Test device carrying out generator iron core magnetization under voltage and method thereof

A test device and generator technology, applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve the problems of large closing current power shock, large power supply capacity, large deviation between test magnetic flux and theoretical value, etc. The effect of improving the accuracy of the test, improving the safety and reliability, and shortening the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

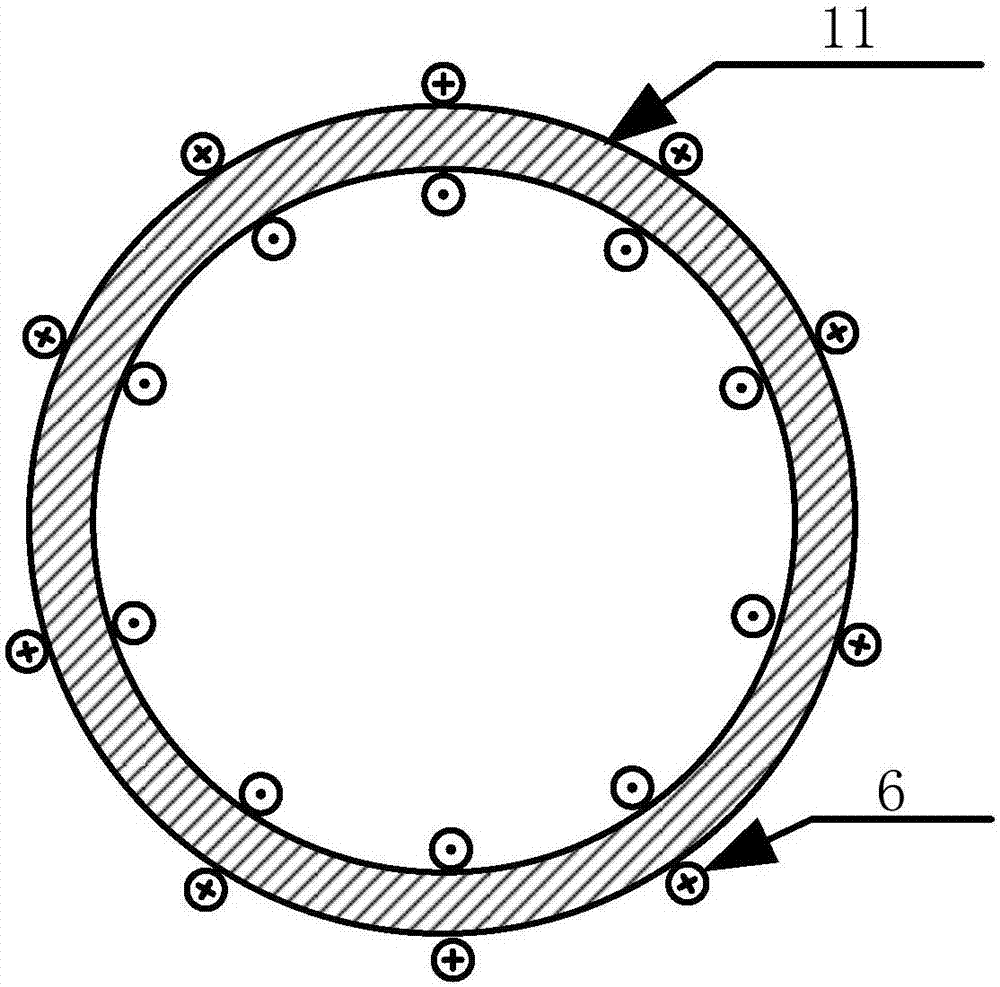

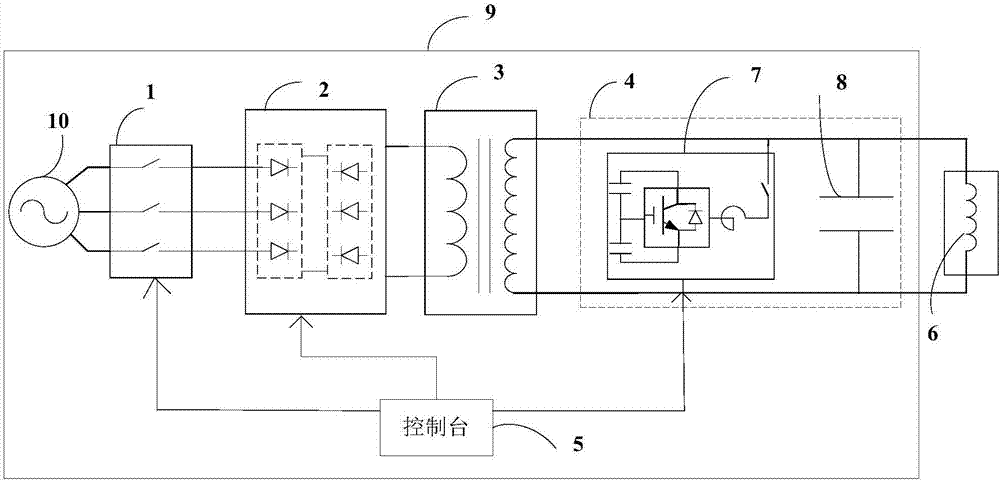

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0033] The inventive test device has a simple wiring arrangement during the test, and the excitation coil is multi-turn parallel connection, which shortens the winding time of the excitation coil and saves manpower; the test operation is easy, and there is no closing inrush current. The voltage is continuously adjustable, effectively avoiding the inrush current caused by direct closing; reducing the small capacity of the test power supply, the reactive power automatic tracking compensation device developed by the project, 100% compensates the reactive current of the test, thereby reducing the requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com