The production process of anti-fall mirror frame

A manufacturing process and frame technology, which is applied in glasses/goggles, instruments, optics, etc., can solve the problems of not fitting glasses, economic loss of people with glasses, poor consideration of anti-drop design, etc., and achieve the effect of preventing direct impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

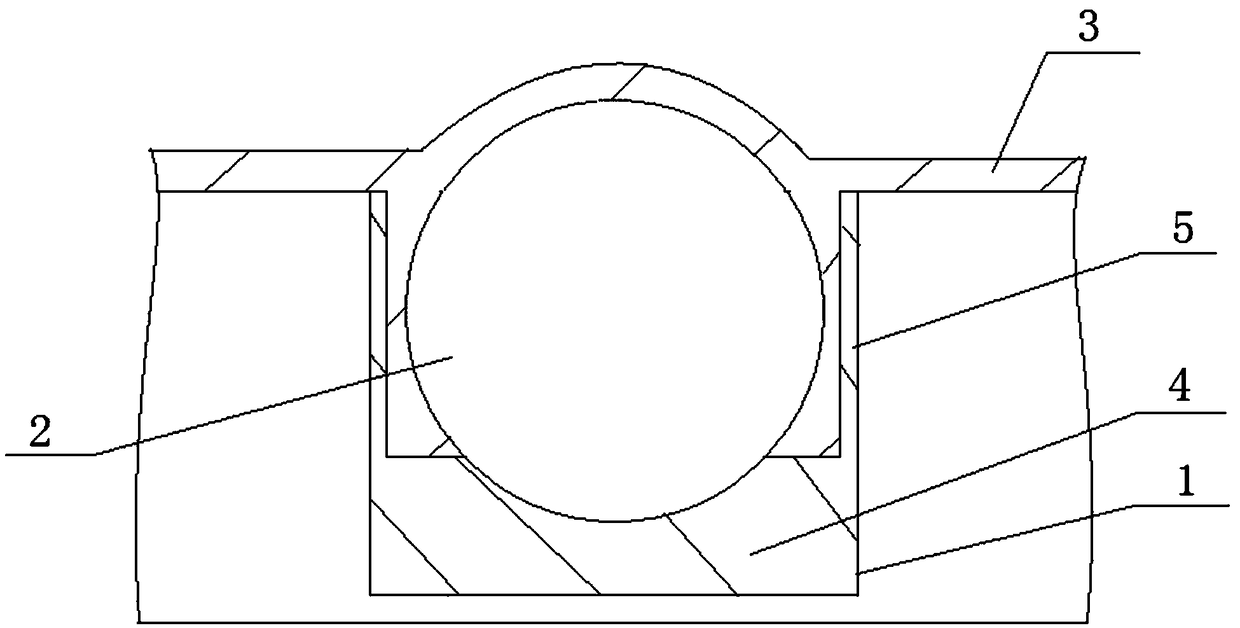

[0027] The manufacturing process of the anti-fall mirror frame, as shown in the figure, includes the following manufacturing steps:

[0028] 1) Make the steel wire into frame keel;

[0029] 2) Put the picture frame keel into the picture frame mold, and inject heated resin into the picture frame mold to form a semi-finished picture frame;

[0030] 3) Take out the semi-finished picture frame, and polish the surface of the semi-finished picture frame;

[0031] 4) Fix the polished semi-finished mirror frame by a clamp;

[0032] 5) Groove the semi-finished picture frame with a drill bit to form an anti-drop ring groove (1) with a width of 1.6mm-3mm arranged along the outer edge of the picture frame;

[0033] 6) Apply rubber in the anti-drop ring groove (1);

[0034] 7) Take several small steel balls (2) with a diameter of 1.2mm-2.5mm and put them into the anti-drop ring groove (1) and fix them with glue. The outer sides of the small steel balls (2) protrude from the edge of the ...

Embodiment 2

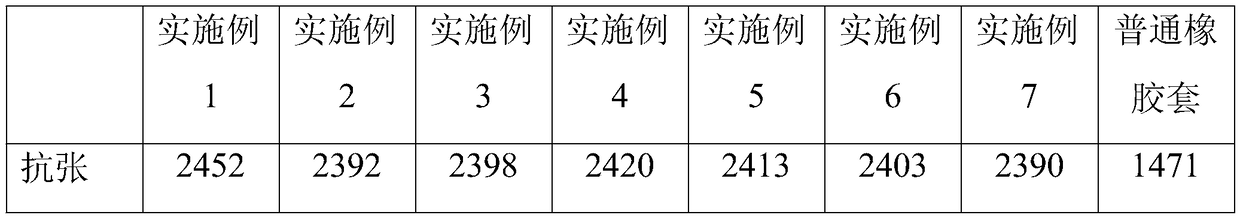

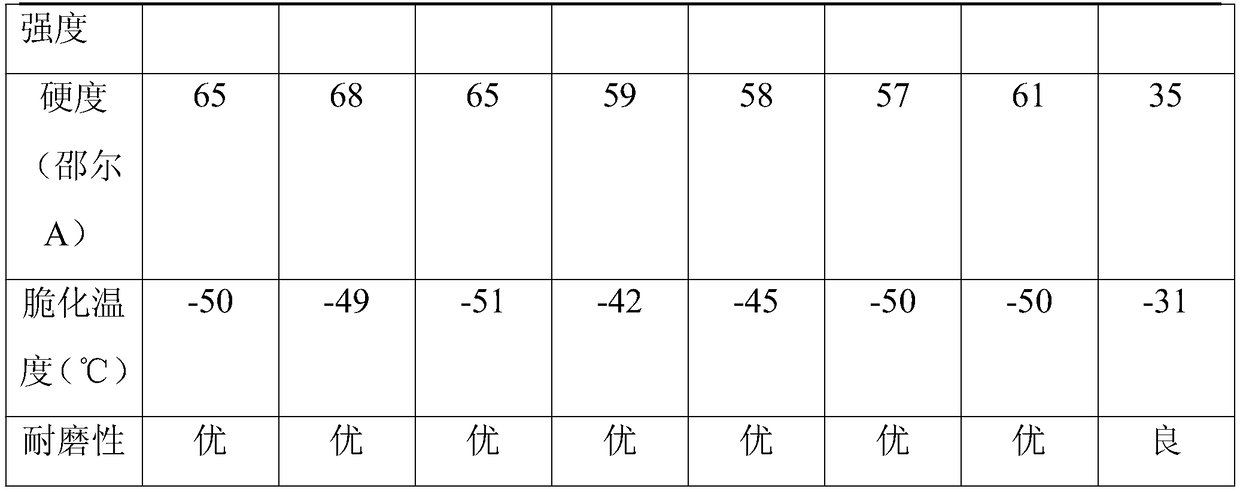

[0044] Same as Example 1, except that before step 8) taking out the finished product from the mould, the mold needs to be heated up to 170°C forming temperature, and the mixed rubber is added into the mould, and exhausted twice under a pressure of 4MPa, Hold the pressure for 65 minutes, take out the mold and place it under normal pressure, then cool the mold temperature to 10°C and keep it for 35 minutes, then gradually return to normal temperature, then rapidly heat it to 235°C and keep it for 45 seconds, and finally cool down to room temperature within 2 minutes.

Embodiment 3

[0046] Same as Example 1, the difference is that before step 8) taking out the finished product from the mould, the mold needs to be heated up to 175°C forming temperature, and the mixed rubber is added into the mould, and exhausted twice under a pressure of 6MPa, Hold the pressure for 65 minutes, take out the mold and place it under normal pressure, then cool the mold temperature to 10°C and keep it for 35 minutes, then gradually return to normal temperature, then heat it to 2235°C and keep it for 45 seconds, and finally cool down to room temperature within 2 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com