Monocrystalline silicon piece washing device

A technology for single crystal silicon wafers and cleaning devices, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., capable of solving the problems of residual stains on the surface of single crystal silicon wafers, poor cleaning quality, and cleaning Time-consuming and labor-intensive problems, to achieve the effect of saving time and labor, high degree of cleaning automation, and high cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

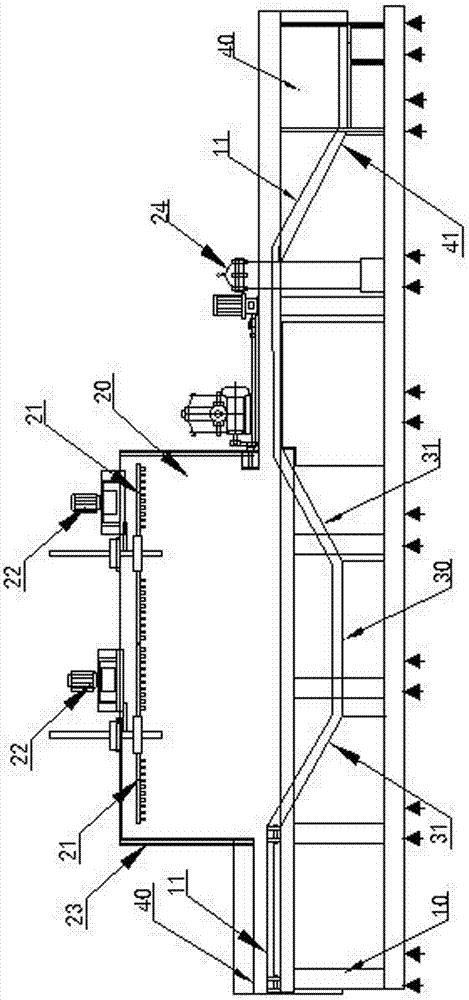

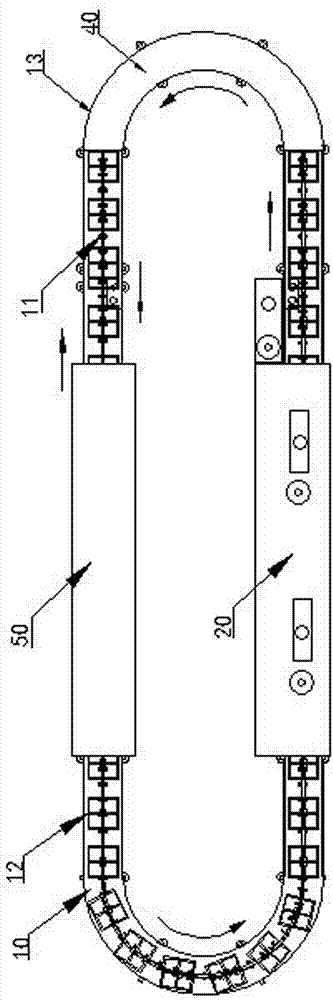

[0016] figure 1 , figure 2 In the shown embodiment, a single crystal silicon wafer cleaning device includes a cleaning tank and an annular cleaning frame. A conveying track 11 is installed on the annular cleaning frame 10, and a plurality of single crystal wafers are installed on the conveying track. The silicon wafer conveying bracket 12, the conveying track 11 includes a conveying straight path, a conveying ramp connected to the conveying straight path, and an annular conveying path at both ends of the ring-shaped cleaning rack, and a cleaning chamber 20 is installed on the straight section of the ring-shaped cleaning rack. , the ring-shaped cleaning rack is provided with a drying chamber 50 at another straight line section, and a plurality of inclined sinking cleaning tanks 30 are installed in the cleaning chamber, and the conveying track 11 is transported through the cleaning chamber 20, and in the tank in the inclined sinking cleaning tank 30 The conveying track has a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com