Plate cutting machine

A cutting machine and cutting mechanism technology, applied in sawing components, sawing equipment, wood processing appliances, etc., can solve the problems of arching, warping or offset, affecting the processing accuracy of the plate, and the distance between the tools is not adjustable. The effect of no arching, high work efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

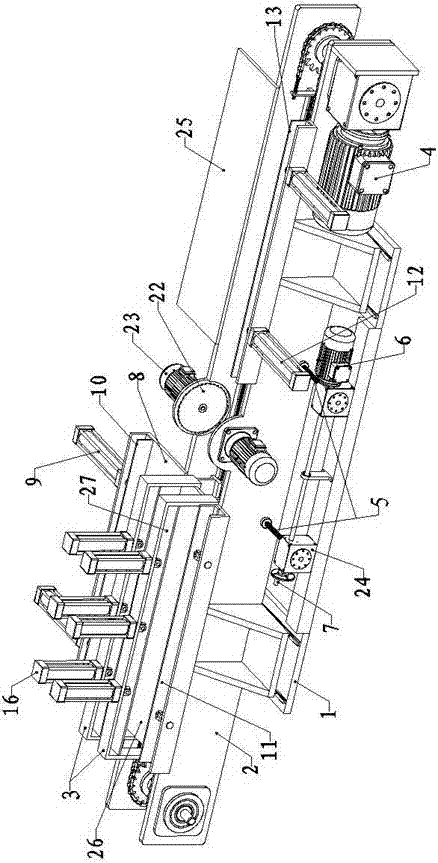

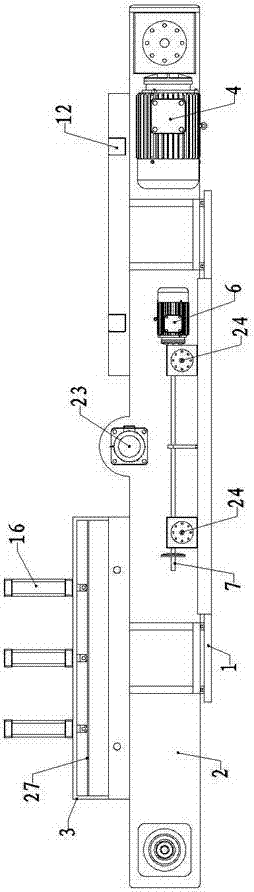

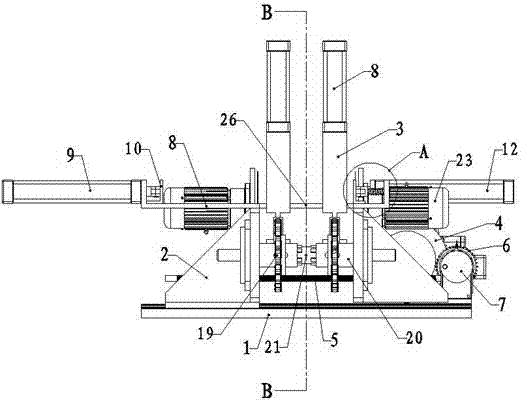

[0023] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

[0024] Such as Figure 1~Figure 7 As shown, a plate cutting machine includes a base 1, a spacing adjustment bracket 2, a feeding bracket 3, a feeding mechanism, a discharging mechanism, a positioning mechanism, a clamping mechanism and a cutting mechanism.

[0025] The two spacing adjustment brackets 2 are symmetrically and linearly slidable mounted on the base 1, and the specific method can be a linear guide rail. A spacing adjustment mechanism is provided between the two spacing adjustment brackets 2. The spacing adjustment mechanism includes a lead screw 5, a screw drive motor 6 and a manual crank 7. The two spacing adjustment brackets 2 are provided with internal threads with opposite rotation directions. The spacing adjusting brackets 2 are all threaded with the leadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com