Nano microcrystalline glass containing stannic oxide and preparation method of nano microcrystalline glass

A nano-crystal and tin dioxide technology, applied in the field of inorganic light-emitting materials, can solve the problems of application requirements that cannot meet high brightness, poor light-emitting effect of glass materials, etc., and achieve the effects of easy operation, improved light-emitting, and improved light-emitting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of nano glass ceramics containing tin dioxide, comprising the steps of:

[0046] (1) Porous glass solution doping;

[0047] Configure SnCl 4 and EuCl 3 A mixed aqueous solution of which, Sn 4+ The concentration is 0.8mol / L, Eu 3+ The concentration is 0.4mol / L. Porous glass (the preparation method of porous glass is: SiO 2 , B 2 o 3 、Al 2 o 3 、Na 2 CO 3 Mix it with CaO powder raw material according to the weight percentage of 51:29:1.6:13:5.4, burn at 1400°C for 2 hours, pour out the molten glass, put it into a muffle furnace at 600°C for 24 hours for phase separation, and then heat it at 100°C Soak in 1mol / L hot hydrochloric acid for 24 hours to obtain porous glass; the pore size of the porous glass is 4-50nm) and immerse in the above mixed solution for 30 minutes; take it out and blow dry at 10°C-120°C or dry it by yourself.

[0048] (2) Initial heat treatment;

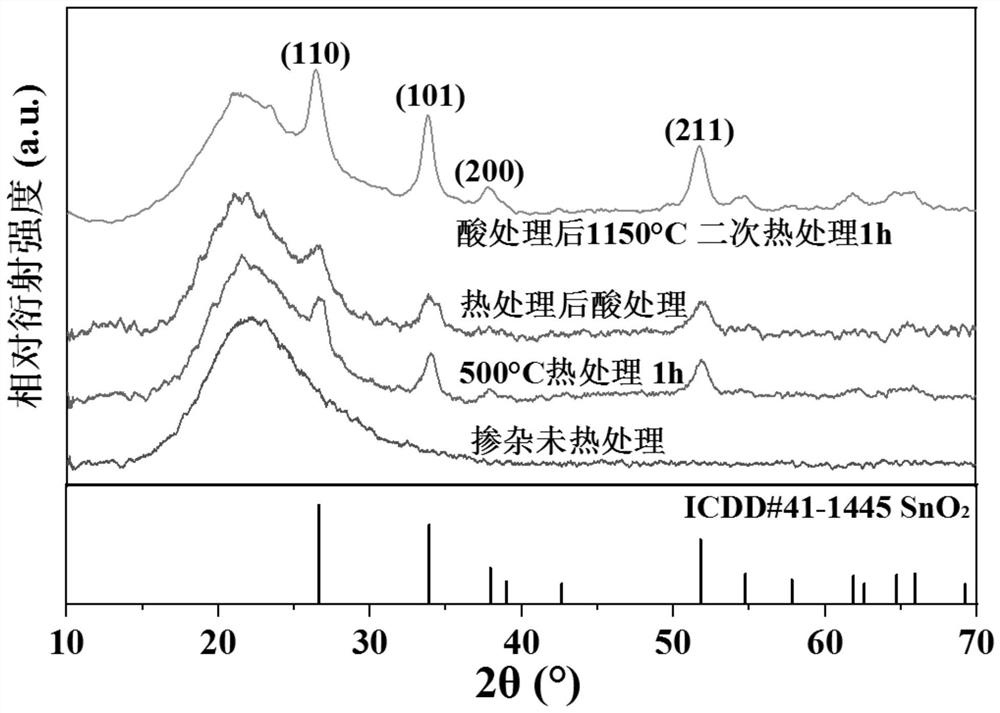

[0049] Heating the porous glass obtained in step (1) at 500° C. for 1 h; ...

Embodiment 2

[0057] The method of processing porous glass in the common method doping mode to prepare nano glass-ceramics containing tin dioxide (i.e. the acid-free treatment preparation method of porous glass): the doped dry porous glass obtained in step (1) of Example 1 is directly placed in The co-doped Eu 3+ and SnO 2 Nanocrystalline glass.

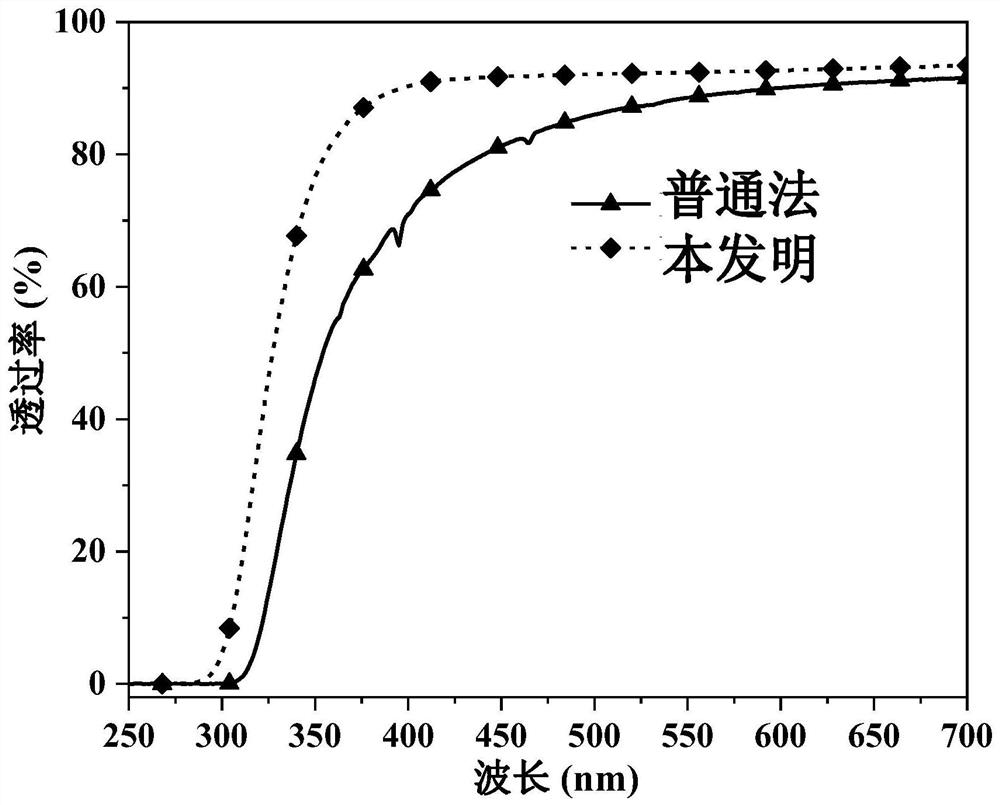

[0058] The tin dioxide-containing nano-glass-ceramics prepared by doping according to the above common method was compared with the tin-oxide-containing nano-glass-ceramics prepared by the method described in Example 1 of the present invention.

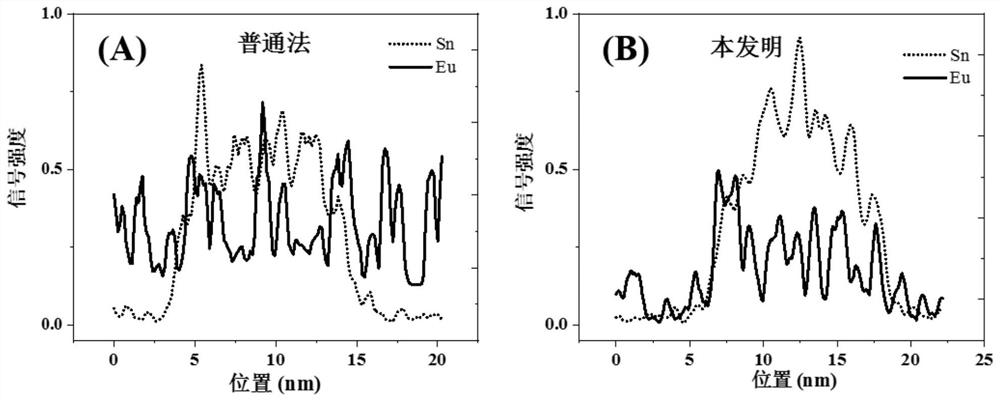

[0059] The distribution of Eu ions in the tin dioxide-containing nano glass-ceramics prepared by the above two methods is as follows: figure 2 shown. from figure 2 It can be seen that the Eu ions of the tin dioxide-containing nanoglass-ceramics prepared by the ordinary method doping method for porous glass are substantially evenly distributed inside and outside the tin dioxide crystals, while the Eu...

Embodiment 3

[0063] Implementation method is the same as embodiment 1, but present embodiment puts EuCl 3 Replaced by Er(NO 3 ) 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com