Narrow-particle size distribution PbS quantum dot-doped glass and preparation method thereof

A technology of quantum dot glass and doped glass, which is applied in the field of PbS quantum dot doped glass and its preparation, can solve the problems that quantum dots are not easy to control, restrict the application and development of quantum dot doped glass, and have a wide particle size distribution of quantum dots. , to achieve the effect of simple preparation method, strong luminescence performance and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Prepare the PbS quantum dot-doped glass with narrow particle size distribution, the method is as follows:

[0019] 1) Preparation of glass substrate: 50SiO2 according to molar percentage 2 -25Na 2 O-5Al 2 o 3 -7.2ZnO-10CaO-2ZnS-0.8PbO After weighing the raw materials and mixing them evenly, they are melted in a high-temperature furnace at 1400°C and formed, and annealed to eliminate stress.

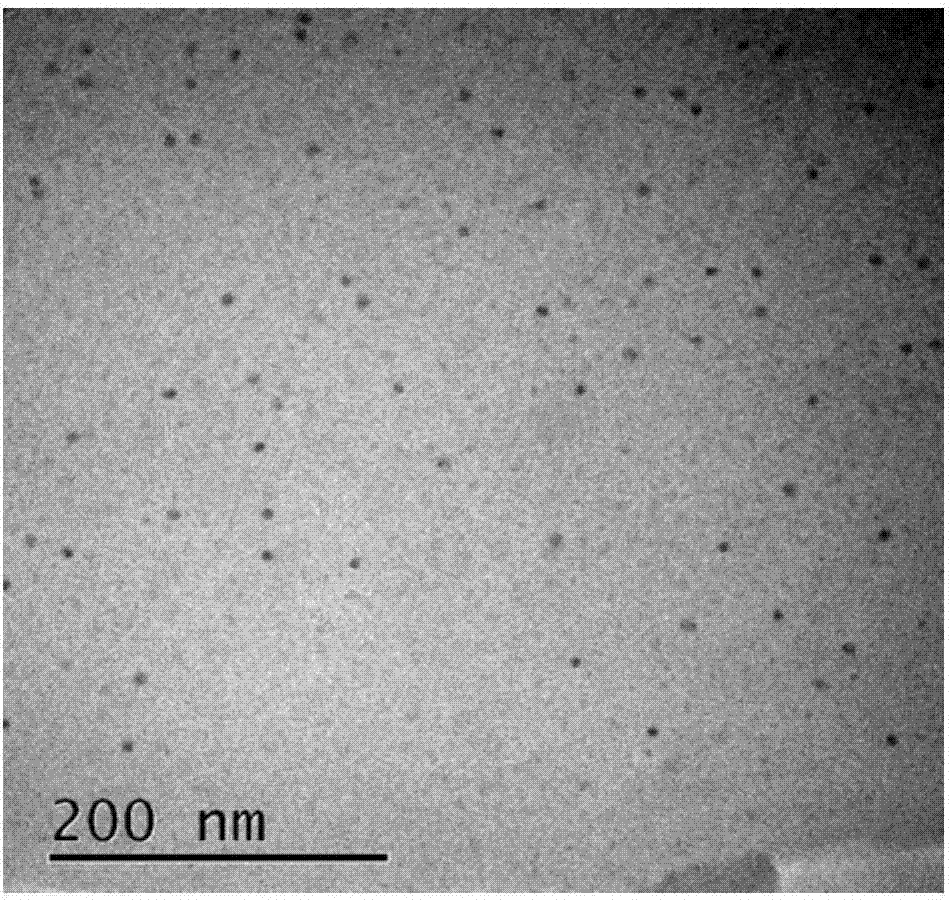

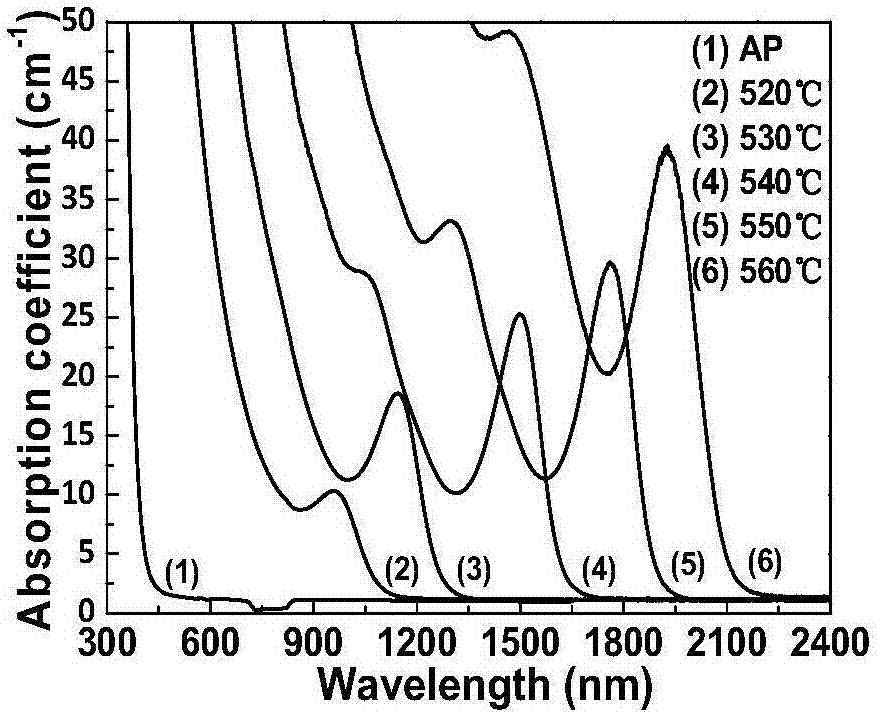

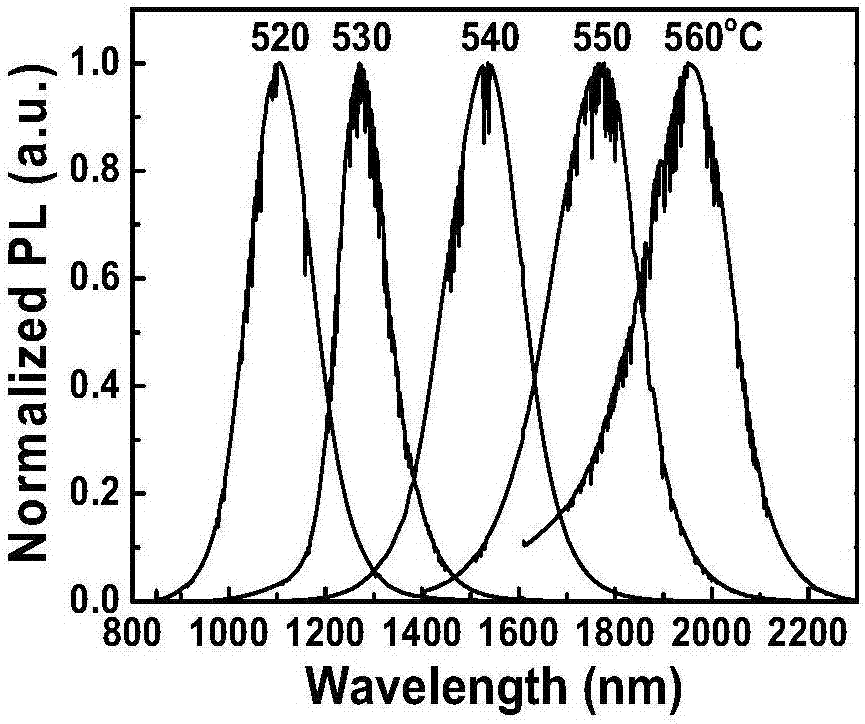

[0020] 2) Prepare PbS quantum dot-doped glass; heat-treat the glass obtained in step 1) at temperatures of 520°C, 530°C, 540°C, 550°C and 560°C for 10 hours, thereby preparing the average particle size in the glass matrix. The particle size distributions of PbS quantum dots of 1.87nm, 2.28nm, 3.20nm, 4.01nm and 4.66nm are 7.30%, 6.03%, 4.91%, 5.42% and 6.88%, respectively. Taking 1.87nm and particle size distribution of 7.30% as an example, the particle size is within the range of 1.87±(1.87*7.30%)=1.73nm-2.01nm.

[0021] After testing, the central wavelengths of the absorptio...

Embodiment 2

[0027] Prepare the PbS quantum dot-doped glass with narrow particle size distribution, the method is as follows:

[0028] 1) Preparation of glass substrate: 52SiO according to molar percentage 2 -20Na 2 O-7Al 2 o 3 -6.4ZnO-11CaO-3ZnS-0.6PbO, after weighing the raw materials and mixing them evenly, they are melted in a high temperature furnace at 1400°C and formed, and annealed to eliminate stress.

[0029] 2) Prepare PbS quantum dot-doped glass; heat-treat the glass obtained in step 1) at temperatures of 510°C, 520°C, 530°C, 540°C, 550°C and 560°C for 10 hours, thereby preparing average PbS quantum dots with particle sizes of 1.34nm, 1.49nm, 2.16nm, 2.40nm, 3.10nm and 4.02nm respectively have particle size distributions of 10.18%, 10.05%, 6.86%, 5.89%, 6.19% and 7.18%.

[0030] After testing, the central wavelengths of the absorption peaks of the narrow particle size distribution PbS quantum dot-doped glass prepared in this example are 703nm, 787nm, 1079nm, 1179nm, 1459nm ...

Embodiment 3

[0033] Prepare the PbS quantum dot-doped glass with narrow particle size distribution, the method is as follows:

[0034] 1) Preparation of glass substrate: 50SiO2 according to molar percentage 2 -22Na 2 O-6Al 2 o 3 -5.8ZnO-12CaO-4ZnS-0.2PbO), weigh the raw materials and mix them evenly, melt them in a high-temperature furnace at 1400°C, shape them, and anneal them to eliminate stress.

[0035]2) Prepare PbS quantum dot-doped glass; heat-treat the glass substrate obtained in step 1) at temperatures of 500°C, 510°C, 520°C, 530°C, 540°C, 550°C and 560°C for 10 hours, so that the glass substrate PbS quantum dots with average particle diameters of 1.40nm, 1.52nm, 1.74nm, 2.07nm, 3.12nm, 4.12nm and 5.88nm were prepared, and the particle size distributions were 8.66%, 7.75%, 7.87%, 7.87% , 5.49%, 5.12% and 6.38%.

[0036] After testing, the central wavelengths of the absorption peaks of the narrow particle size distribution PbS quantum dot-doped glass prepared in this example a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com