Automobile coating anolyte circulation protection system

A protection system and anolyte technology, applied in coatings, electrolytic coatings, electrophoretic plating, etc., can solve the problems of wasteful production costs, inability to ensure normal production, and the inability of the anode system to alarm and remind in time, and achieve the effect of reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

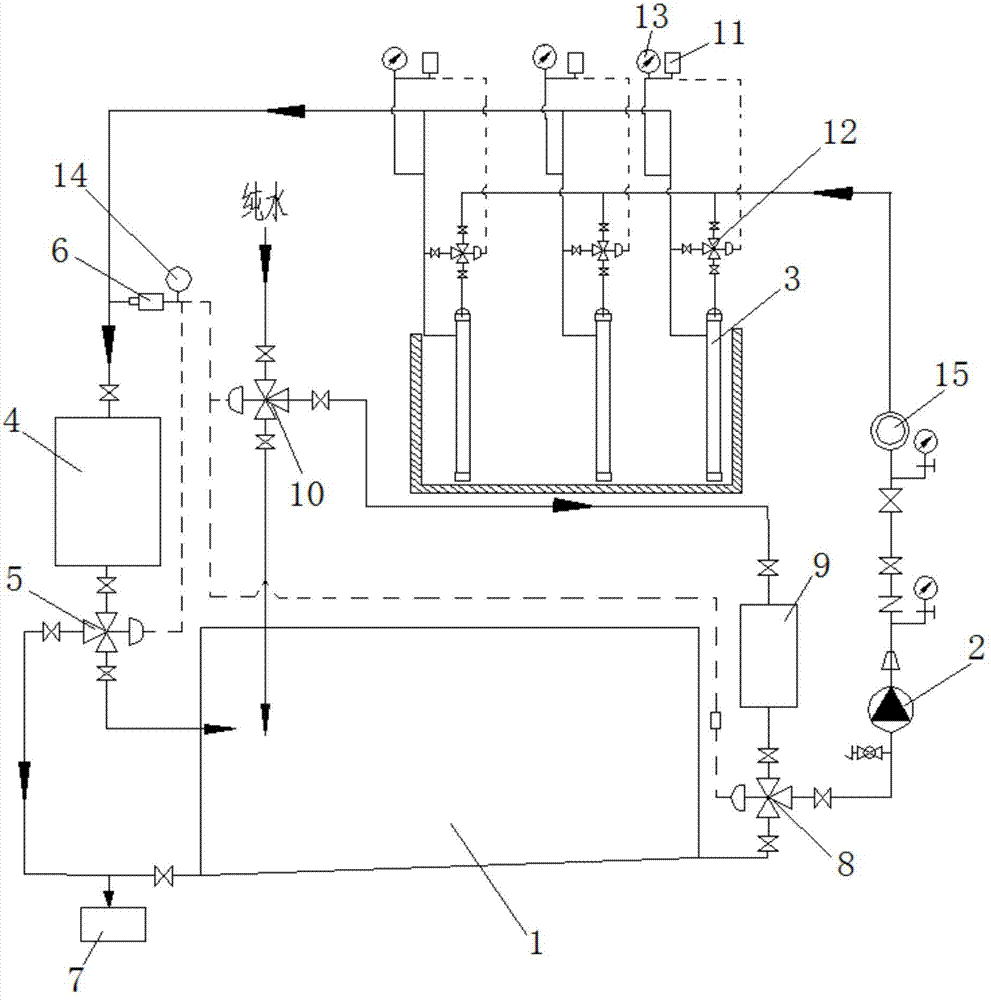

[0032] figure 2 It is a structural schematic diagram of the automobile coating anolyte circulation protection system proposed in the specific embodiment of the present invention.

[0033] Please refer to figure 2 , the specific implementation of the present invention proposes an automobile coating anolyte circulation protection system, which includes an anolyte storage tank 1, a circulation pump 2, an anode tube 3, an anolyte buffer tank 4, a first split three-way valve 5, a turbidity Degree meter 6, waste liquid tank 7, confluence three-way valve 8, pure water buffer tank 9, second diversion three-way valve 10, ammeter 13 and alarm 14;

[0034] The anolyte storage tank 1, the circulating pump 2, the anode tube 3, the anolyte buffer tank 4, and the first three-way valve 5 are connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com