Double-lens double-bottom-light transverse synchronous movement system and image detector using same

A technology of synchronous movement and lens detection, applied in the direction of optical devices, instruments, measuring devices, etc., can solve the problems of complex structure and high cost of image detectors, and achieve the effect of high detection efficiency, simple structure and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to describe the technical content, structural features, achieved objects and effects of the present invention in detail, the following detailed description is given in conjunction with the embodiments and the accompanying drawings.

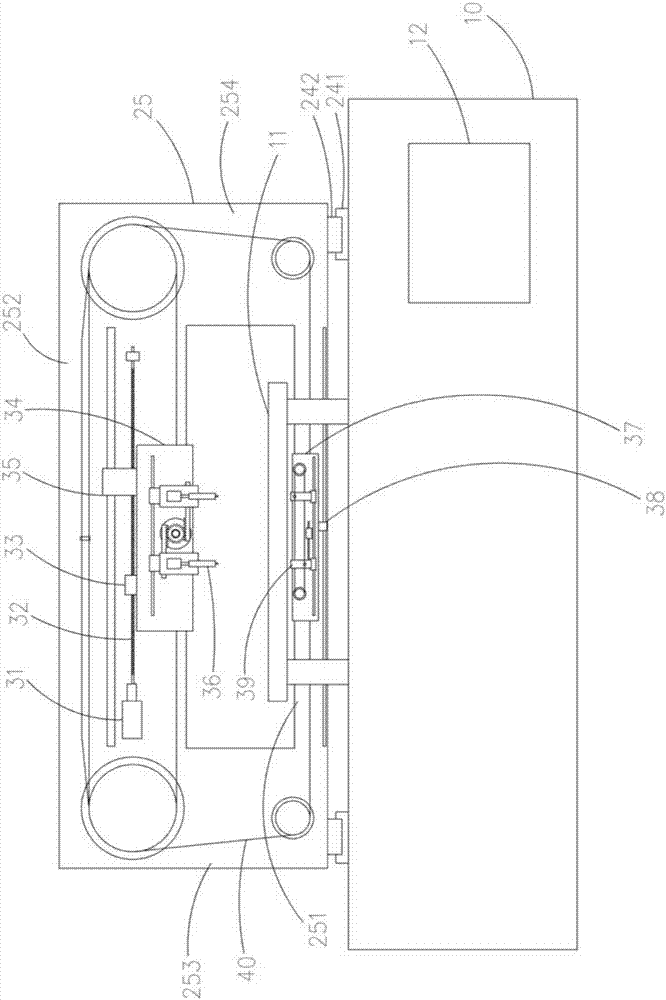

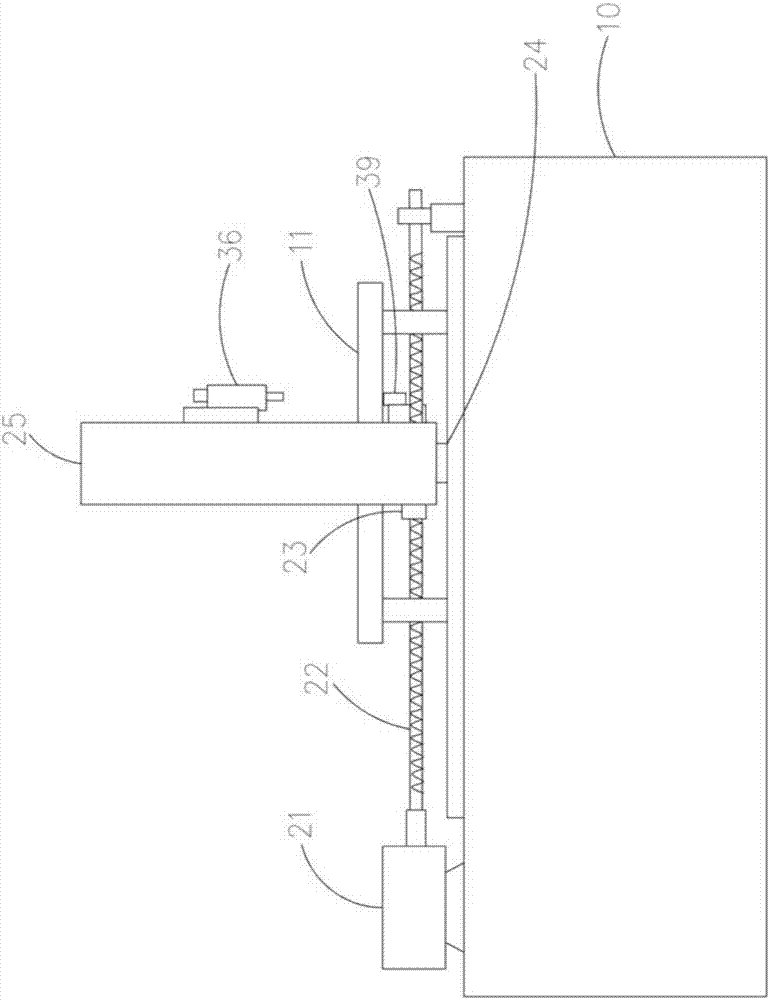

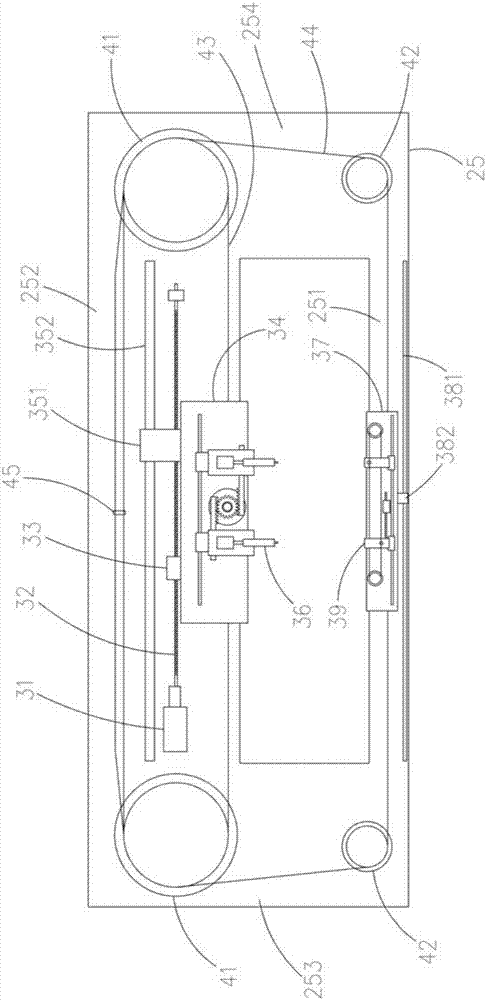

[0047] see figure 1 , 2 , the present invention is an image detector using a dual-lens and dual-bottom light lateral synchronous movement system, including a chassis 10, a workpiece table 11, a longitudinal rotation motor 21, a longitudinal screw 22, a longitudinal nut 23, a longitudinal guide member 24, and a gantry frame. 25 and manipulation detection system 12 .

[0048] An overhead fixed workpiece table 11 is arranged at the middle position of the top surface of the bottom frame 10 for placing the workpiece to be inspected; the front and rear longitudinal longitudinal rotation motors 21 and the longitudinal screw rods 22 are arranged at the position where the top surface of the bottom frame 10 is located below the workpiece ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com