Steam pipeline pressurization system and full-automatic control method thereof

A technology of pressurization system and steam pipeline, applied in pipeline system, pump control, machine/engine, etc., can solve the problems of system hazards, system damage, complex structure, etc., to reduce operating costs, avoid factory maintenance costs, and save water The effect of electrical overhead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

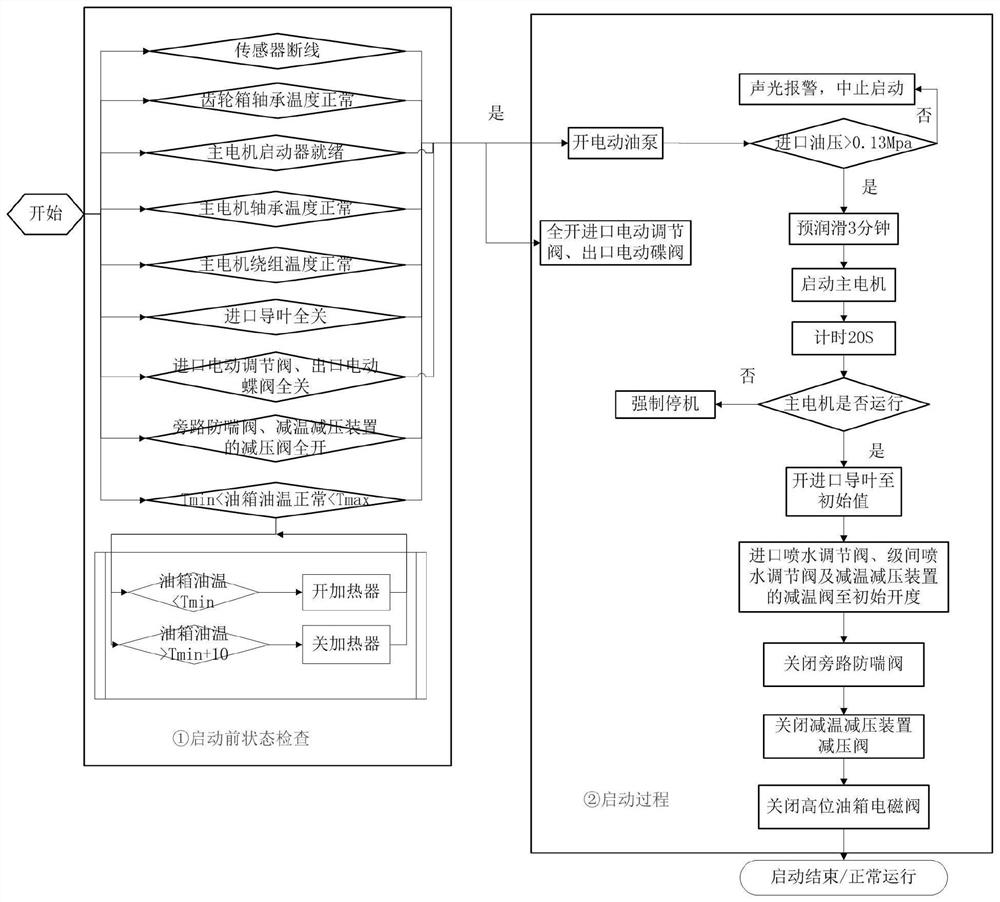

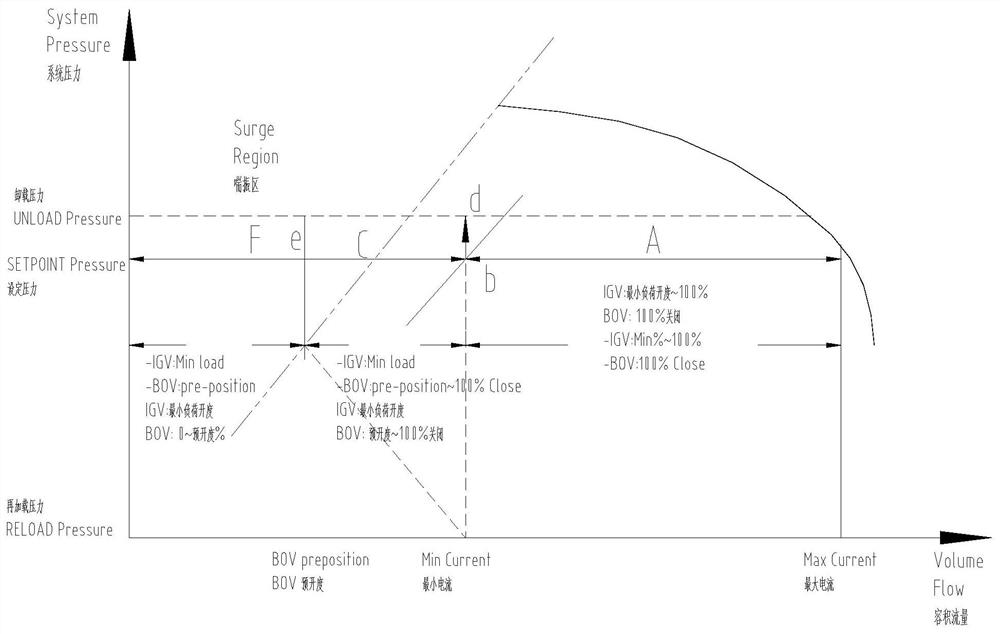

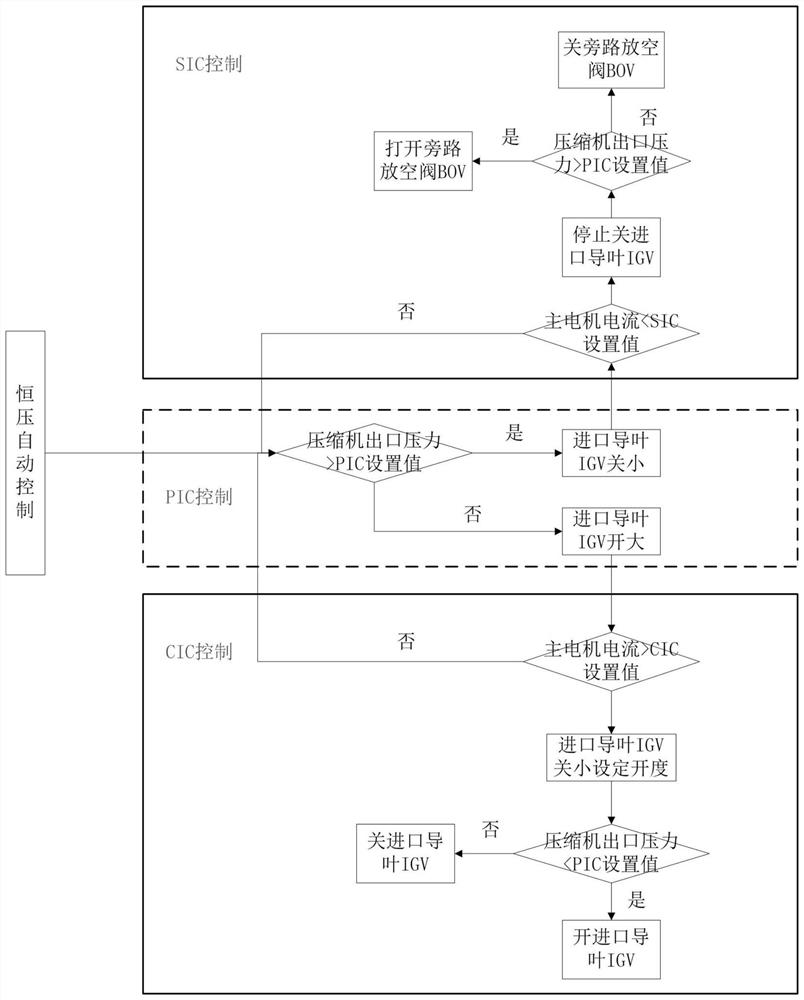

[0055] Below in conjunction with accompanying drawing, the present invention will be further described,

[0056] see Figure 1-Figure 8 , a steam pipeline pressurization system, including a steam inlet buffer tank 1 and an exhaust steam buffer tank 2, the steam inlet buffer tank 1 buffers the input primary low-pressure saturated steam, and the exhaust steam buffer tank 2 buffers the pressurized secondary The sub-saturated high-pressure steam is buffered, and the buffered secondary high-pressure saturated steam is incorporated into the main pipeline. The pressurization system further includes:

[0057] The inlet guide vane mechanism 3 is connected to the steam inlet buffer tank 1 through the steam inlet pipeline 4, and the steam inlet regulating valve 5 is arranged on the steam inlet pipeline 4, which is used to adjust the flow of low-pressure saturated steam entering the inlet guide vane mechanism;

[0058] The first stage 6 of the compressor is connected to the outlet end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com