Large-diameter steel mesh and method for connecting large-diameter steel mesh with connecting rods

A steel mesh, large-diameter technology, applied in the processing of building materials, construction, building reinforcements, etc., can solve problems such as the inability to adapt to the deviation of the steel bar axis and the length error, and the straight thread sleeve cannot be smoothly screwed into the steel wire head, etc. Achieve the effect of improving work efficiency and construction speed and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following describes the present invention in detail with reference to the accompanying drawings, but it is not intended to limit the present invention.

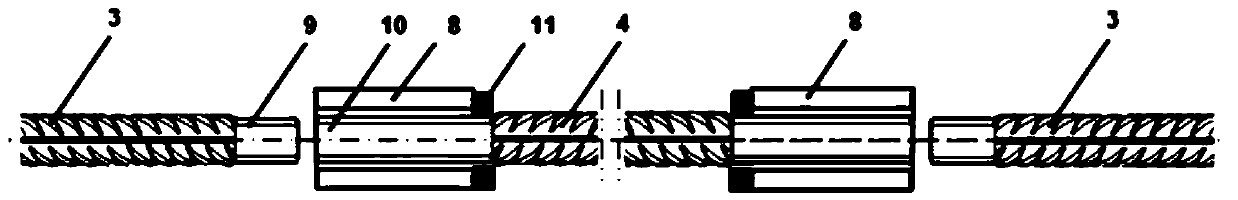

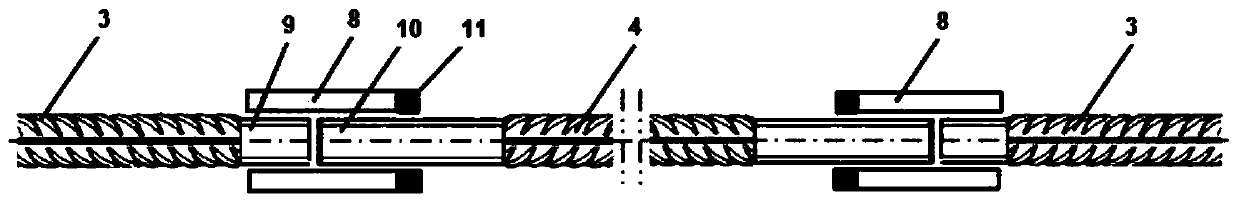

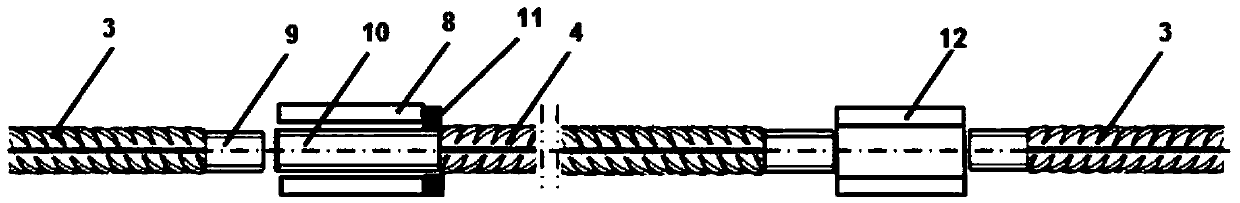

[0034] Such as Figure 8 As shown, the present invention discloses a large-diameter steel mesh, which includes a plurality of prefabricated large-diameter steel mesh units 1. Each large-diameter steel mesh unit 1 includes a plurality of transverse steel bars 3 and longitudinal steel bars 2 (the The longitudinal steel bars 2 and the transverse steel bars 3 are both large-diameter steel bars (hereinafter collectively referred to as main bars), and the intersection of the two can be fixed by lashing or welding), the size and shape of the large-diameter steel mesh unit 1 are not unique Each large-diameter steel mesh unit 1 can be the same in size and shape, or different. It can be determined according to the overall shape and structure of the large-diameter steel mesh that is actually required, but it should be ensured tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com