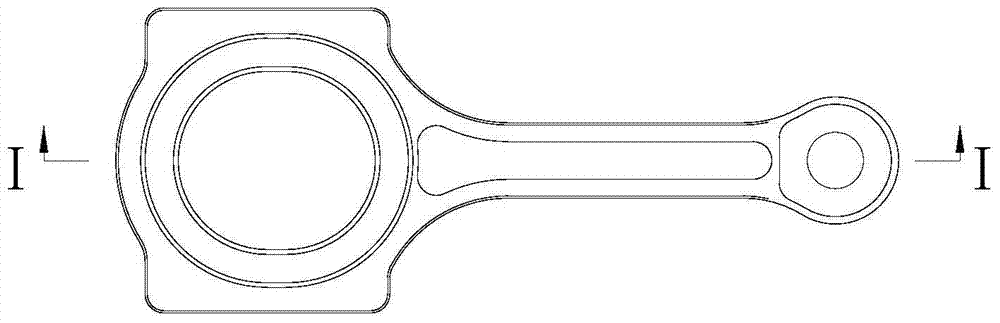

Connecting rod non-flash die forging closed die and forging process for the manufacture of key parts of automobile engines

A flash-free, die-forging technology, applied to engine components, manufacturing tools, mechanical equipment, etc., can solve the problems of forging scrap, forging flash, large residual stress, etc., achieve stable operation without impact, ensure stability, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

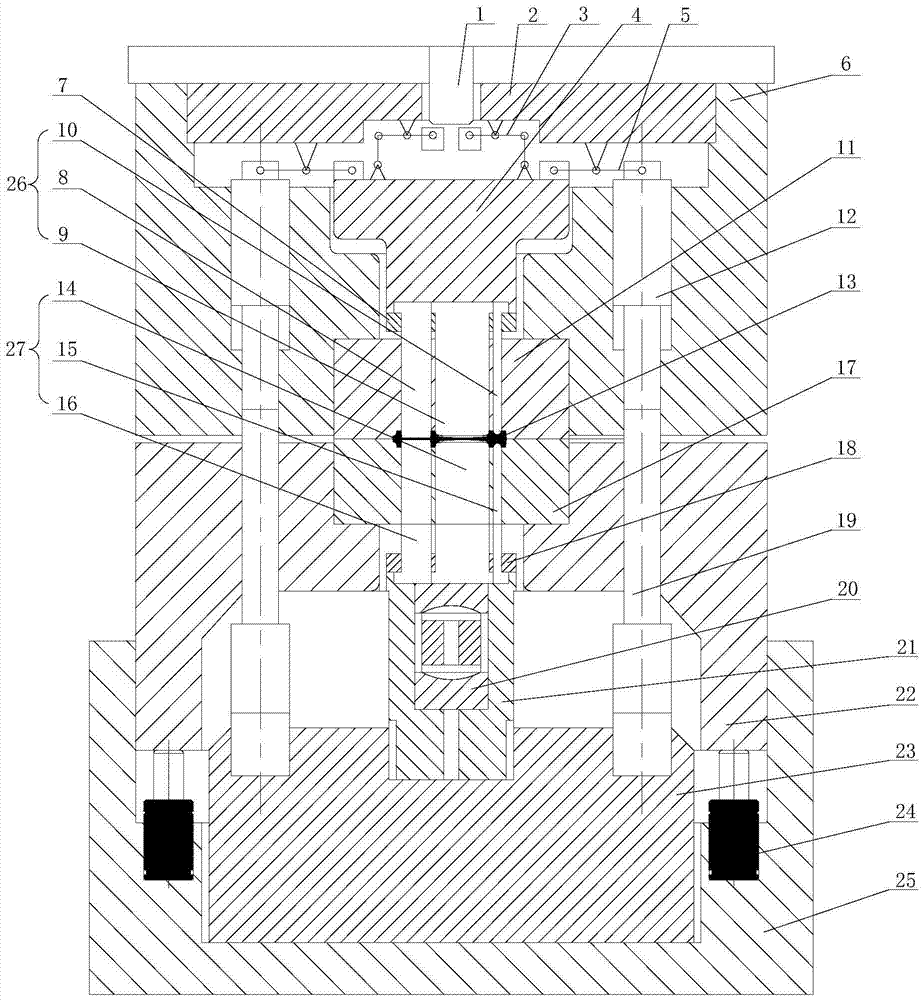

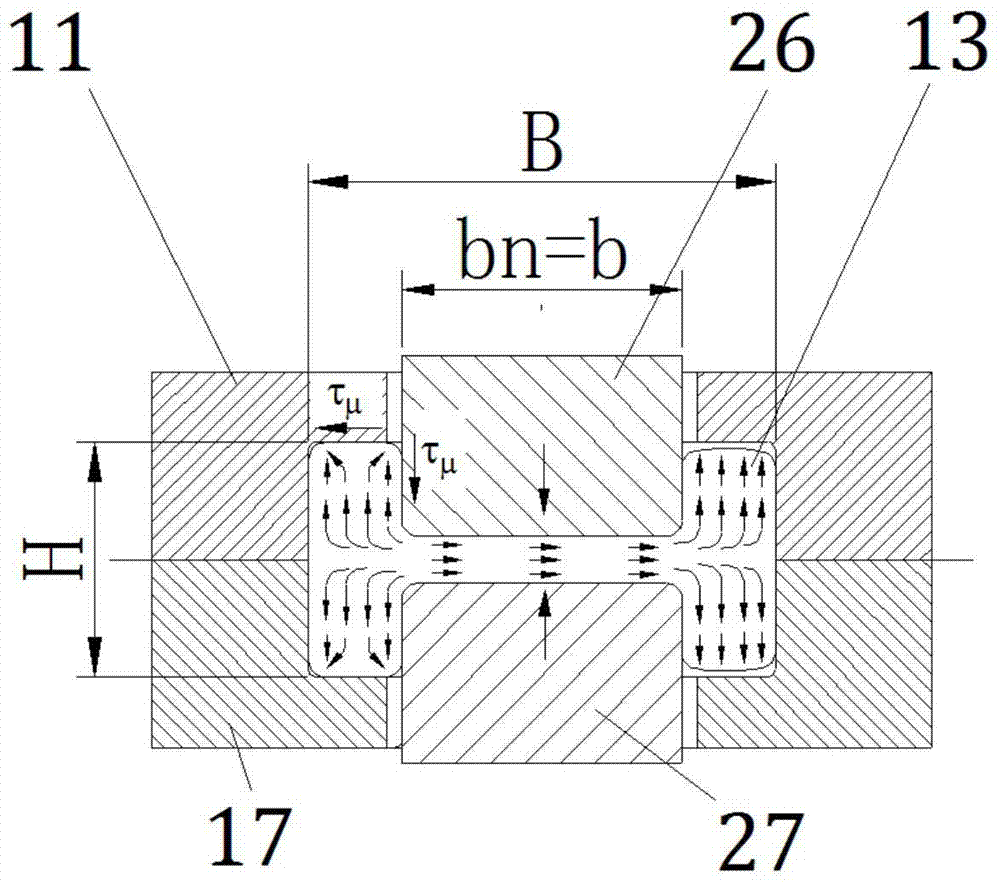

[0031] Such as figure 1 As shown, the present embodiment comprises: upper punch 26, lower punch 27, upper die 11 arranged on upper die holder 6 and lower die 17 arranged on lower die holder 22, wherein: upper punch 26 and The lower punch 27 is movably arranged in the middle part of the upper die 11 and the middle part of the lower die 17 respectively. The upper punch 26, the lower punch 27, the upper die 11 and the lower die 17 form a closed die chamber.

[0032] The lower mold base 22 is arranged in the mold frame 25 , and the two ends of the lower mold base 22 are connected to the bottom of the mold frame 25 through nitrogen springs 24 . A pivot support seat 23 is arranged in the groove in the middle of the mold frame 25 and is located between the nitrogen springs 24 at both ends. The lower mold base 22 is connected with the upper mold base 6 through the pivot 19, and the pivot 19 is arranged on both sides of the pivot support base 23, so that the lower mold base 22 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com