Micro mirror surface warp degree detection device and detection method

A detection device and detection method technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high cost of use, low accuracy of warpage measurement, expensive optical profiler equipment, etc., and achieve the calculation method Simple, no-data-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the micromirror surface warping degree detection device and detection method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

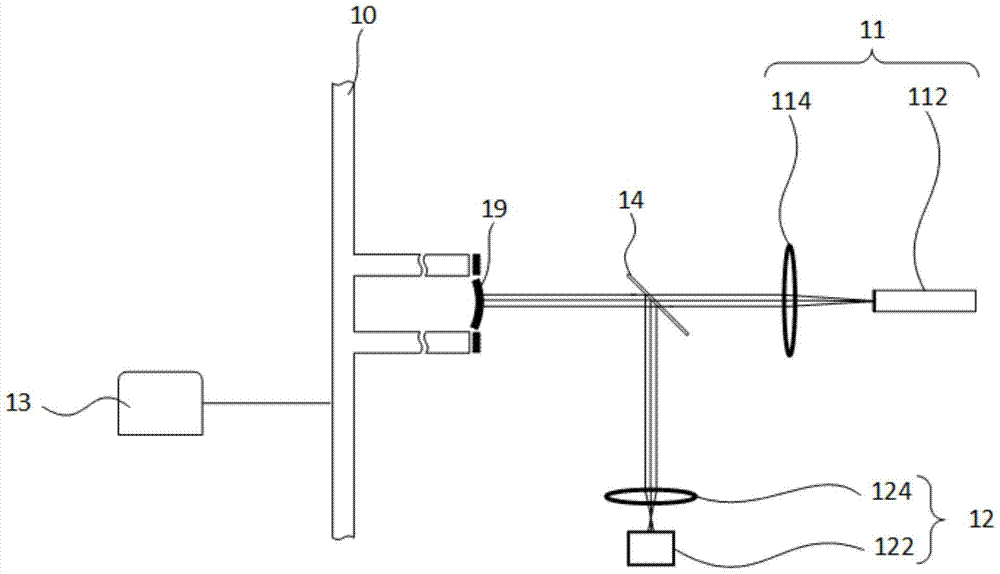

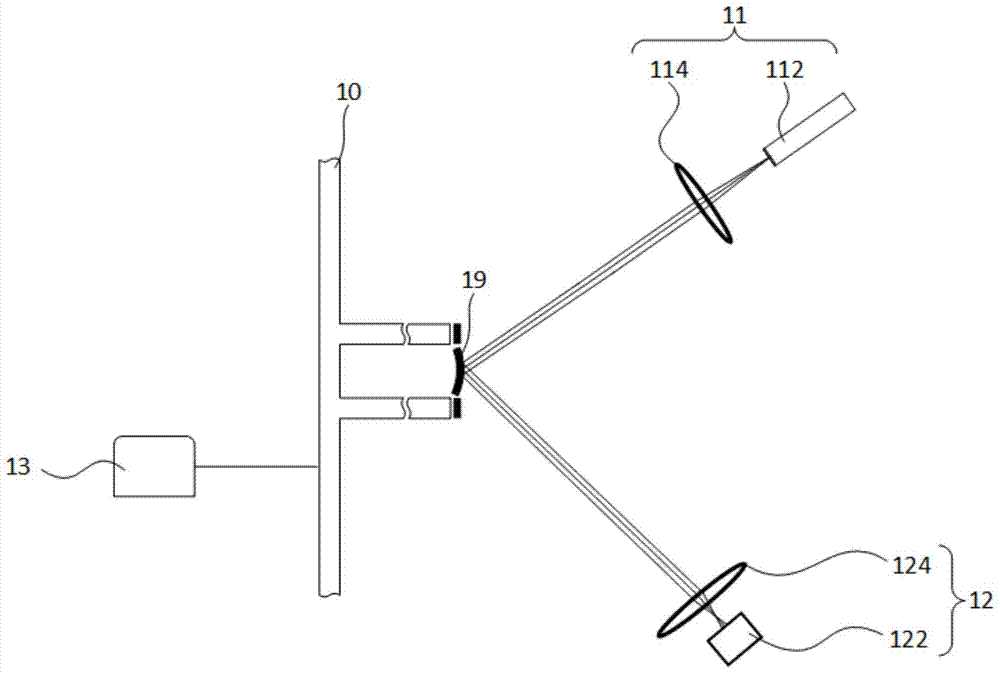

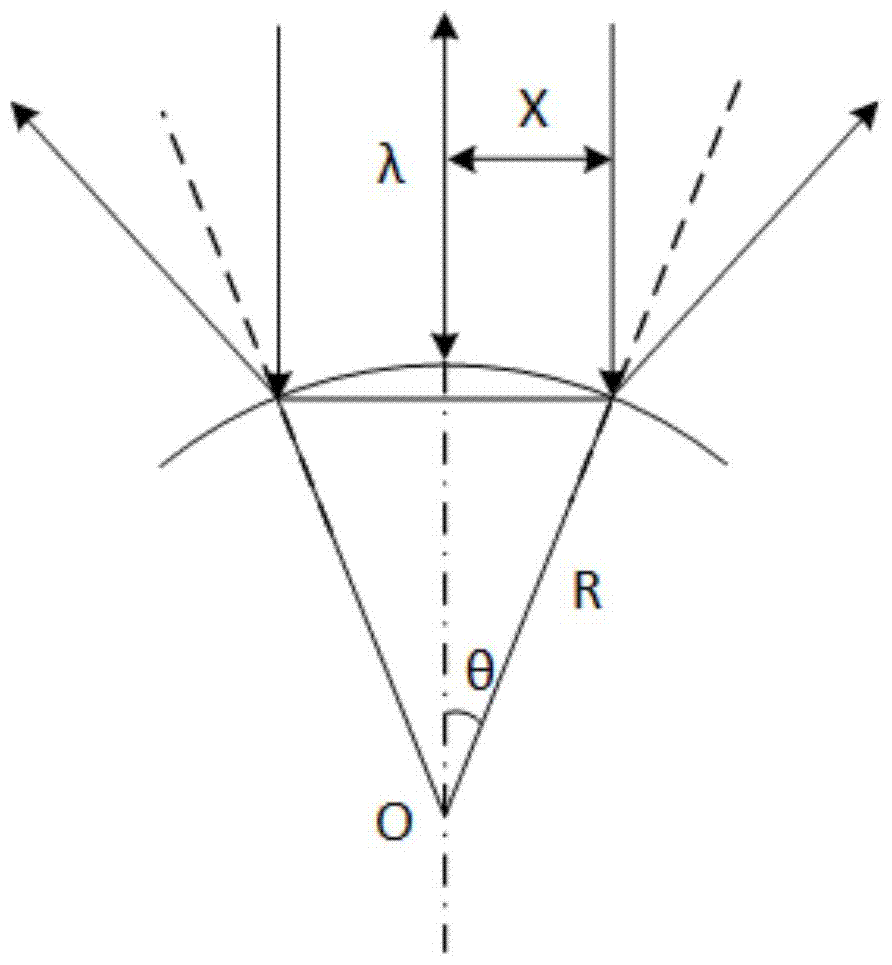

[0028] First, a specific embodiment of the micromirror surface warping degree detection device of the present invention is given in conjunction with the accompanying drawings. attached figure 1 It is a schematic structural diagram of the device described in this specific embodiment, including: a sample stage 10 , an incident light module 11 , a reflected light module 12 and a driving module 13 . attached figure 1 It is only shown as an illustration, and no measurement basis is used. In actual operation, the size of the chip sample to be tested is very small, only on the millimeter level, but the size of the chip sample table is on the centimeter level to ensure that the chip can be placed horizontally. In this specific embodiment, a wafer-level te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com