Method for preparing high-purity polyfructose

A polyfructose, high-purity technology, applied in the field of polyfructose production, can solve the problems of polyfructose polymerization degree dispersion, low purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 1kg of chicory, wash, peel, grind and crush it, then add the crushed chicory to the inulin extract, then add 10~1000U / L cellulase and 10~2000U / L pectinase to treat for 1~2h , then heat the extract to 70-90°C, stir for 1-3 hours; filter to obtain the crude inulin extract; treat the crude inulin extract through a mixture of chitosan and diatomaceous earth and a cationic macroporous resin successively, wherein , the mass ratio of chitosan and diatomaceous earth is 1-3:1, the cationic macroporous resin is LSA-40 or LX-100, and the inulin extract is obtained.

[0027] The inulin extract is processed through the first ultrafiltration membrane, the molecular weight cut-off of the first ultrafiltration membrane is greater than 3500; then the retentate is processed through the second ultrafiltration membrane, and the cut-off of the second ultrafiltration membrane is The molecular weight is 2500-3400; then the retentate is treated by nanofiltration membrane, the pore size of...

Embodiment 2

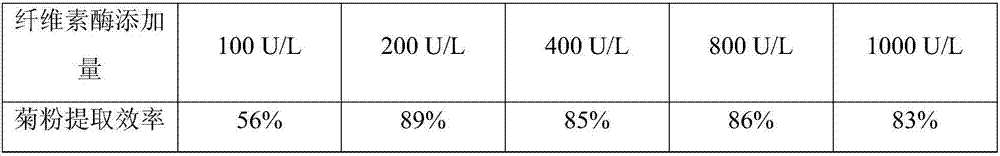

[0028] Example 2: The effect of the added amount of pectinase and cellulase on the extraction efficiency of inulin.

[0029] The operation method is the same as in Example 1, except that the addition of fixed pectinase is 500U / L, and the addition of regulated cellulase is 100U / L, 200U / L, 400U / L, 800U / L, 1000U / L ; The added amount of fixed cellulase is 800U / L, and the added amount of adjusted pectinase is 200U / L, 400U / L, 800U / L, 1200U / L, 1500U / L.

[0030] The addition amount of table 1 cellulase has the influence on the extraction efficiency of inulin

[0031]

[0032] The effect of the amount of pectinase added on the extraction efficiency of inulin in table 2

[0033] Addition of pectinase 200U / L 400U / L 800U / L 1200U / L 1500U / L Inulin Extraction Efficiency 78% 89% 92% 84% 81%

Embodiment 3

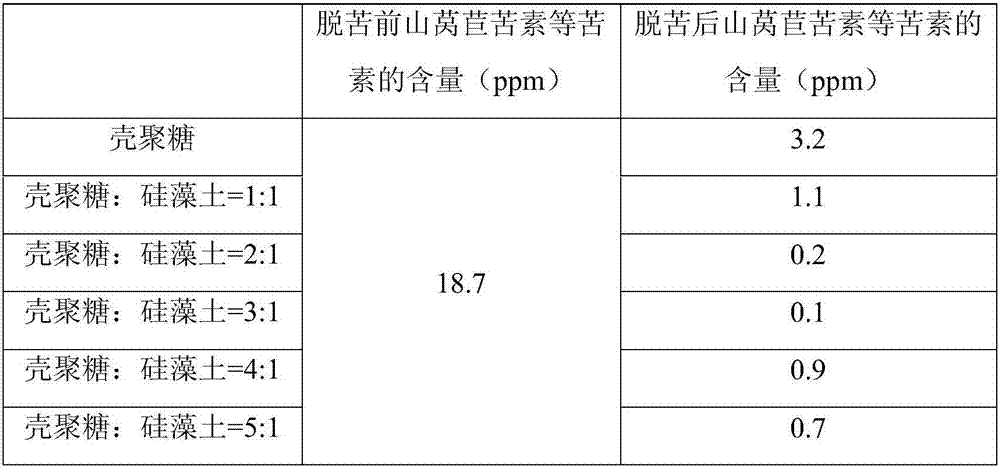

[0034] Example 3: The effect of the mixture of chitosan and diatomaceous earth on the decolorization and debittering efficiency of inulin solution.

[0035] Operation method is the same as embodiment 1, and the mass ratio of chitosan and diatomaceous earth is 1:1, the mass ratio of chitosan and diatomite is 2:1, chitosan and diatomite respectively for this inulin crude extract. The mass ratio of diatomite is 3:1, the mass ratio of chitosan and diatomite is 4:1, and the mass ratio of chitosan and diatomite is 5:1 for decolorization and debittering treatment.

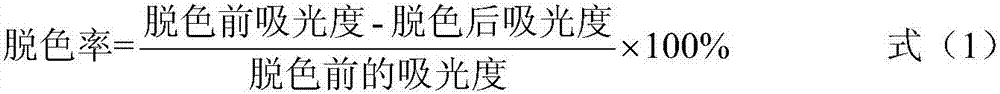

[0036] Then the decolorization effect was determined by detecting the absorbance of the fructo-oligosaccharide mixture at 560nm. The calculating method formula (1) of decolorization rate is shown in:

[0037]

[0038] The results are shown in Table 3 and Table 4.

[0039] The effect of table 3 chitosan and diatomite on the decolorization efficiency of inulin solution

[0040] Transmittance% Decolorizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com