Slide stop mechanism released through cartridge clip

An empty warehouse and hang-up technology, which is applied to offensive equipment, weapon accessories, safety devices, etc., can solve problems such as shortening the time of changing bombs, and achieve the effect of convenient operation, simple structure, and shortened time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

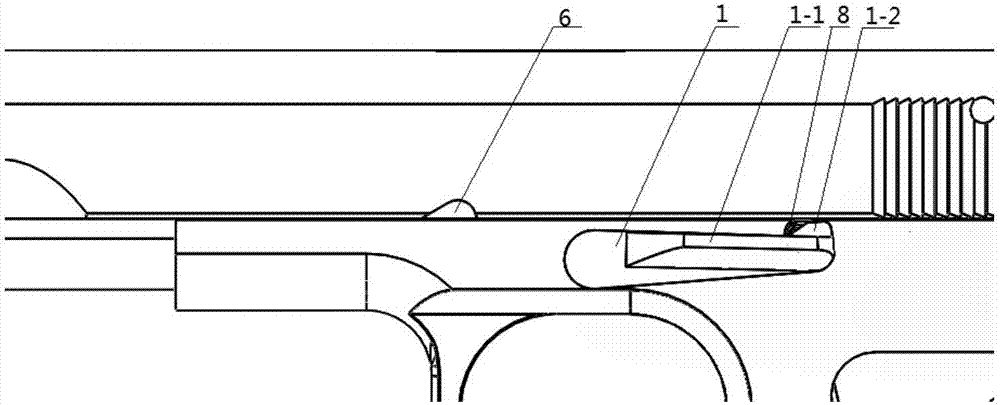

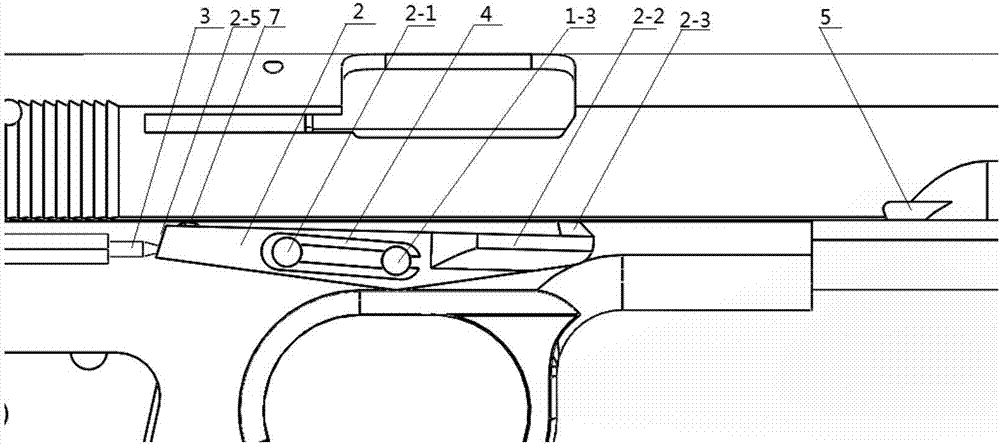

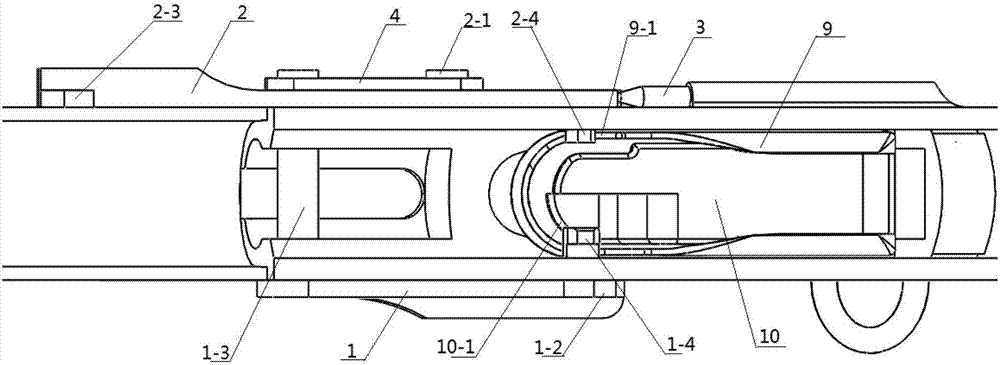

[0019] combine Figure 1-3 , a kind of hanger mechanism of the present invention that is freed from the clip includes a first hanger body 1, a snap spring 4, a second hanger body 2, a push rod mechanism 3, a spring plate 10 and a clip body 9; Holding a gun as an example, with the muzzle as the front end and the handle as the rear end; the first empty storage hanger body 1 and the second empty storage hanger body 2 are respectively located on the left and right sides of the gun body; the first empty storage hanger body 1 Including the first release handle 1-1, the first hanging table 1-2, the shaft 1-3 and the first shoot 1-4;

[0020] The rear end of the first hanger body 1 is provided with a first hanger 1-2, and the front end of the first hanger body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com