A tail chain tightening device for a scraper conveyor

The technology of scraper conveyor and chain tightening device is applied in the direction of conveyor, transportation and packaging, which can solve the problems of affecting work efficiency, high labor intensity of workers, and harsh underground conditions, avoiding oil leakage problems and wide practicability. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings.

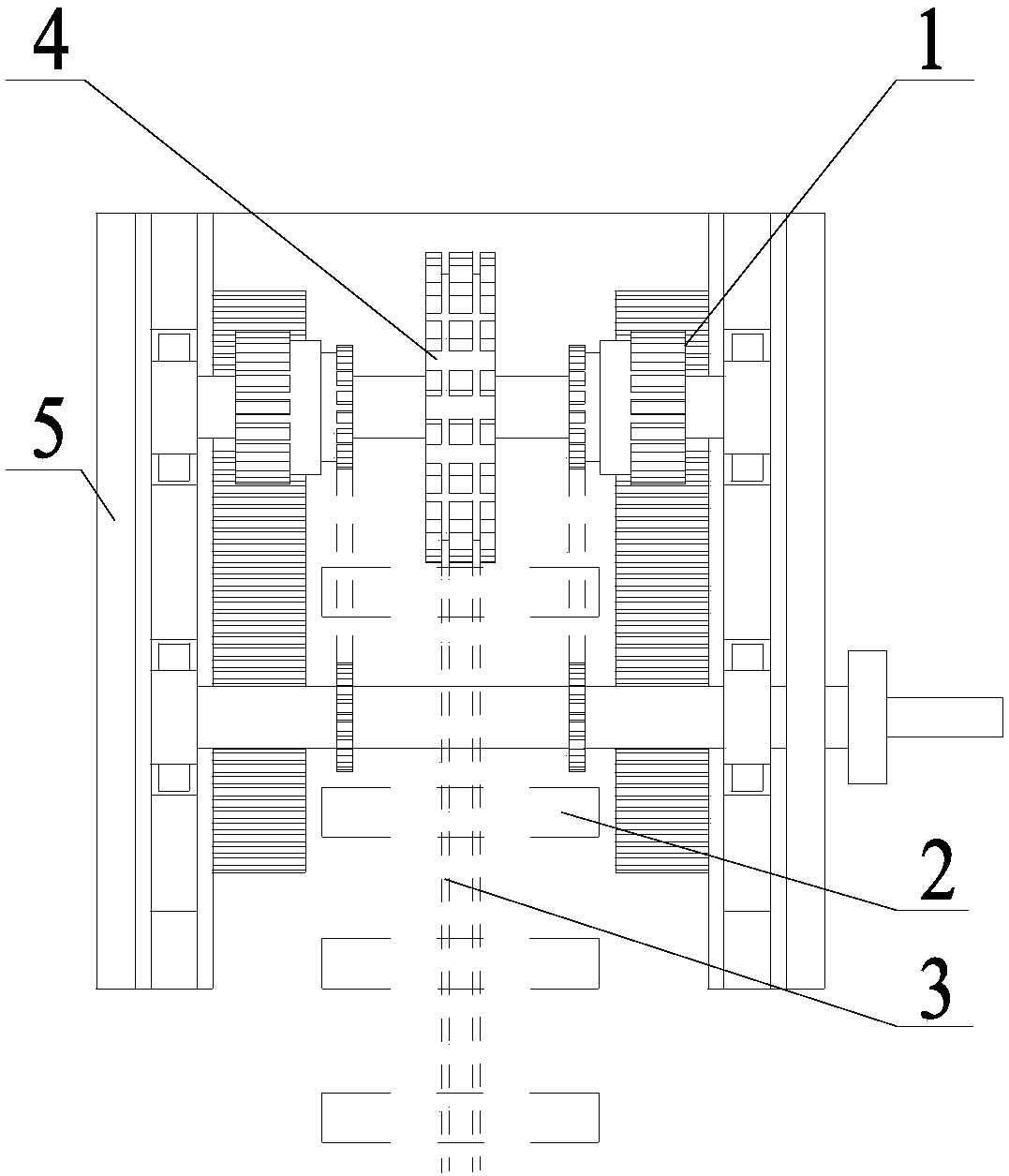

[0015] Such as figure 1 As shown, a tail chain tightening device for a scraper conveyor of the present invention, the scraper conveyor includes a steering sprocket 4, a scraper 2, a scraper chain 3, and a tail frame 5, and the scraper 2 is installed on On the scraper chain 3, the scraper chain 3 is driven by the transmission device of the machine head, the steering sprocket 4 and the scraper chain 3 are engaged at the tail of the machine and move together with the scraper chain 3, so as to realize the movement of the scraper chain 3 Turn to, and this chain tightening device 1 is installed in tailstock 5 inboards.

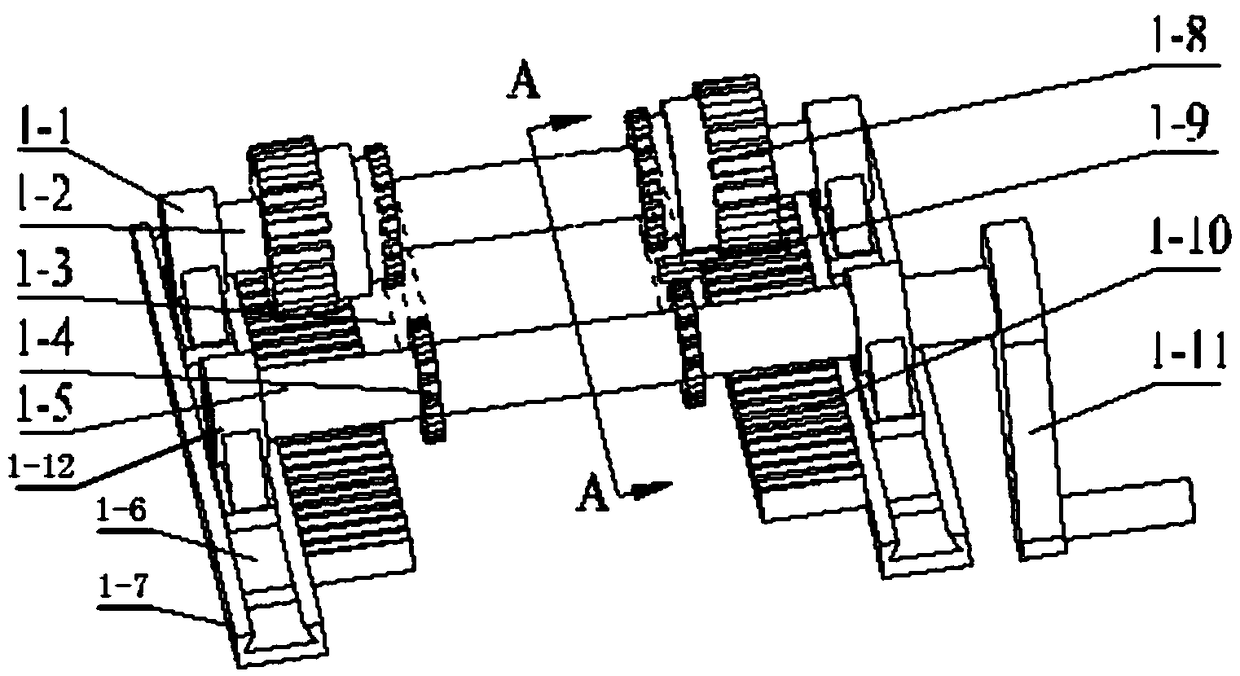

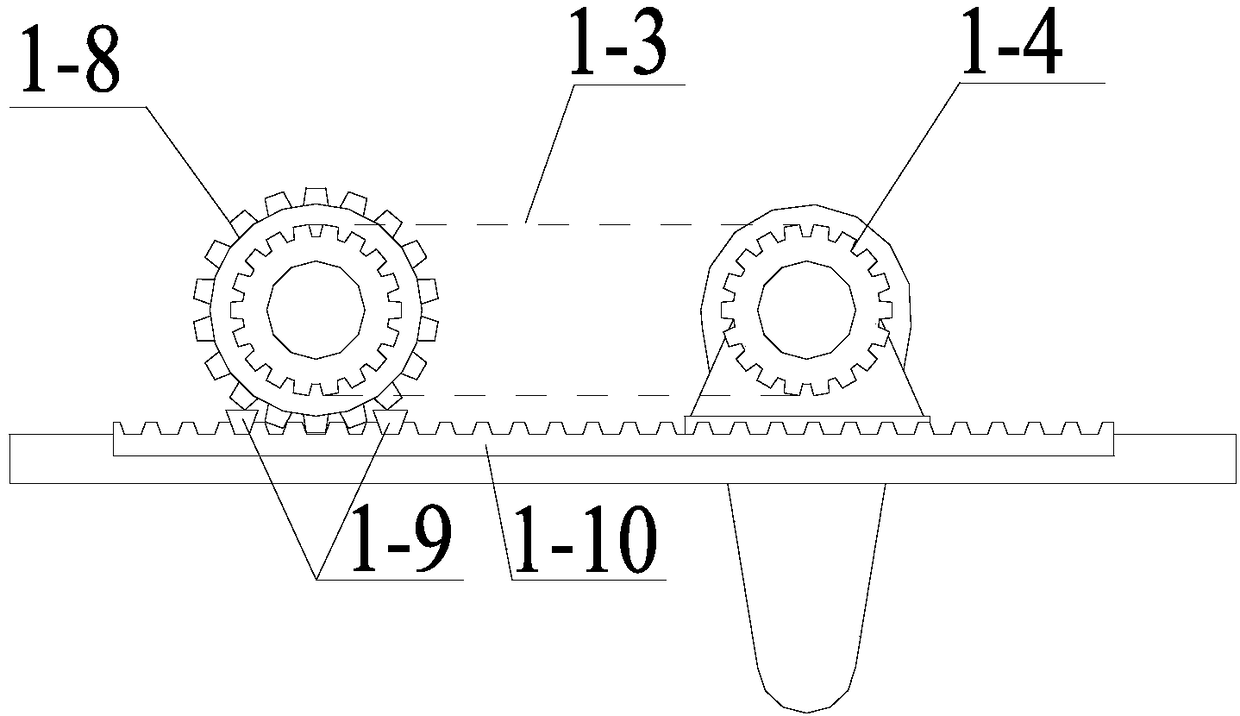

[0016] Such as Figures 1 to 4 As shown, the chain tightening device 1 includes a bearing seat A1-1, a steering sprocket shaft 1-2, a chain 1-3, an adjusting sprocket 1-4, an adjusting shaft 1-5, a slider 1-6, and a slide rail 1 -7, multifunctional wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com