Precision control method for cargo hold broadside segmentation carrying of multipurpose ship

A precision control and multi-purpose technology, applied to ship components, ship construction, ships, etc., can solve the problems of manpower and material resources, impact of shipbuilding and dock cycle, levelling, marking inconvenience, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

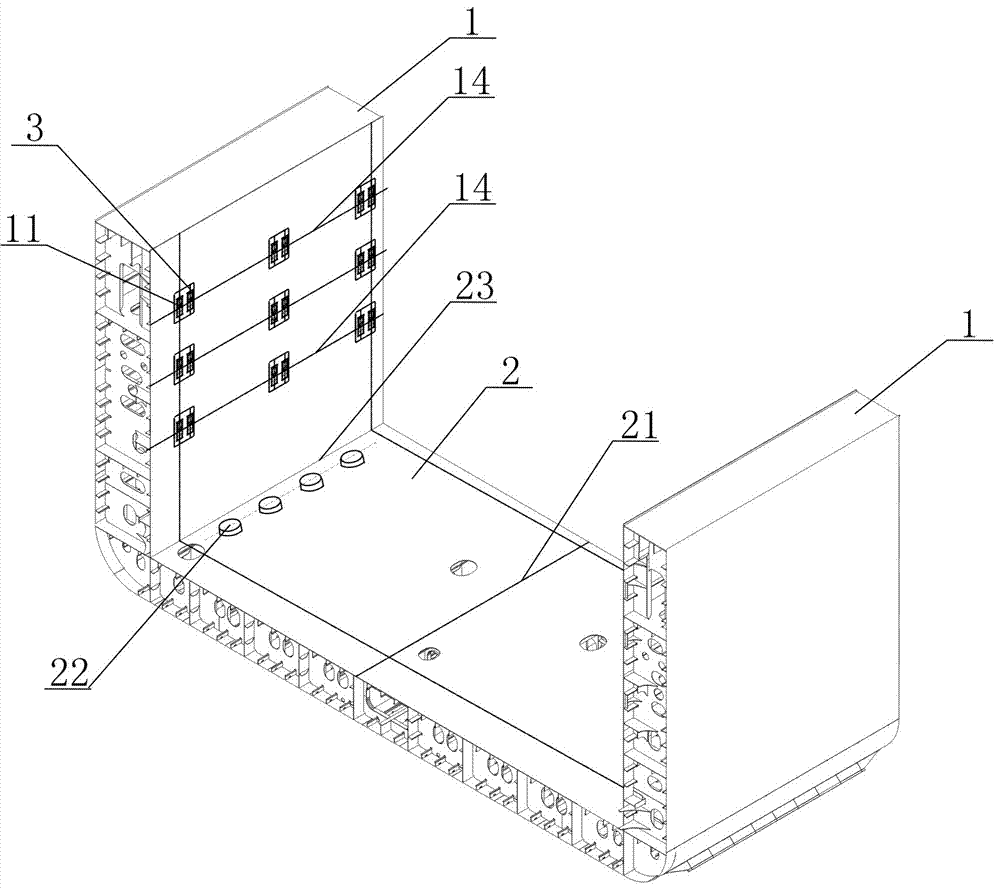

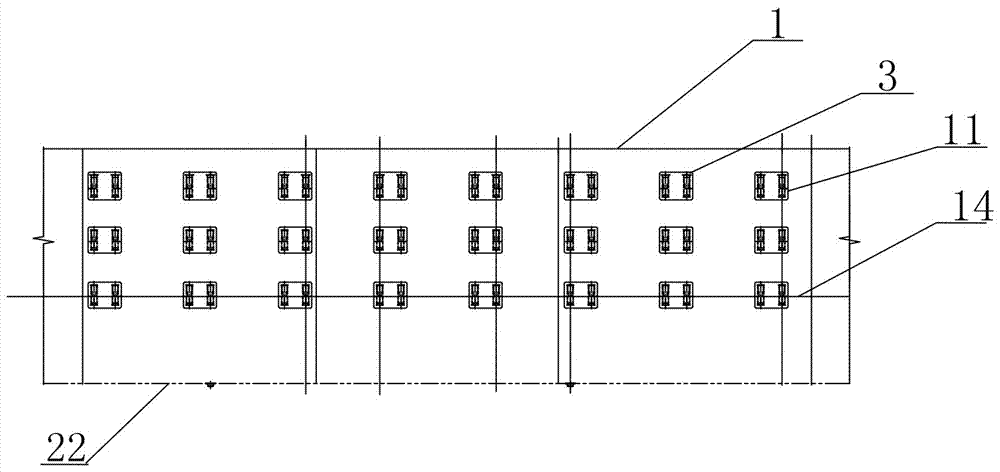

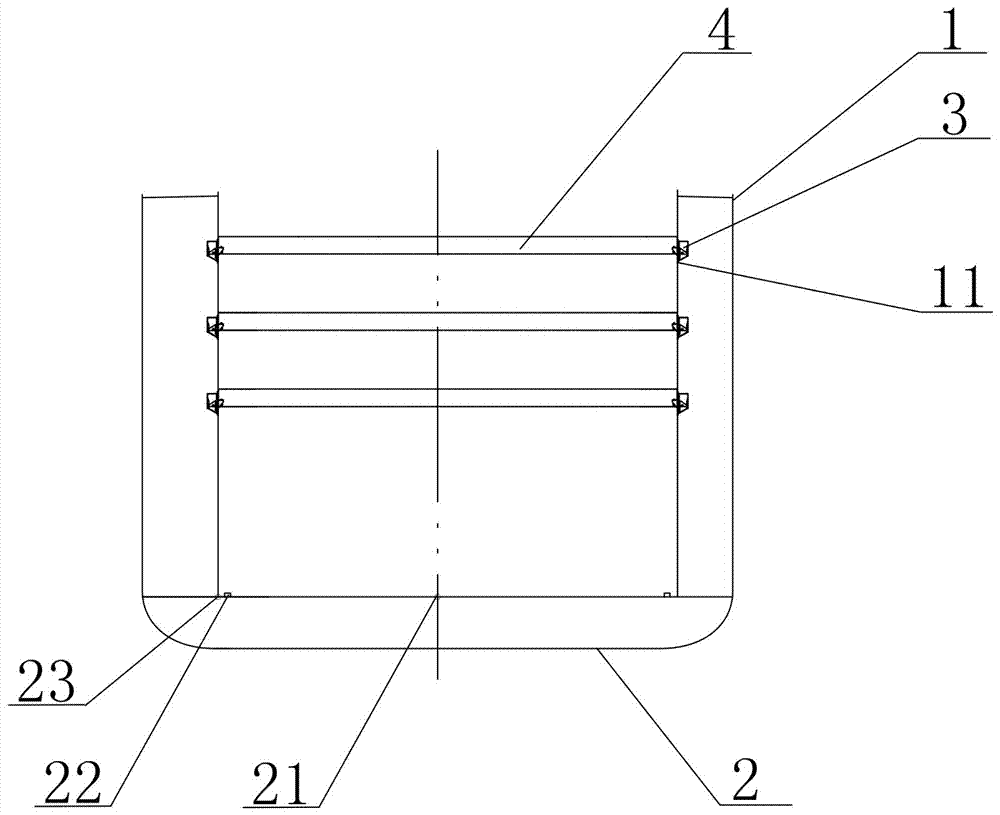

[0022] a), the side of the production: refer to figure 1 , figure 2 , according to the design requirements, complete the production of the side 1 of the multi-purpose ship cargo hold in sections, and set installation marks for each section of the side 1;

[0023] b) Set side datum: refer to figure 1 , figure 2 , set the side contour datum line 14 on the side side 1, and draw a plurality of support box installation hole lines according to the side contour datum line 14;

[0024] c), Open the installation hole of the support box: refer to figure 1 , figure 2 , according to the installation hole line of the support box on the side 1, carry out drilling and trimming, complete the installation hole 11 of the support box, and test the shape and position accuracy of the installation hole 11 of the support box as required until it is qualified;

[0025] d), Install the support box: refer to figure 1 , figure 2 , installing the finished support box 3 into the support box ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com