Spraying supporting frame and a spraying device

A technology of spraying device and support frame, which is applied in the direction of spraying device, etc., can solve the problems of affecting the quality of casting high-precision centrifugal tube billet, uneven coating on the inner wall of mold cavity, and inability to ensure uniformity of spraying, so as to avoid instability , Conducive to spraying quality, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

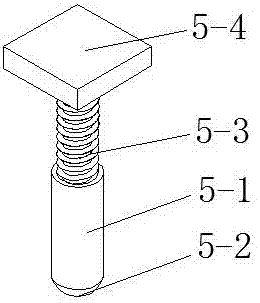

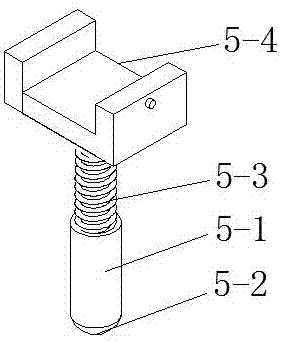

[0029] Such as figure 1 , figure 2 As shown, the spraying support frame includes a pole 5-1, which is provided with a height adjustment device on the pole 5-1, and a universal ball 5-2 is provided at the bottom of the pole 5-1; The threaded sleeve on the -1 and the telescopic rod 5-3 with external thread matched with the threaded sleeve.

[0030] Such as figure 1 , figure 2 As shown, the support frame also includes a support 5-4 arranged on the top of the pole 5-1, and the pole 5-1 is vertically fixed on the support 5-4; the top surface of the support 5-4 can be a plane structure, or It can be a groove structure. If the top of the support 5-4 is a plane structure, it is used to insert the push rod 1 into the groove that matches the plane structure; if the top of the support 5-4 is a groove structure, it is used to use The push rod 1 is inserted so that the support frame is fixed on the push rod 1.

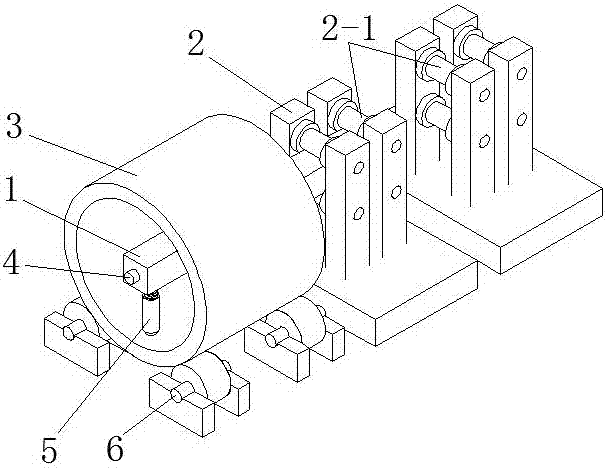

[0031] Such as image 3 , Figure 4 As shown, the spraying device for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com