Withering and dehydrating technology of tea leaves

A tea and withering technology, which is applied in tea treatment before extraction, etc., can solve the problems of limiting the enzymatic oxidation of polyphenols, the hydrolysis and release of aroma precursors, shortening the time of withering and fermentation, and the negative impact on black tea quality. The effect of withering time, bright tea soup, and speeding up production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

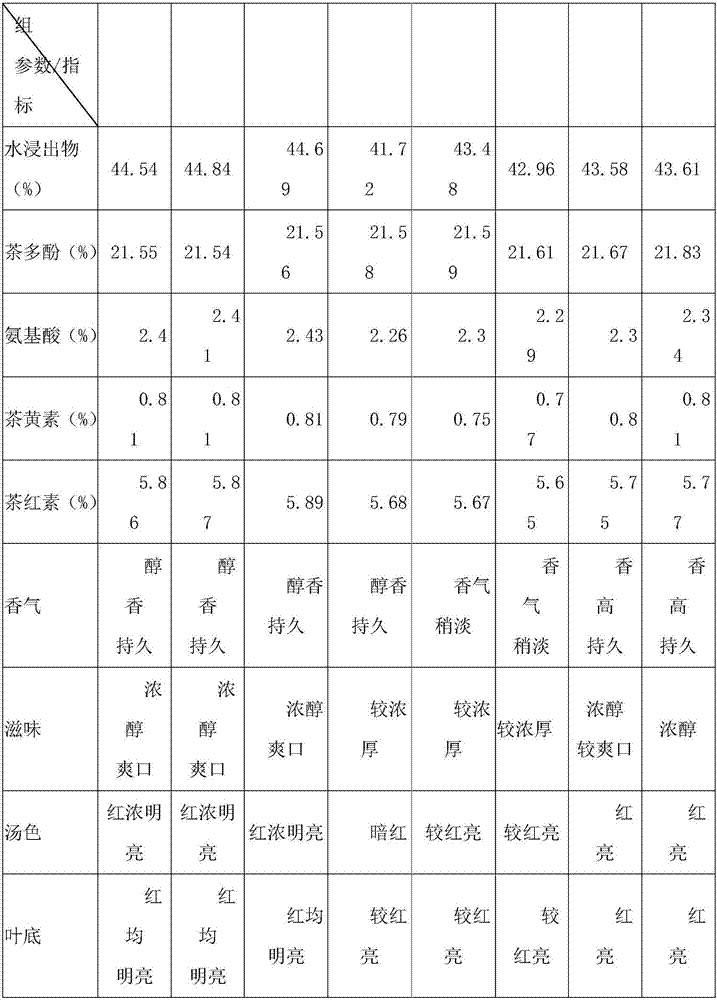

Examples

Embodiment 1

[0022] This embodiment discloses a process for withering and dehydrating tea leaves, comprising the following steps:

[0023] (1) Pretreatment: Use hot air at 43-48°C to blow the fresh leaves after picking for 40-48 minutes, and shake the tea leaves continuously during the blowing process to cause friction between tea leaves and tea leaves, tea leaves and machinery;

[0024] (2) Prepare almonds, grind almonds to 70-80 mesh, and then use supercritical co2 fluid extraction process to extract extract 1; during this process, control the extraction pressure at 28-30mpa, temperature 50-53°C, time 75-85min, CO2 flow 12-14SLH;

[0025] (3) Pressurization: fully mix the tea leaves obtained in step (1) with the extract 1, and then carry out vacuum packaging to a vacuum degree of 0.8-1.0MPa; place the vacuum packaging in a high-pressure container, apply a pressure of 180-240MPa, and keep 10-12min;

[0026] (4) Place the tealeaves obtained in step (3) on the withering frame and wither f...

Embodiment 2

[0029] The difference between Example 2 and Example 1 is that a pre-step is added before the pretreatment, the tea leaves are evenly spread on the bamboo plaque, and the light with a wavelength of 650-980nm and an illumination intensity of 15000-18000lx is used for 25-30min.

Embodiment 3

[0031] The difference between embodiment 3 and embodiment 1 is: (1) pretreatment: utilize the hot wind of 43-48 ℃ to blow altogether 40-48min to the fresh leaves after picking, constantly shake tealeaves in the process of blowing, make tealeaves and tealeaves, tealeaves There is friction with the machine; stop blowing hot air and shake for 3 minutes every 9 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com