Cement plant pressure fan energy-saving control system

An energy-saving control system and compressor technology, applied in pump control, mechanical equipment, machines/engines, etc., can solve the problems of unstable speed, inability to save energy, and low precision of speed regulation, so as to solve the problem of start-up shock and improve the effective Utilization, the effect of wide range stepless speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

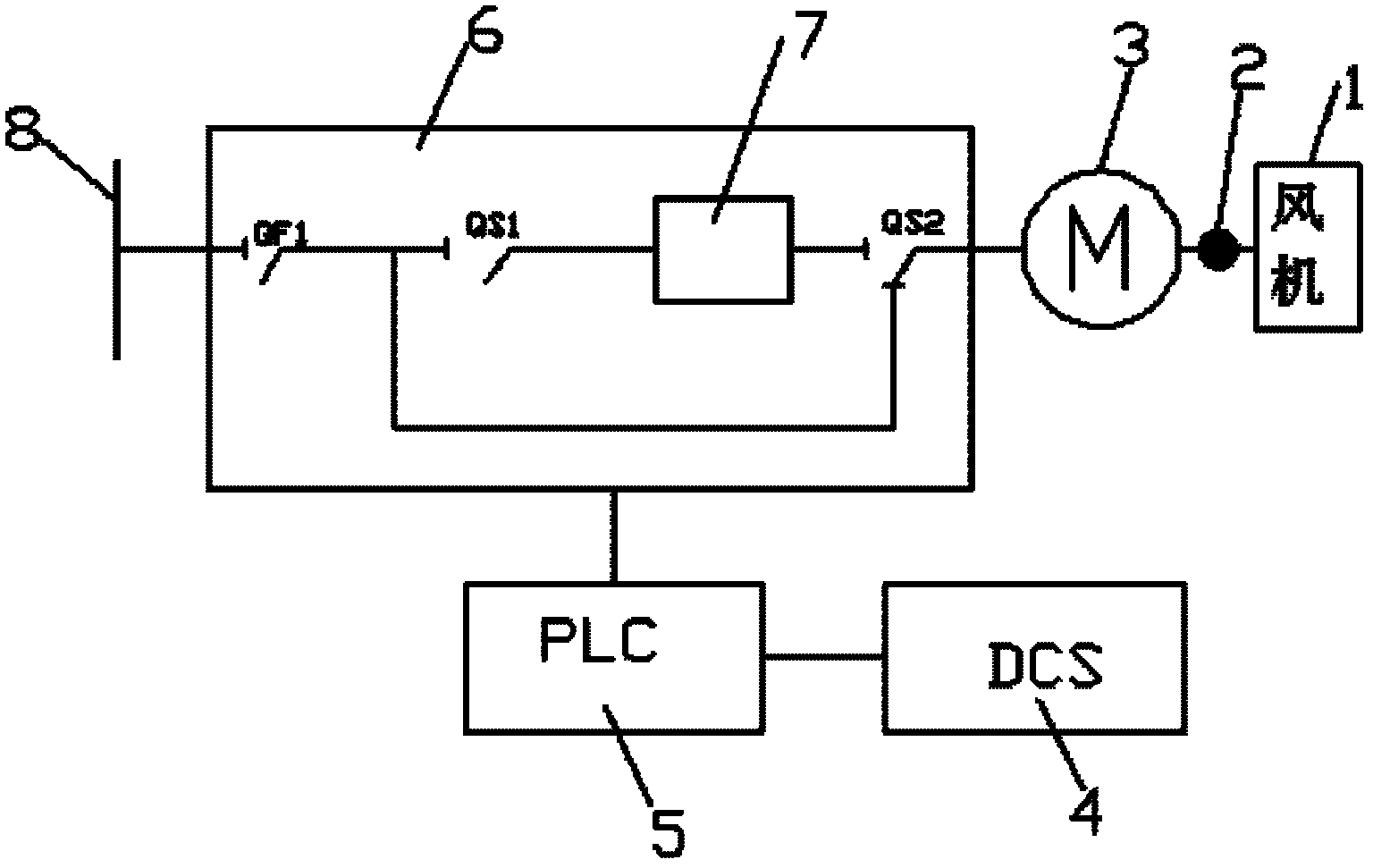

[0014] An energy-saving control system for a pressurized fan in a cement plant, including a fan 1, a universal joint coupling 2, a motor 3, a distributed control system (DCS) signal converter 4, a programmable logic controller (PLC) 5, and a motor drive controller 6. The distributed control system signal converter, programmable controller, motor drive controller, motor, universal joint coupling and fan are connected in sequence, and the motor drive controller includes a first switch QF1, a second switch QS1, the third switch QS2 and the frequency converter 7, the third switch is a single-pole double-throw switch, one end of the first switch is connected to the high-voltage bus 8, and the other end of the first switch is respectively connected to one end of the second switch and the first One static contact of the three switches, the other end of the second switch is connected to one end of the frequency converter, the other end of the frequency converter is connected to the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com