Car walking rail device for annular object packing

A technology for walking tracks and objects, applied in the field of packaging, can solve problems such as difficulty in controlling flatness, large runway footprint, and runway occupancy, and achieve the effects of small footprint, smooth operation, no impact, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

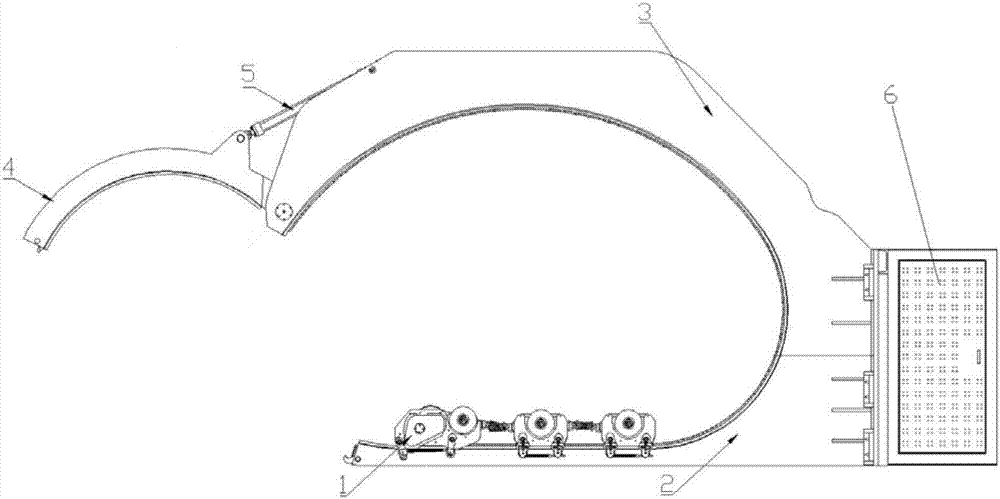

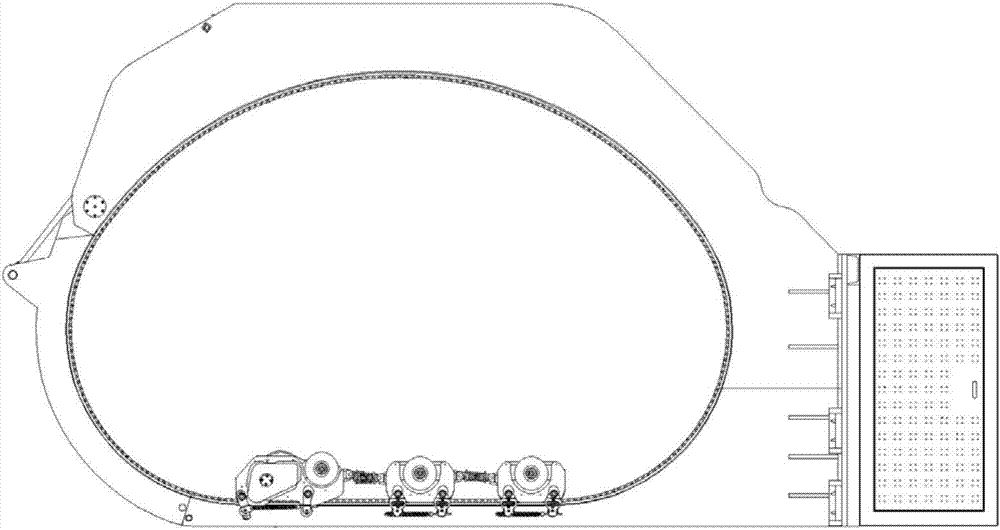

[0021] A trolley walking track device for ring-shaped object packaging, such as figure 1 , 2 Shown, comprise upper runway 3, lower runway 2 and the elephant trunk runway 4 that can be opened and closed, the elephant nose runway 4 is an arc segment, the upper end of the elephant nose runway 4 is hinged with the upper runway 3, and the elephant nose runway 4 is connected with the lower runway 2. Cooperating clips are provided at the contact end. The upper runway 3, the lower runway 2 and the elephant trunk runway 4 are closed to form a "heart"-shaped ring structure. The upper part of the elephant nose runway 4 is connected to the output end of the driving mechanism 5 and is driven by the driving mechanism 5. Control to open or close, the driving mechanism 5 is a hydraulic cylinder, installed on the upper runway 3, connected to the external control unit 6, the upper runway 3 and the lower runway 2 are fixed on the movable lifting frame, and the movable lifting frame is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com