Leveling supporting leg based on planetary roller screw

A technology of planetary rollers and supporting legs, which is applied in the direction of supporting machines, engine frames, mechanical equipment, etc., can solve the problems of low reliability, difficult maintenance, slow lifting speed, etc., and achieve fast response speed, large carrying capacity, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below with reference to the drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation manners are given, but the protection scope of the present invention is not limited to the following embodiments.

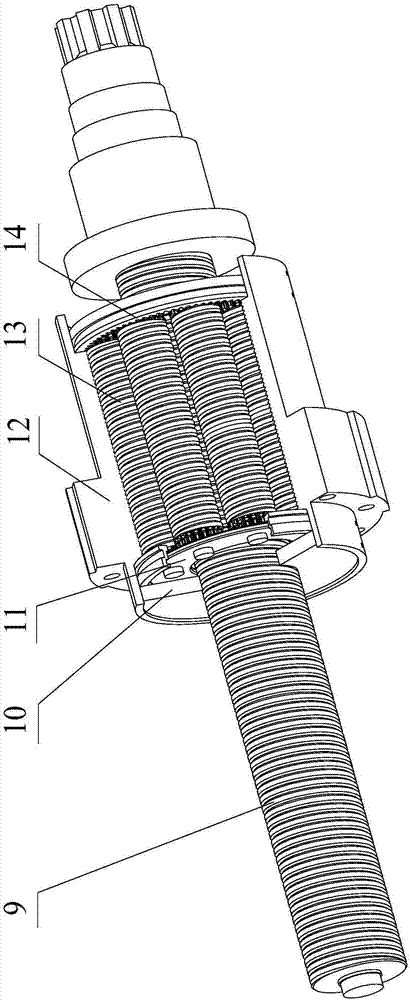

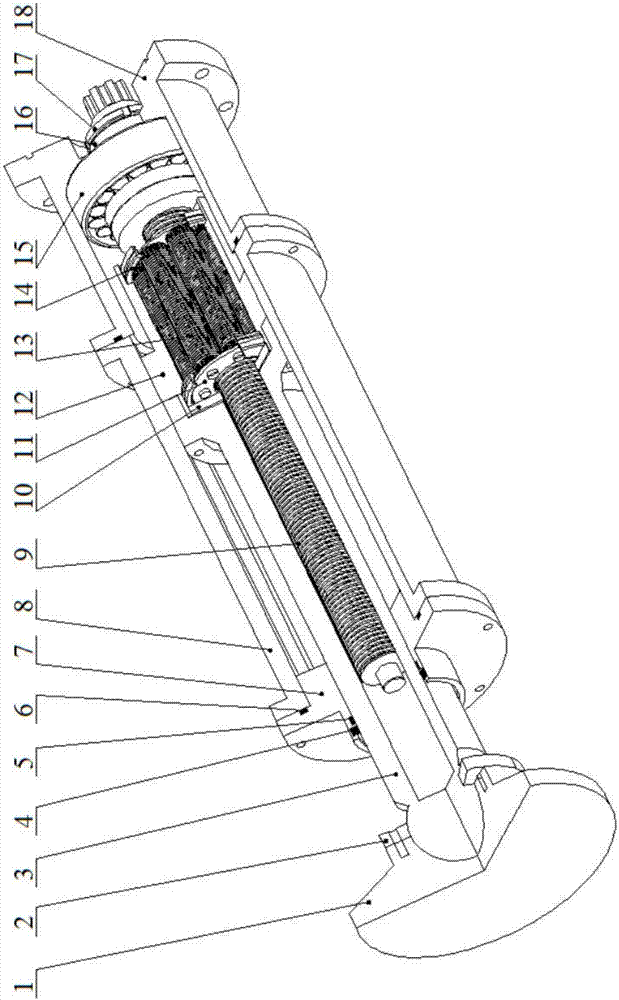

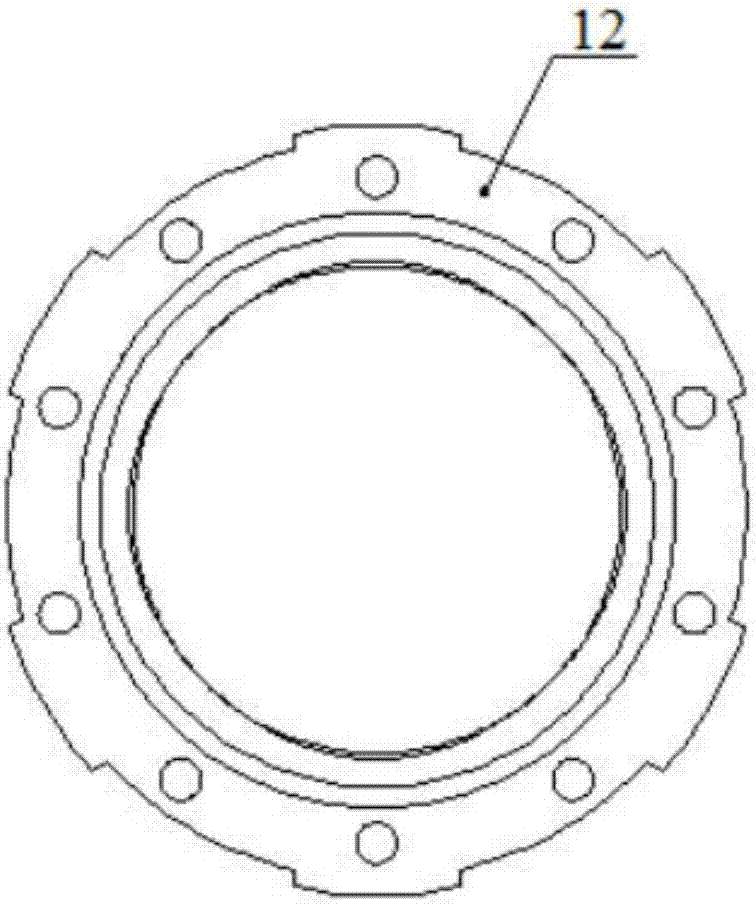

[0021] Such as Figure 1 ~ Figure 6 As shown, this embodiment is a leveling support leg mechanism based on a planetary roller screw, including: a support plate 1, a locking piece 2, a push rod 3, a J-shaped sealing ring 4, an O-shaped sealing ring 5, and an O-shaped Sealing ring two 6, head 7, guide sleeve 8, screw 9, PTFE sealing baffle 10, cage 11, nut 12, roller 13, inner gear ring 14, tapered roller bearing 1, tapered roller Bearing two 16, round nut 17, and bearing box 18, the push rod 3 and the support plate 1 are connected by a locking piece 2 to form a ball hinge; the J-shaped sealing ring 4 is combined with the O-shaped sealing ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com