High-voltage and high-frequency transformer and winding method therefor

A winding method, high-voltage and high-frequency technology, applied in the direction of inductor/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, transformer/inductor parts, etc., can solve the problem of low isolation voltage and low safety protection level , large volume and other issues, to achieve the effect of high isolation voltage and strong practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

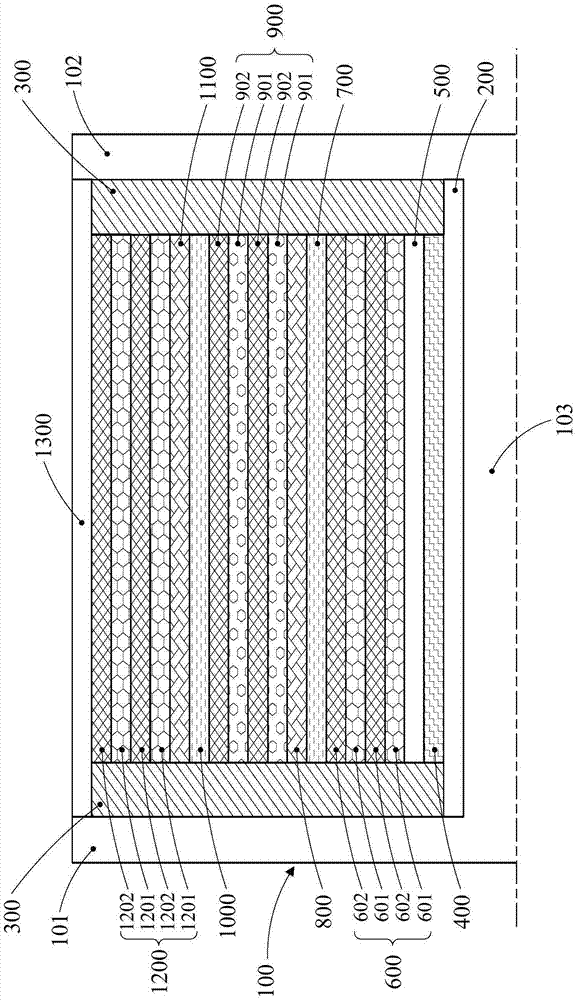

[0036] This embodiment provides a high-voltage and high-frequency transformer. The magnetic core in the transformer is made of high-frequency magnetic materials, such as ferrite materials; the wires in the transformer are high-voltage and high-frequency cables, such as Triple-layer insulated wire or enameled wire. Such as figure 1 As shown, the high-voltage and high-frequency transformer includes: a skeleton 100, and a first inner insulating layer 200, a magnetic shielding layer 400, a second inner insulating layer 500, The first primary side layer 600 , the first primary side insulating layer 800 , the secondary side layer 900 , the second primary side insulating layer 1100 , the second primary side layer 1200 and the outer insulating layer 1300 .

[0037] Wherein, the frame 100 includes a middle part 103 and two end parts 101 and 102 respectively located on both sides of the middle part, and the frame is bent at the two ends 101 and 102, and the above-mentioned first inner ...

Embodiment 2

[0050] This embodiment provides a winding method for a high-voltage and high-frequency transformer. The transformer includes a skeleton, and the skeleton includes a middle part and two ends respectively located on both sides of the middle part, and the skeleton is folded at the two ends. The inner surfaces of the two ends are opposite to each other, and the outer surfaces of the two ends are opposite to each other. The magnetic core in the transformer is made of high-frequency magnetic material, for example, ferrite material; the wire in the transformer is a high-voltage high-frequency cable, such as triple-layer insulated wire or enameled wire.

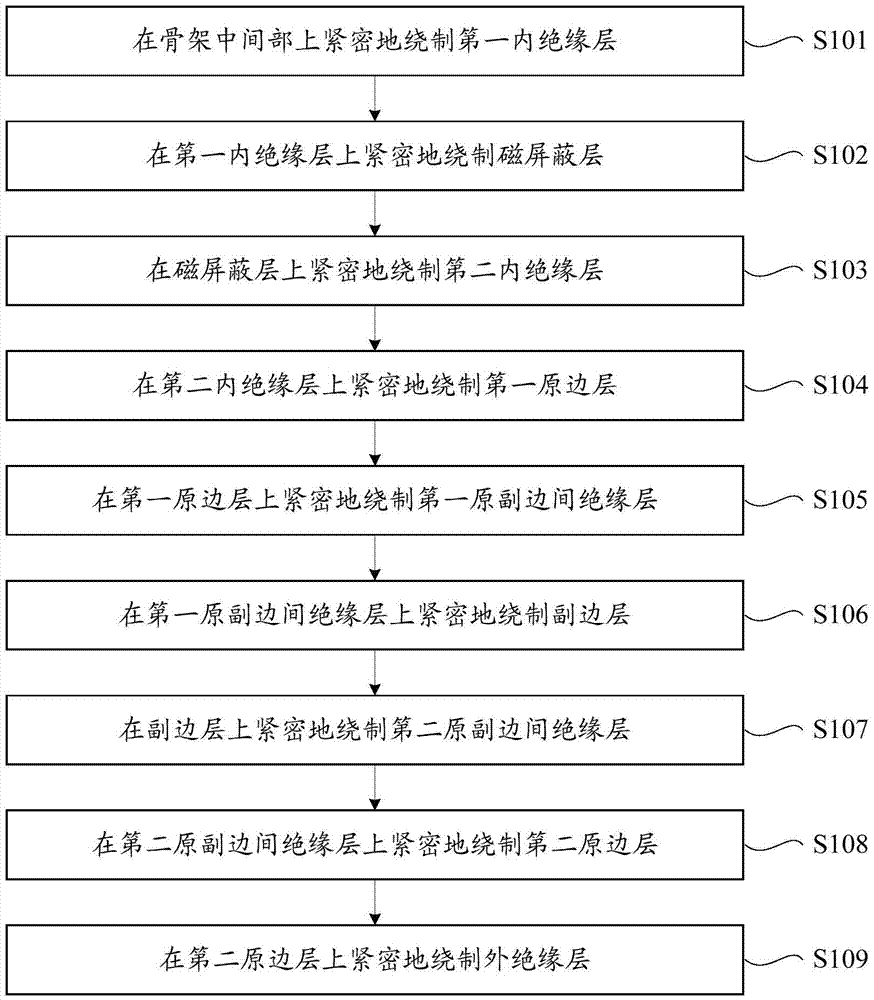

[0051] The winding method comprises the steps of:

[0052] The first inner insulating layer, the magnetic shielding layer, the second inner insulating layer, the first primary side layer, the first primary and secondary insulating layer, the secondary side layer, the second The insulating layer between the two primary and secondary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com