooling function The number of sections, four refrigeration function sections are selected in this embodiment.

[0024] During the operation of the chiller, according to the demand for terminal cooling capacity, the following conditions are met:

[0025] Case 1: When the cooling load is not greater than 25% of the rated cooling capacity of the chiller, choose to run only the first cooling function segment (or one of the other three cooling function segments), and the cooling water enters the condenser from the inlet 51 of the condenser The evaporator tube bundle 1 flows out from the condenser outlet 52 , and then the chilled water enters the evaporator tube bundle 2 from the evaporator inlet 61 and fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com