Three-phase rotating electrical machine

A rotating electrical machine, three-phase technology, applied in the field of three-phase rotating electrical machines, can solve the problem that the fractional slot structure cannot be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

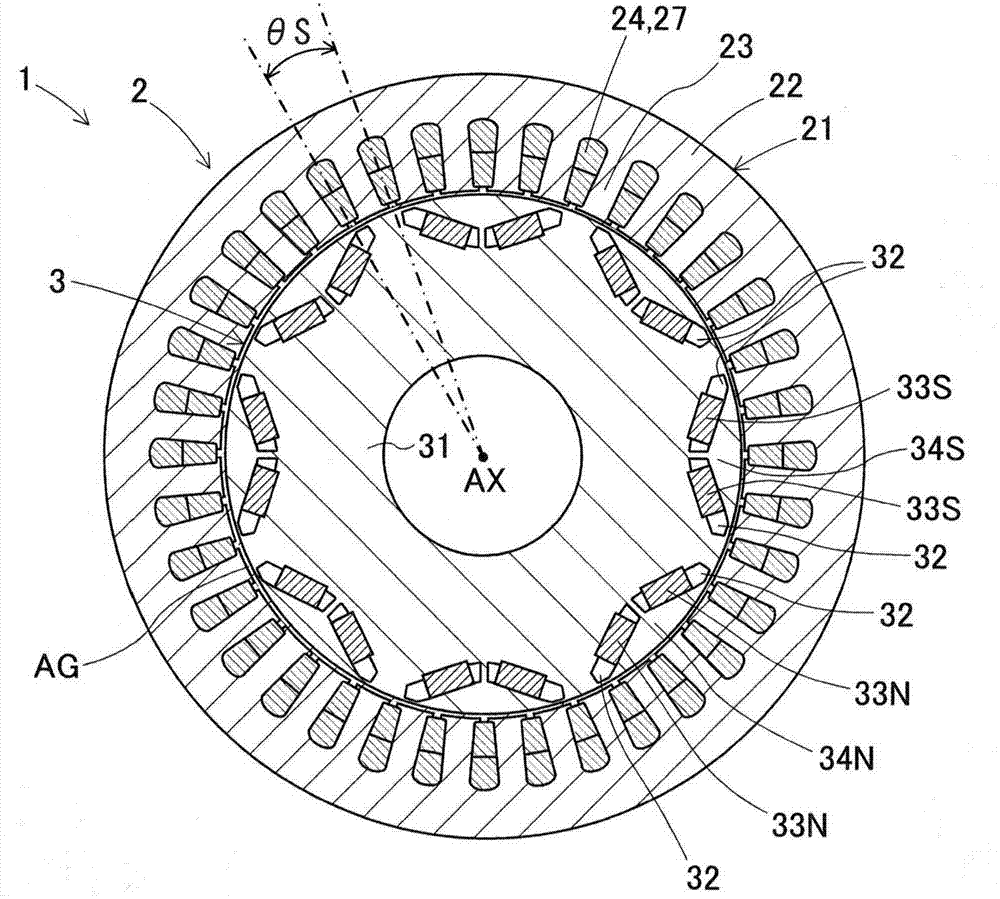

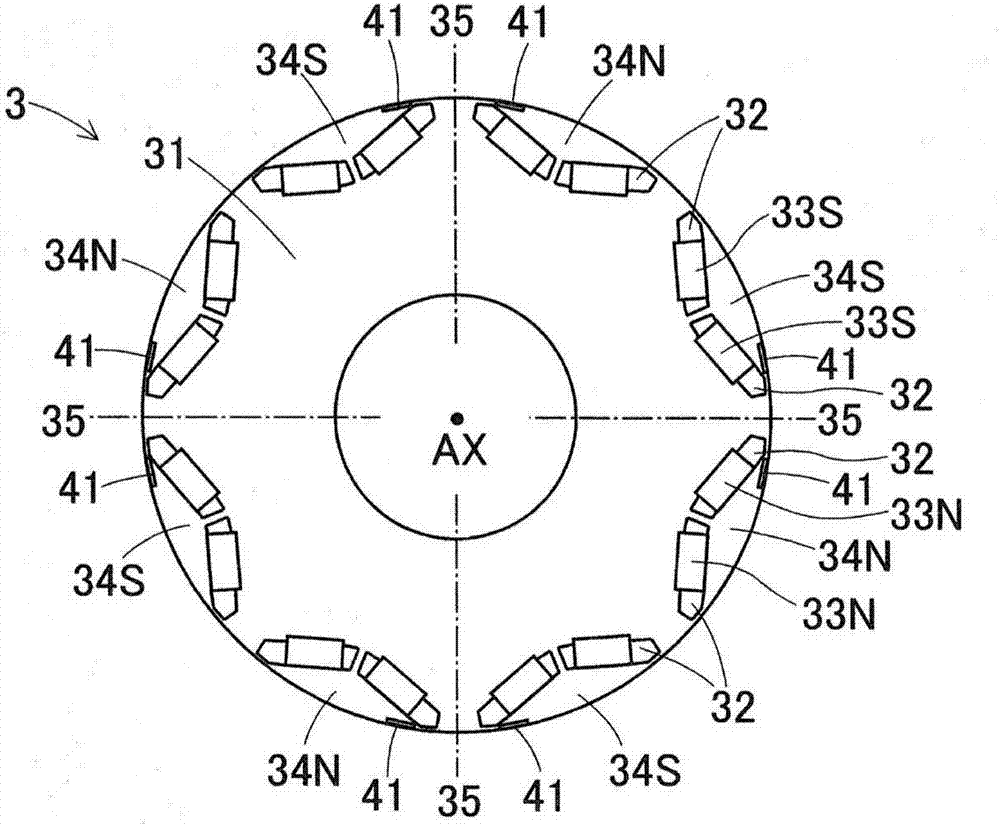

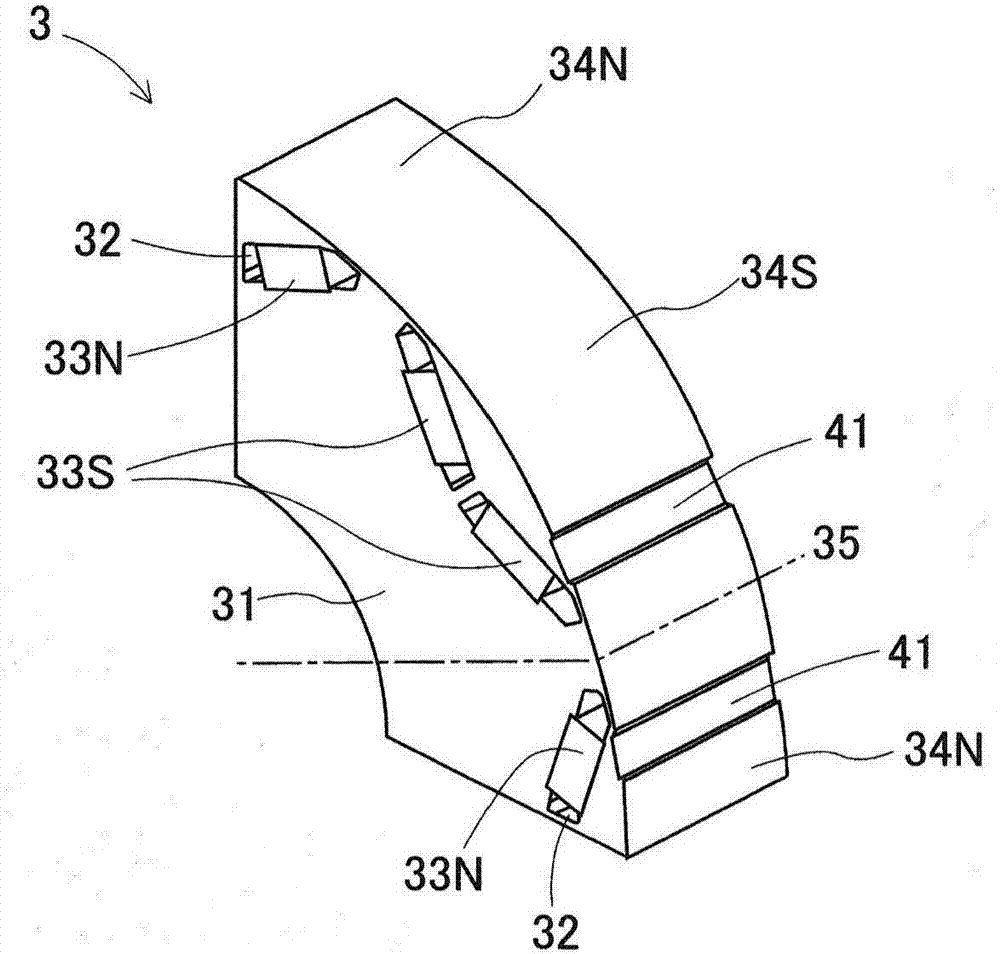

[0046] The first embodiment disclosed here and part of the second to eighth embodiments will be described. Embodiments disclosed herein relate to three-phase rotating electrical machines including a fractional slot configuration, wherein the number of slots per pole per phase is not an integer number, the number of slots per pole per phase is determined by dividing the number of slots of the stator by the poles of the movable element and further divided by 3 to obtain. will refer to figure 1 The general configuration of the three-phase rotating electrical machines 1 of the first to eighth embodiments of the present disclosure will be described. The three-phase rotating electrical machine 1 according to the first to eighth embodiments is mounted on, for example, a hybrid vehicle, and operates as a motor to drive the vehicle to run and as a generator to regenerate electric power at the time of braking. Therefore, three-phase rotating electrical machines operate over a wide ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com