Assembling method for large-megawatt wind power gear box outer-ring-free cylindrical roller bearing

A cylindrical roller bearing and wind power gearbox technology, applied in wind power generation, wind engine, transportation and packaging, etc., can solve problems such as damage to the raceway surface, and achieve easy alignment, easy control of assembly strength, and avoidance of accident risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

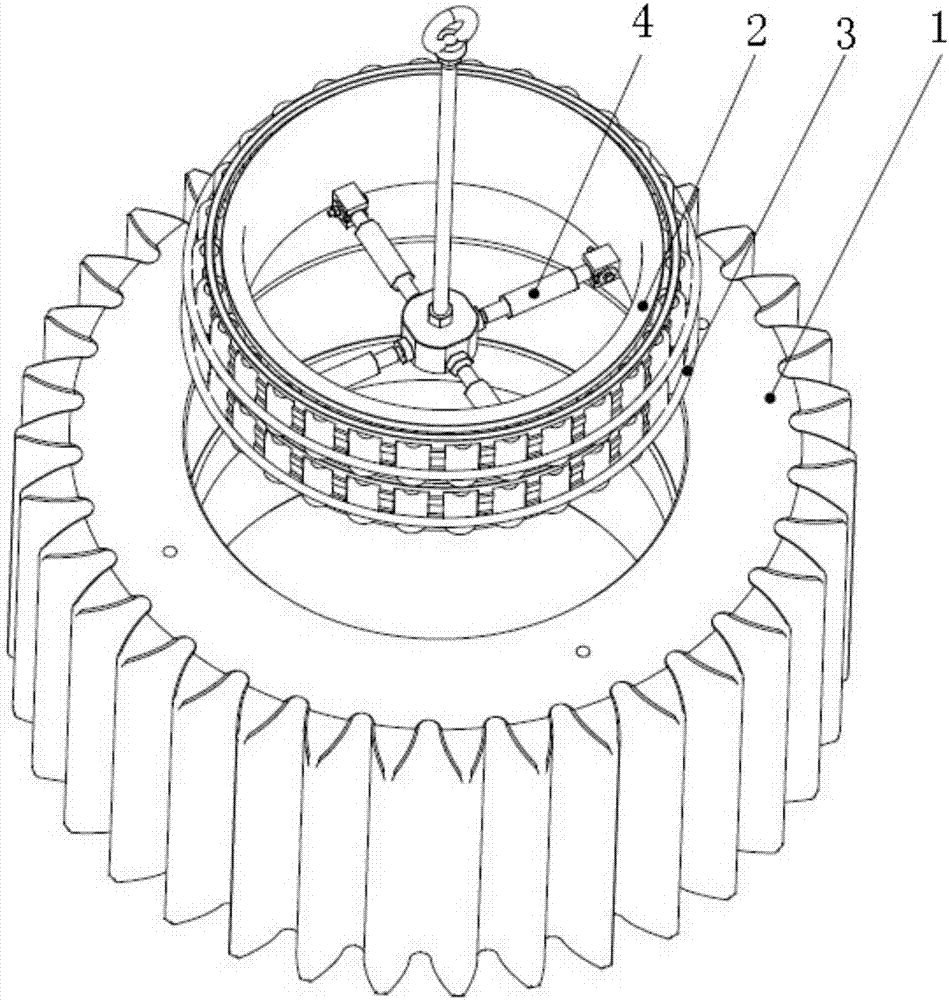

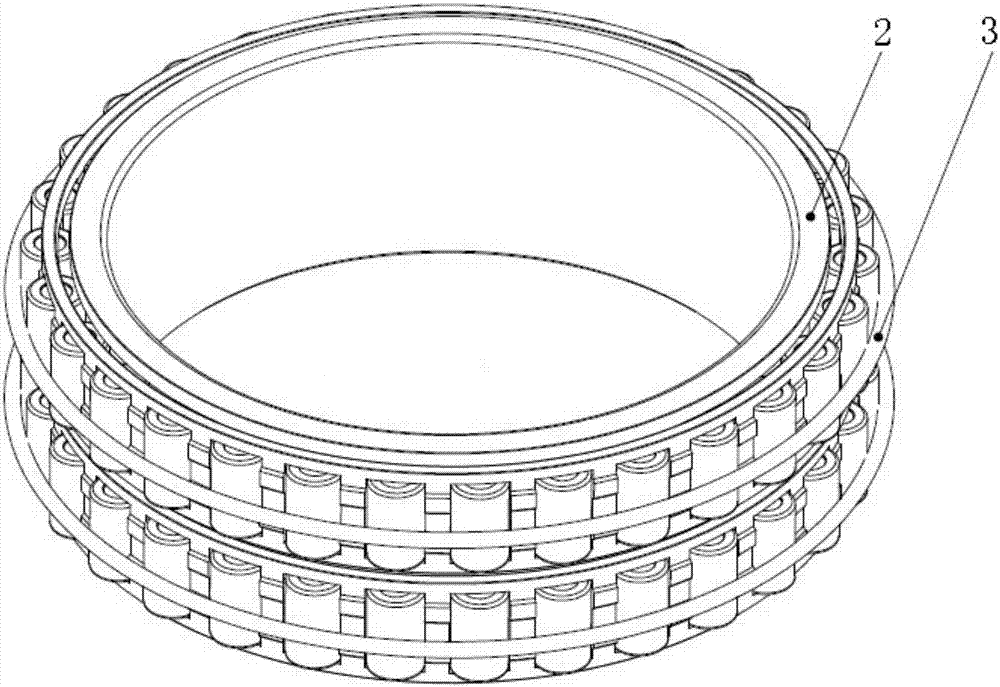

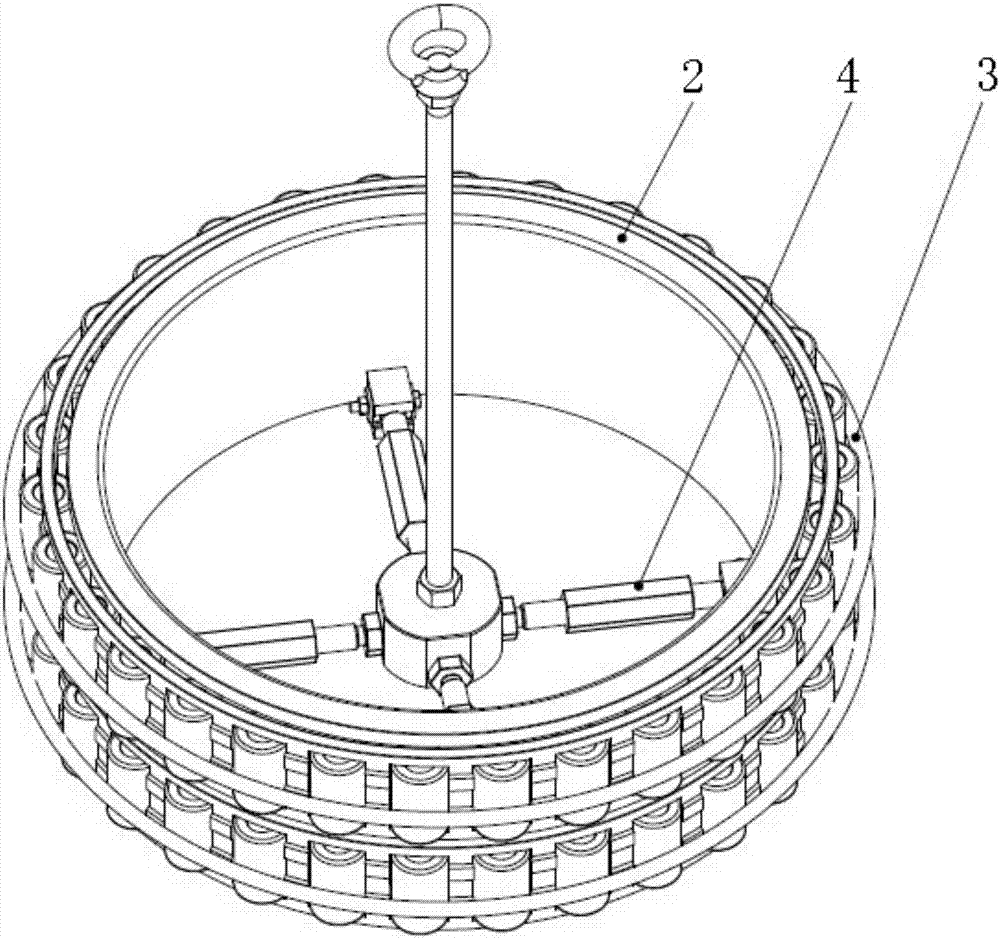

[0027] see Figure 1 to Figure 5 As shown, the assembly method of the cylindrical roller bearing without outer ring of the large megawatt wind power gearbox provided in this embodiment includes the following steps:

[0028] A. Horizontal calibration of planetary gear 1: place planetary gear 1 horizontally on a contour block, and use a spirit level to perform horizontal calibration of planetary gear 1.

[0029] B. Assembling the bearing hanger 4: Assemble the center flange 41 of the bearing hanger 4 with the ring assembly 42 and the bearing support respectively, wherein the ring assembly 41 is installed at the center of the center flange 41, and the bearing support There are four fixed-distance rows connected to the periphery of the central flange 41 through respective joints 43-1 threaded, and perpendicular to the center line of the central flange 41, each bearing support inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com