Exhaust gas purification device for internal combustion engine

A technology of exhaust gas purification device and internal combustion engine, which is applied to exhaust gas recirculation, charging system, mechanical equipment, etc., can solve the problems of increased weight and manufacturing cost, difficulty in packaging and layout, and difficulty in realizing compactness, and achieves weight reduction. , excellent packaging and layout, improve the effect of packaging and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

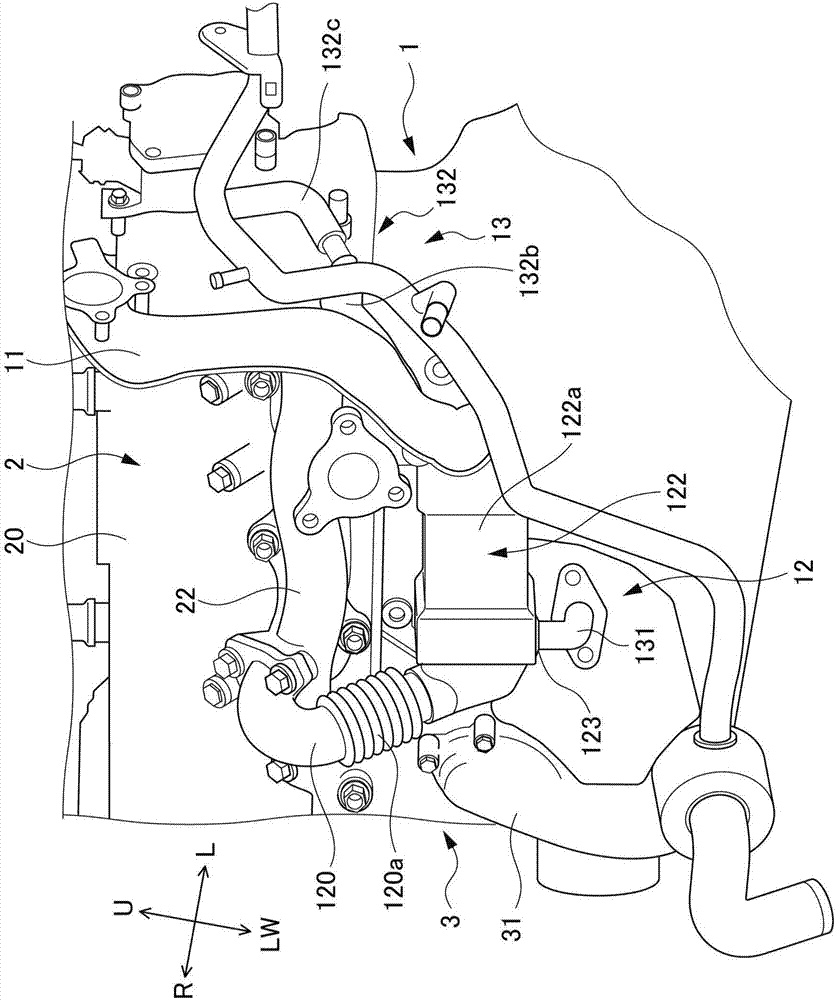

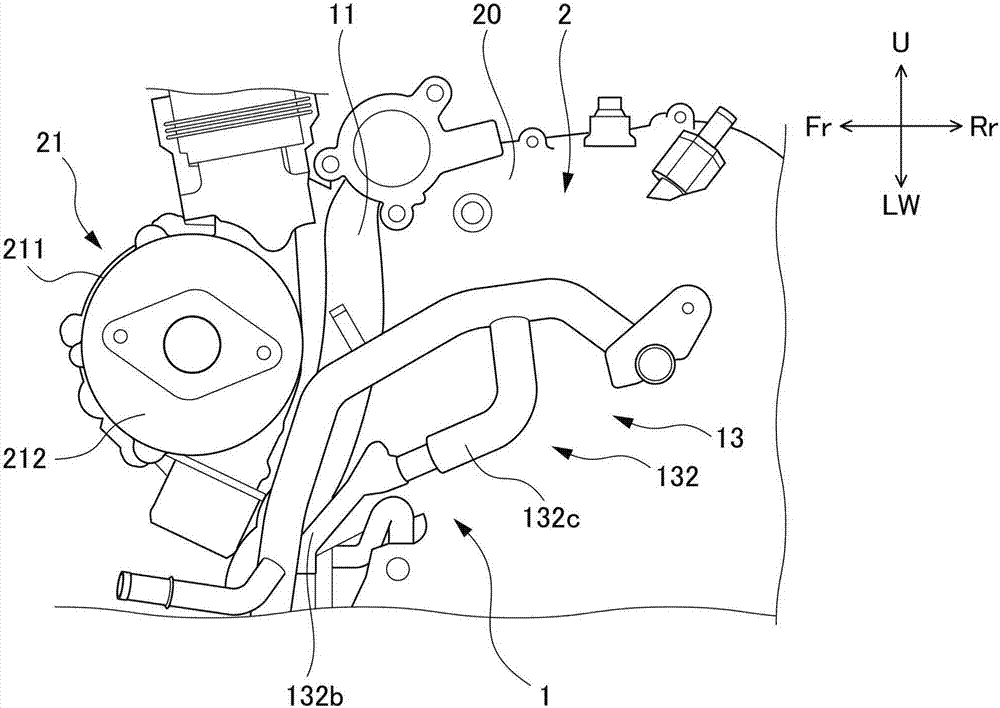

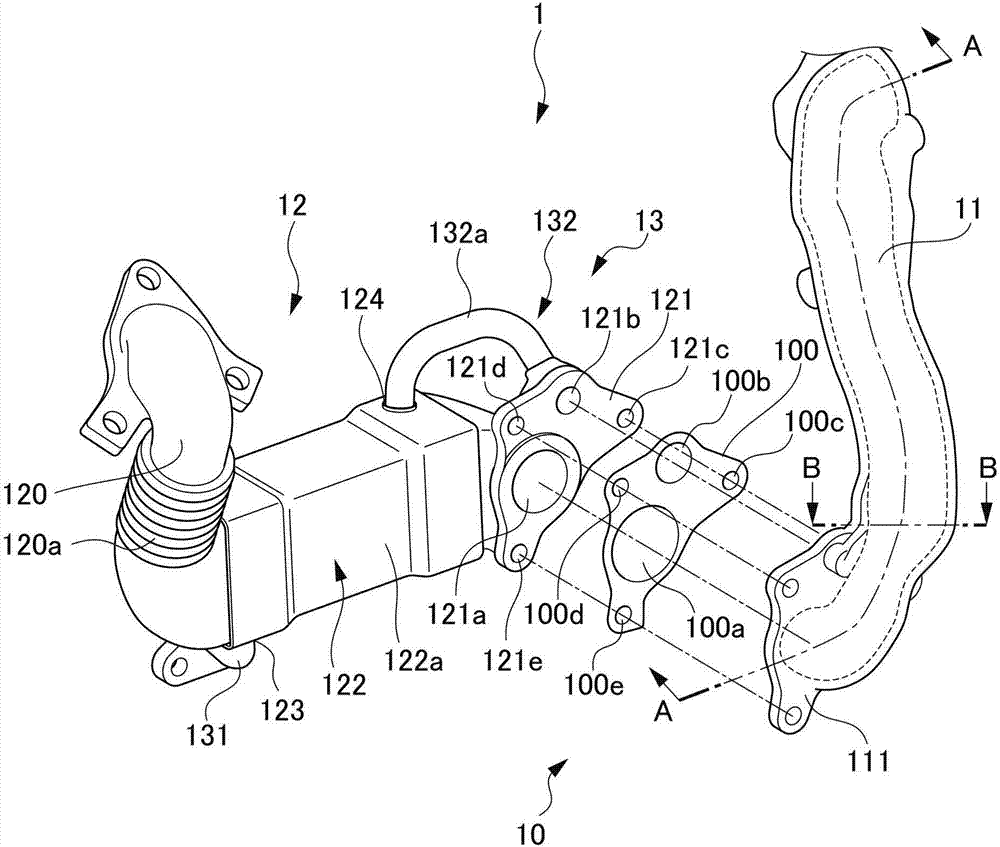

[0051] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

[0052] figure 1 It is a front view of an exhaust gas purification device 1 for an internal combustion engine according to an embodiment of the present invention. figure 2 It is a side view of the exhaust gas purification device 1 for an internal combustion engine according to the present embodiment. image 3 It is an exploded perspective view of the exhaust gas purification device 1 for an internal combustion engine according to the present embodiment. exist figure 1 and figure 2 Among them, U indicates upward, LW indicates downward, R indicates the right direction viewed from the driver, L indicates the left direction viewed from the driver, Fr indicates the front of the vehicle, and Rr indicates the rear of the vehicle.

[0053] Such as figure 1 and figure 2 As shown, the exhaust gas purification device 1 of the present embodiment is disposed on the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com