Patents

Literature

55 results about "Nano crystallites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-source precursors for ternary chalcopyrite materials, and methods of making and using the same

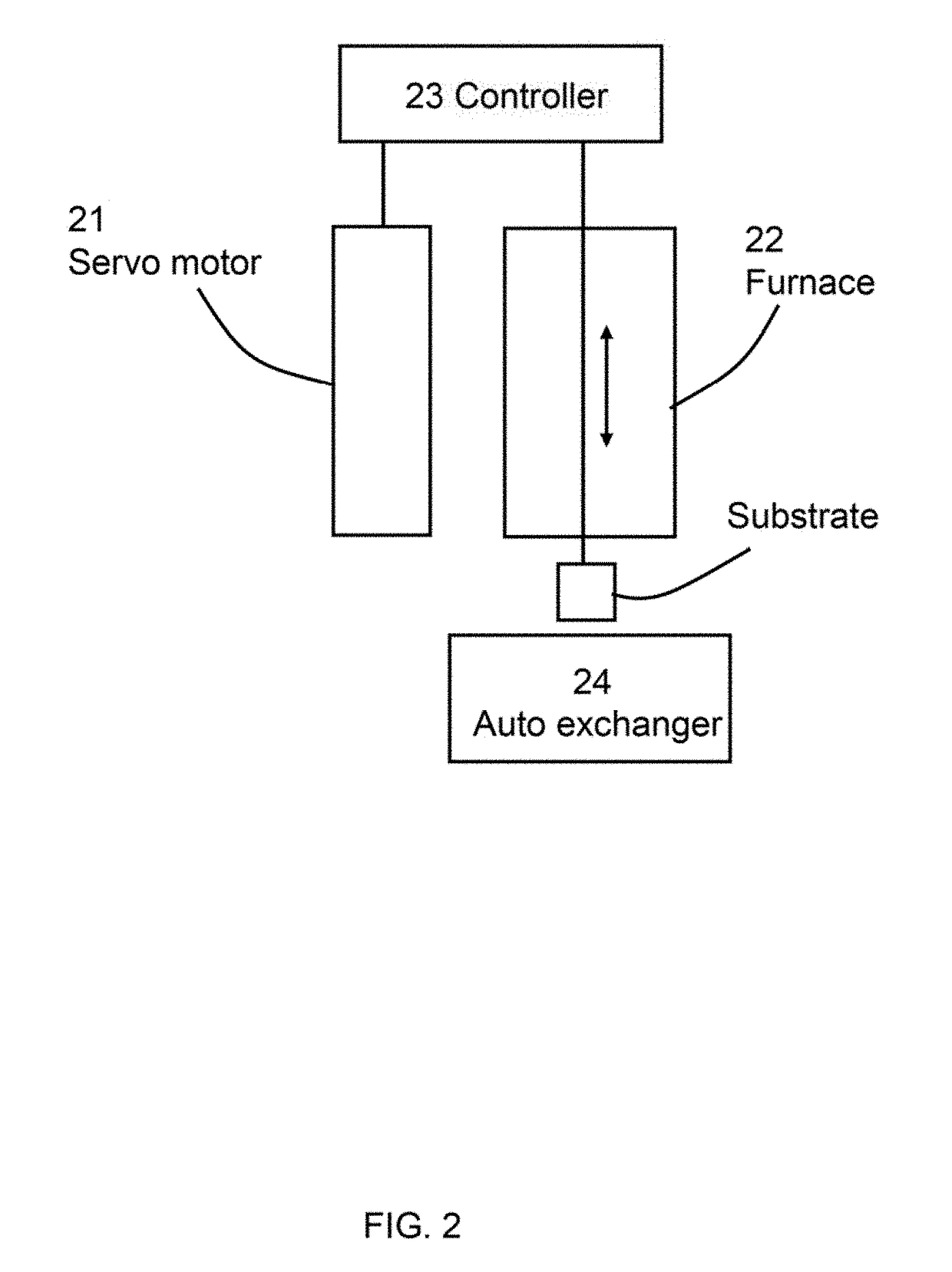

InactiveUS6992202B1Effective yieldFurnaces without endless coreMaterial nanotechnologyChalcopyriteQuantum dot

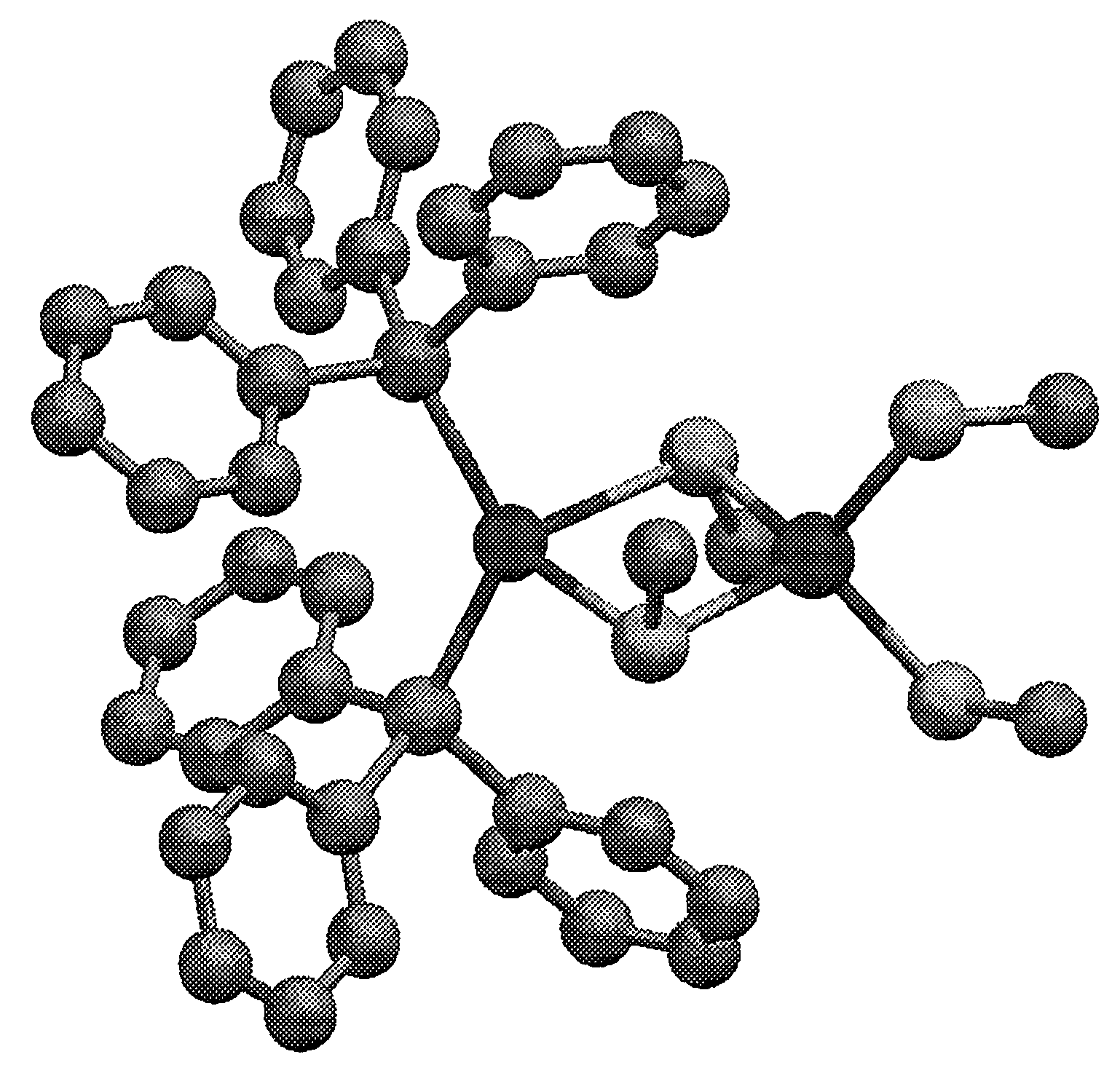

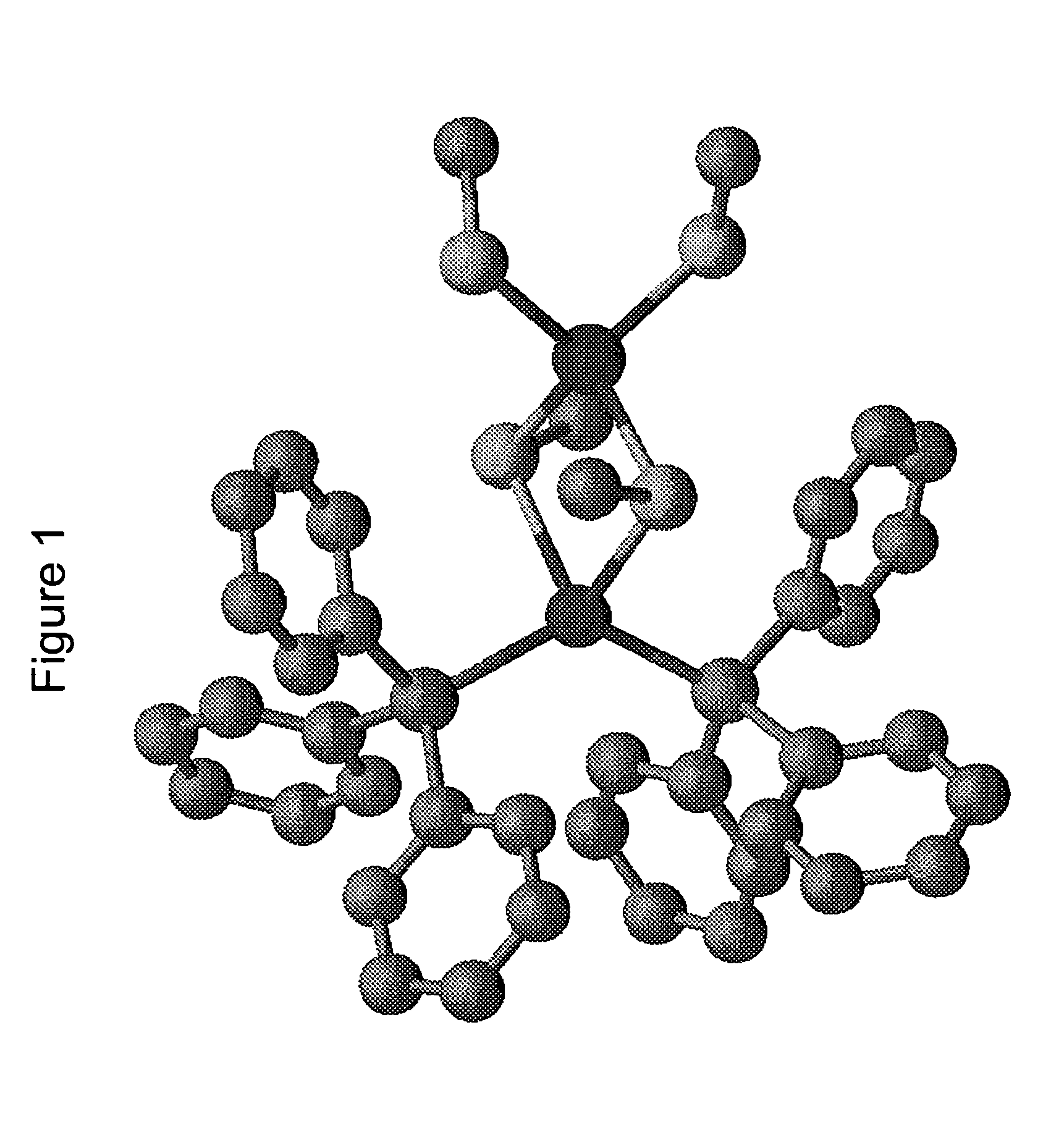

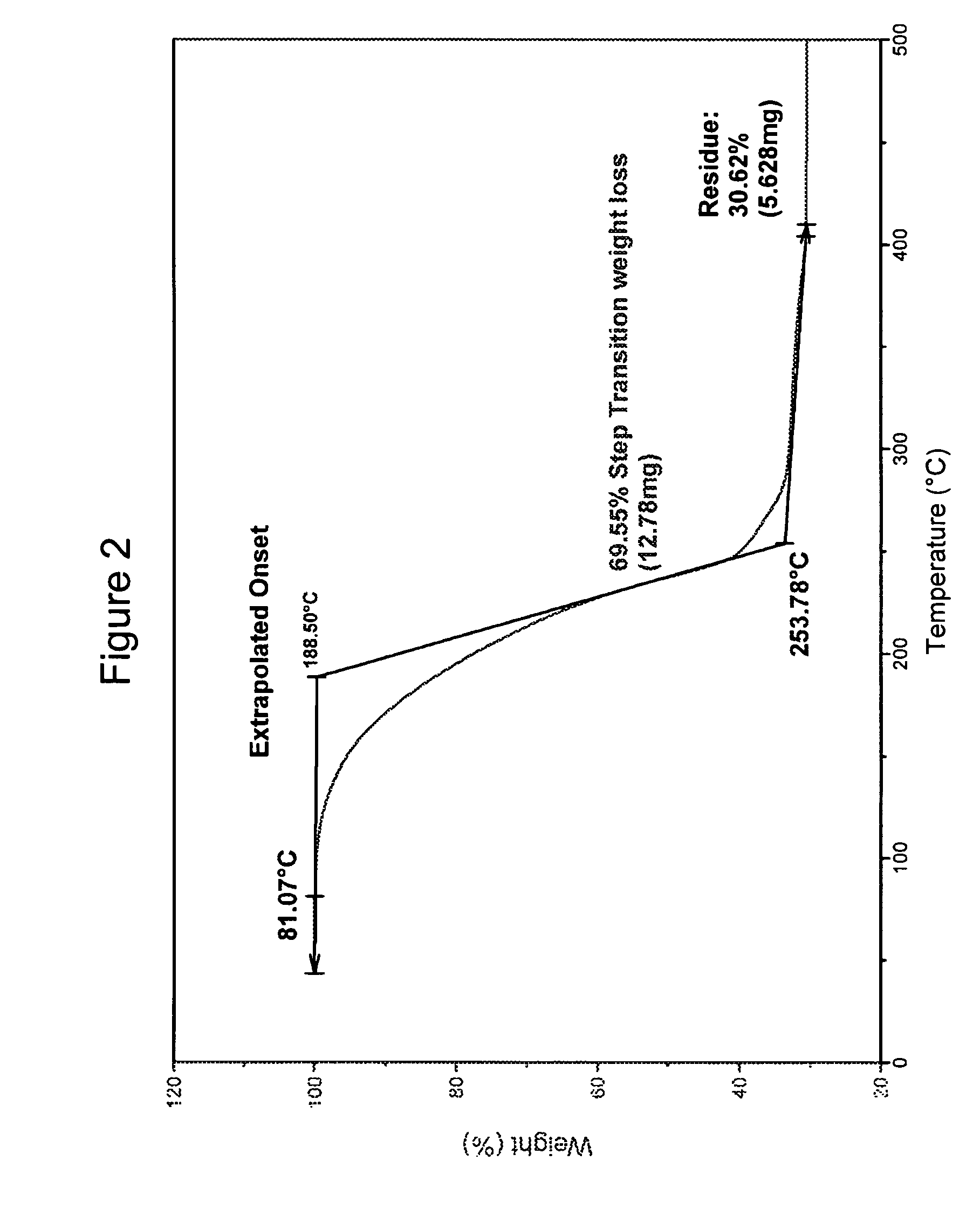

A single source precursor for depositing ternary I-III-VI2 chalcopyrite materials useful as semiconductors. The single source precursor has the I-III-VI2 stoichiometry “built into” a single precursor molecular structure which degrades on heating or pyrolysis to yield the desired I-III-VI2 ternary chalcopyrite. The single source precursors effectively degrade to yield the ternary chalcopyrite at low temperature, e.g. below 500° C., and are useful to deposit thin film ternary chalcopyrite layers via a spray CVD technique. The ternary single source precursors according to the invention can be used to provide nanocrystallite structures useful as quantum dots. A method of making the ternary single source precursors is also provided.

Owner:OHIO AEROSPACE INST +1

Nano crystallite composite filter material and supplement of manufacture method thereof

The invention extends the connotation range required to be protected on the basis of a previously issued patent ZL200710025045.4, i.e., a nanometer microcrystalline composite filter material and a preparation method thereof, belonging to the field of a water disposal technique material. According to weight percentage, the nanometer microcrystalline composite filter material comprises 3-95 percent of attapulgite clay, 5-80 percent of sepiolite clay, 2-25 percent of kaolinite clay, 2-97 percent of tubular halloysite, 5-75 percent of diatomite, 5-75 percent of natural zeolite (clinoptilolite, mordenite and the like), 0-25 percent of pillared montmorillonite, 0-50 percent of expanded vermiculite, 0-5 percent of expanded perlite and 0-50 percent of active carbon or bamboo carbon powders. All raw materials which are powder shapes are mixed according to proportion and stirred to granulate by adding an inorganic adhesive, then sintered and activated at the temperature of 900-500 DEG C (inert gas is required for sintering and activating the filter material added with active carbon). The nanometer microcrystalline composite filter material has smooth shape, rough surface and uniform particle size, with the diameter of 1-10mm, and is used for biological filter tanks and high-class adsorption filter materials in deep purification systems of drinking water and reclaimed water sewage disposal systems.

Owner:傅成义

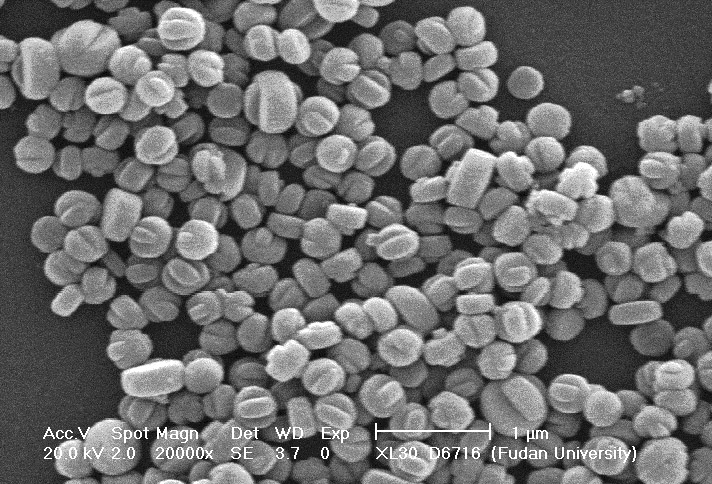

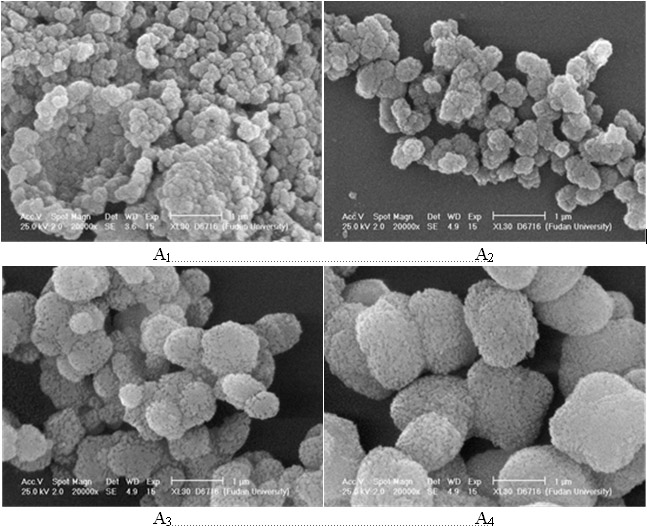

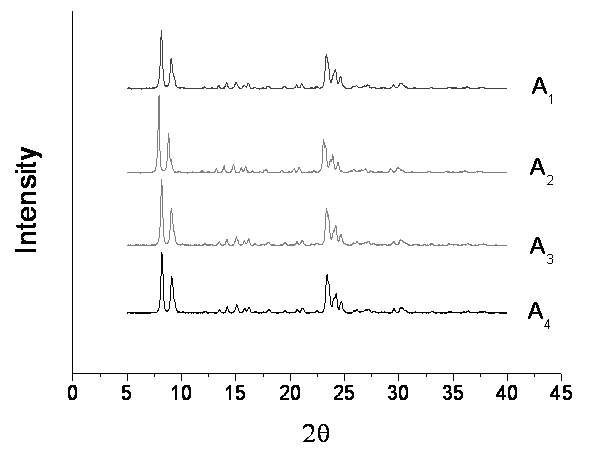

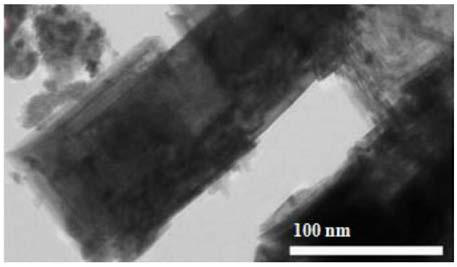

Method for synthesizing ZSM-5 zeolite orderly accumulated by nanometer crystallite

InactiveCN101983921AAdjustable sizeThickness is easy to controlPentasil aluminosilicate zeolitePhysical chemistryCrystallinity

The invention belongs to the technical field of zeolite materials, in particular to a method for synthesizing ZSM-5 zeolite orderly accumulated by nanometer crystallite. The method comprises the following steps: adding MFI type zeolite seed crystal in a common ZSM-5 zeolite synthesizing solution; and synthesizing the ZSM-5 zeolite with multistage pore canals and controllable granular size by modulating the synthesizing ration, reaction condition or adding additives. In the invention, the ZSM-5 zeolite is an assembly body of a class of single crystals, which is grown by orderly packing seed crystals by ZSM-5 zeolite crystallite, has small granular and a multistage pore canal structure, larger surface area, shorter mass transfer route, good stability, and can be used for reactions for diffusion control or the surface activity site control. The method has short hydro-thermal treatment time, high crystallinity and yield and the like, and is convenient to separate the ZSM-5 zeolite.

Owner:FUDAN UNIV +1

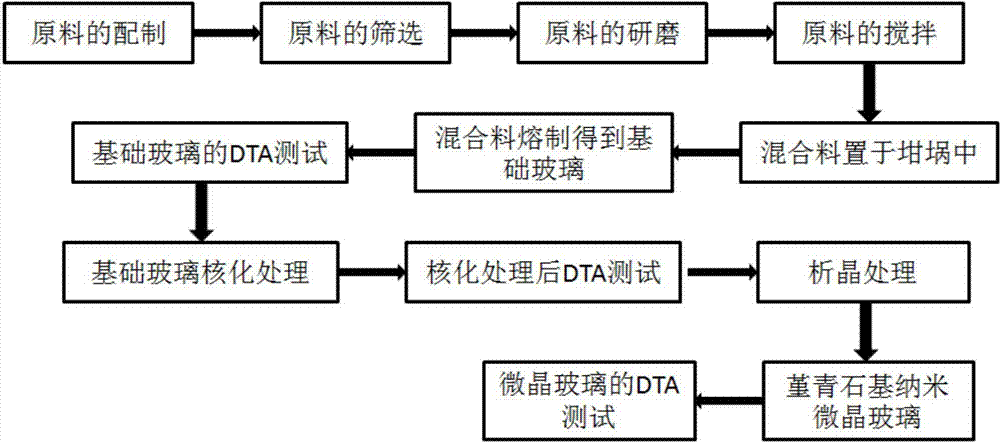

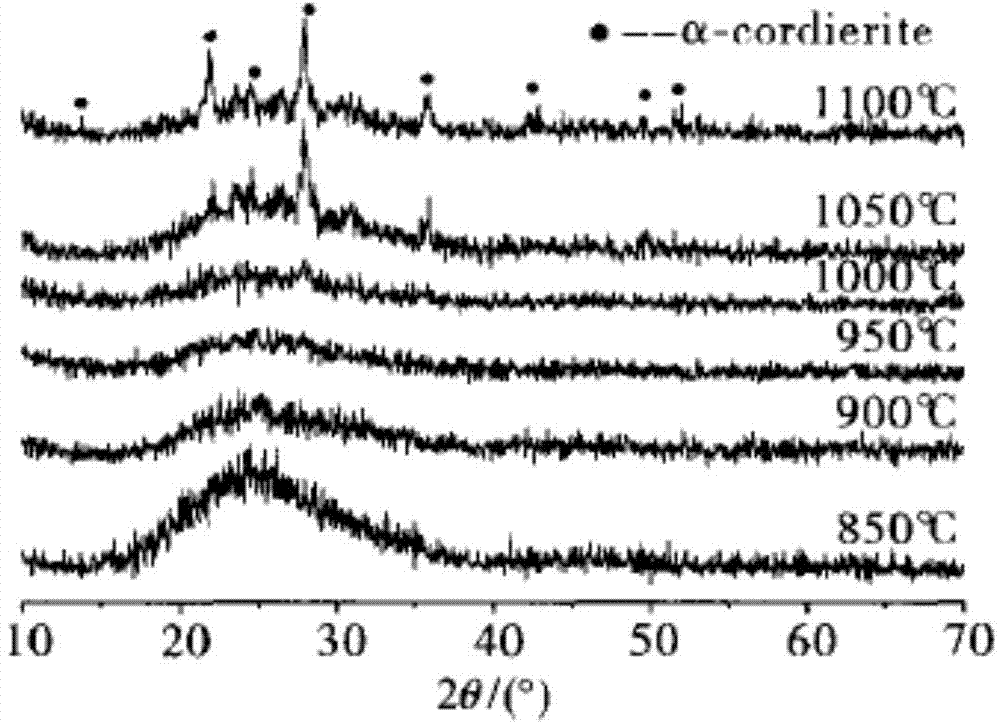

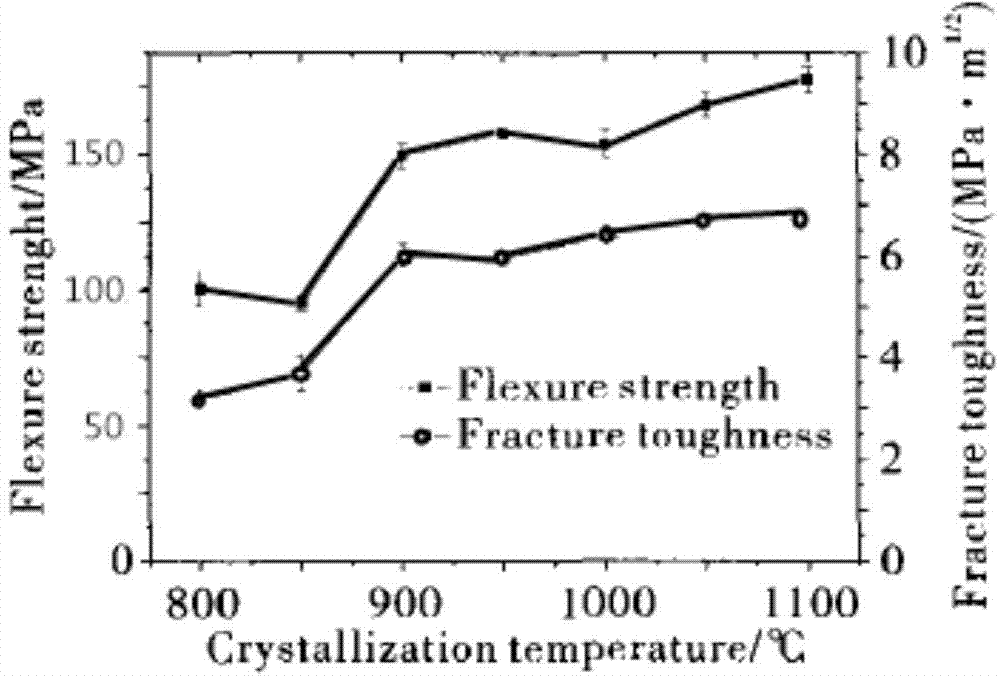

Cordierite-based nanometer glass-ceramic and preparation method thereof

The invention provides a cordierite-based nanometer glass-ceramic. The cordierite-based nanometer glass-ceramic comprises a main component, a nucleating agent, an adjustment object and a fluxing agent, wherein the main component comprises SiO2, MgO and Al2O3; the nucleating agent comprises one or a plurality of TiO2, ZrO2 and P2O5, and accounts for 2.0-20wt% of the main component; the adjustment object comprises one or a plurality of CaO, Na2O and K2O, and accounts for 0.1-1wt% of the main component; and the fluxing agent comprises B2O3, and accounts for 1.0-3.0wt% of the main component. The cordierite-based nanometer glass-ceramic provided by the invention has higher mechanical properties.

Owner:HAINAN UNIVERSITY

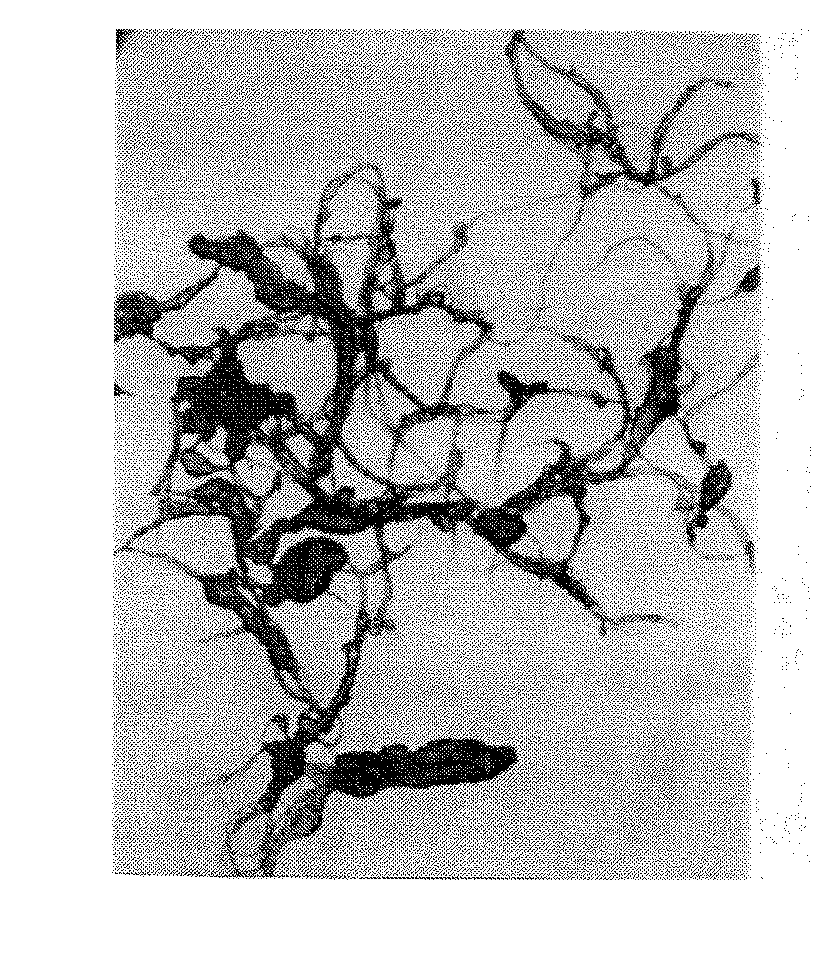

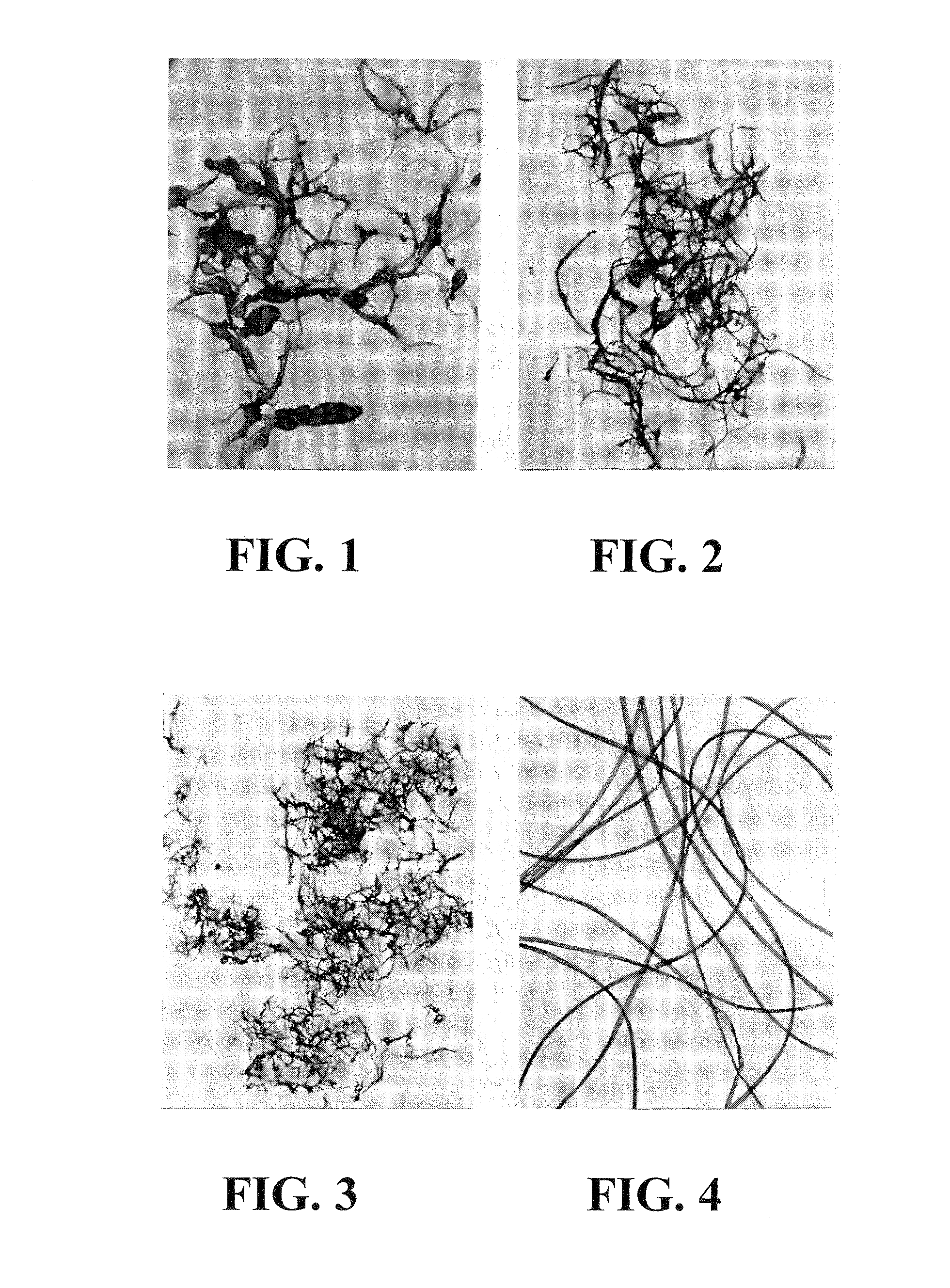

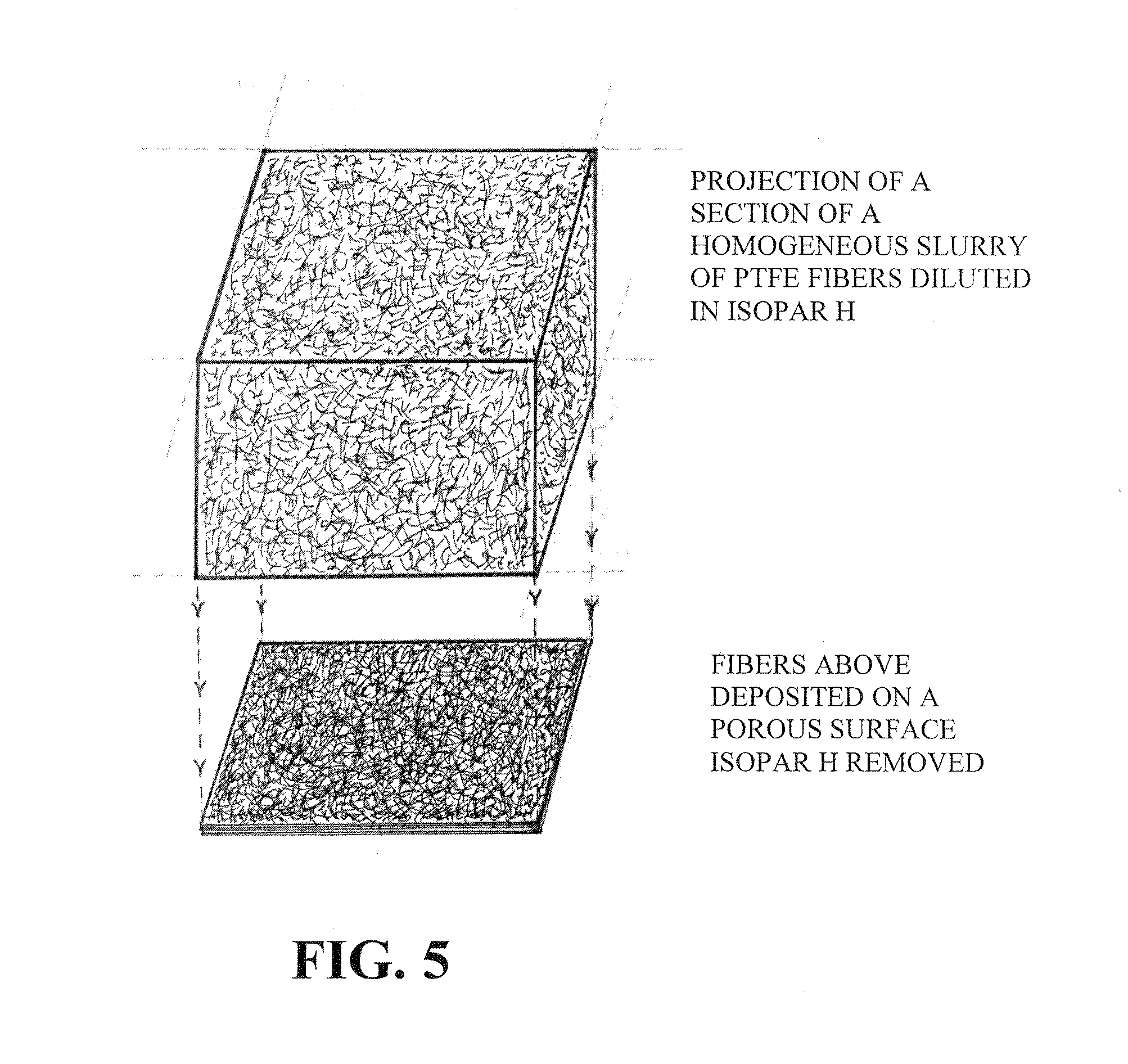

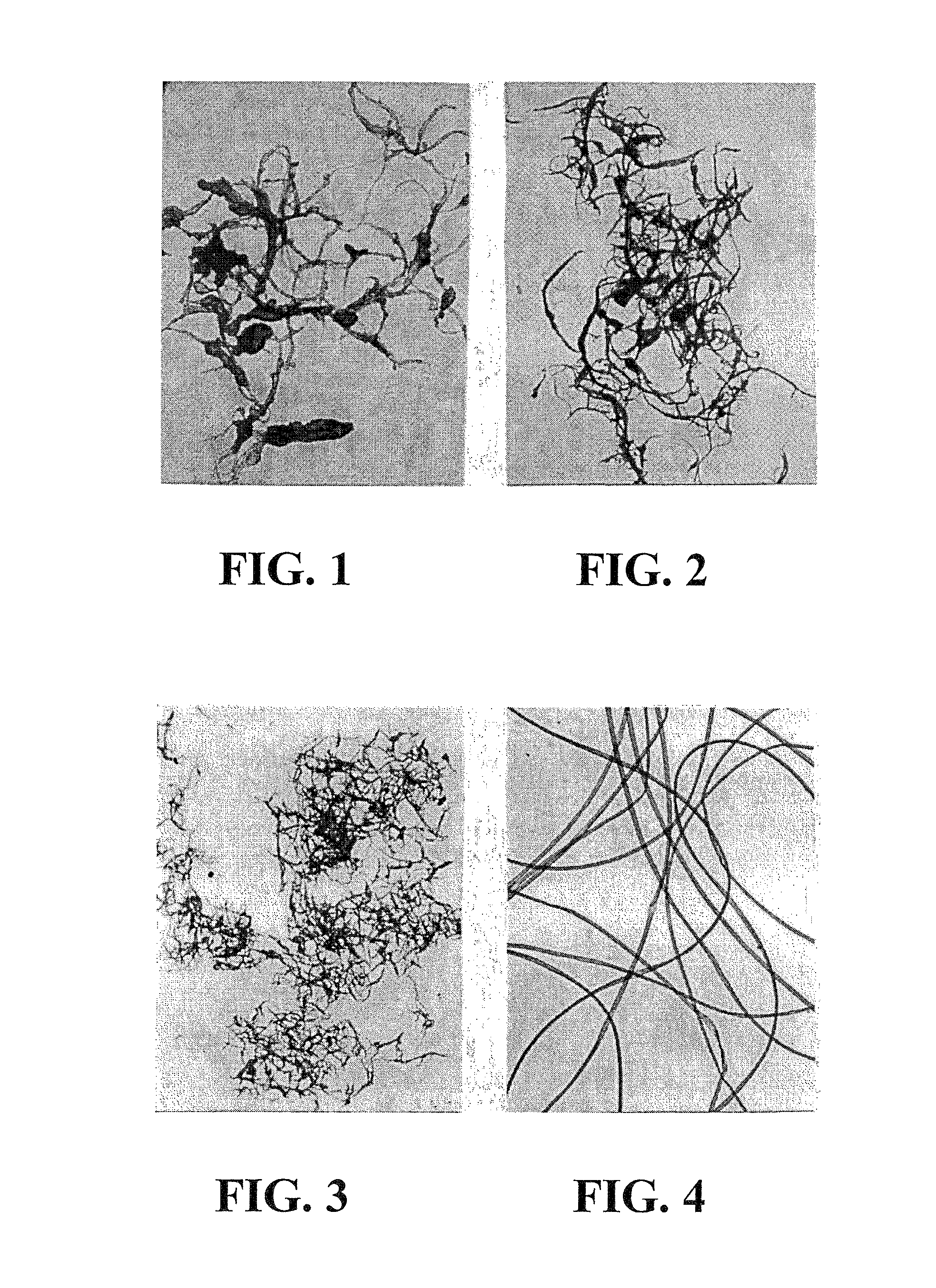

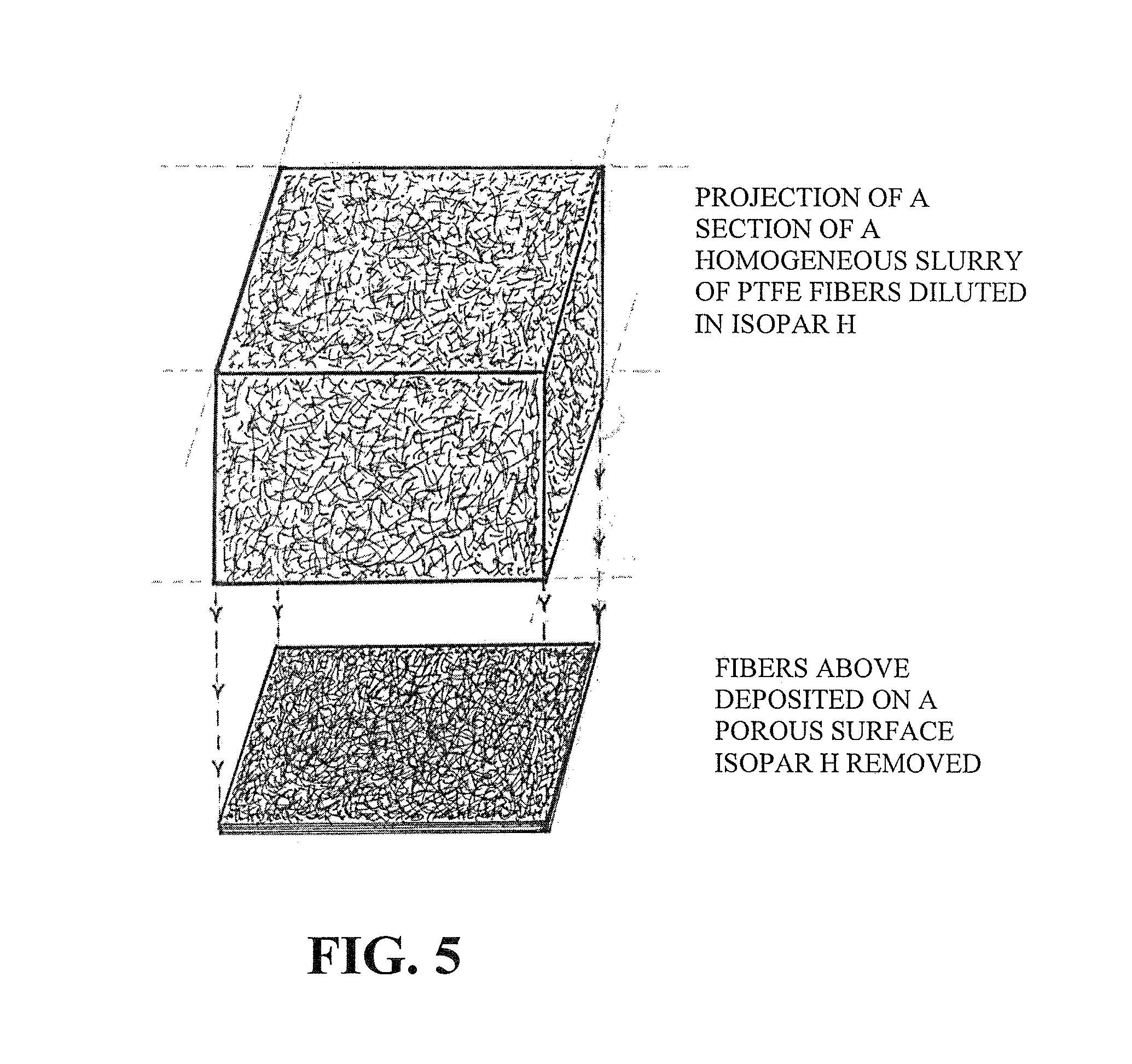

Isotropic NANO crystallites of polytetrafluoroethylene (PTFE) resin and products thereof that are biaxially planar oriented and form stable

The subject invention concerns the use of staple length nano polytetrafluoroethylene (PTFE) crystallites obtained by liquid shearing PTFE dispersion particles that are wet by a liquid with a surface tension below 30 dynes / cm this liquid will spread on PTFE resin surfaces and has a contact angle of zero (0) degrees with a PTFE surface. Staple length PTFE resin micro-fibers will form rapidly under high liquid shearing force at 125° C. when diluted 1 part PTFE resin to 20 parts liquid. The subject invention also includes the application of products that are multi-directional planar oriented and isotropic as sheet, membranes and structures useful for high performance filtering, fuel and solar cells and related energy applications. It also concerns products made from formulations as coatings and product for forming, shaping and molding sheet and structures of the subject invention and methods of adhering, bond and laminating components of these structures without adhesives.

Owner:ROBERTS FLORENCE

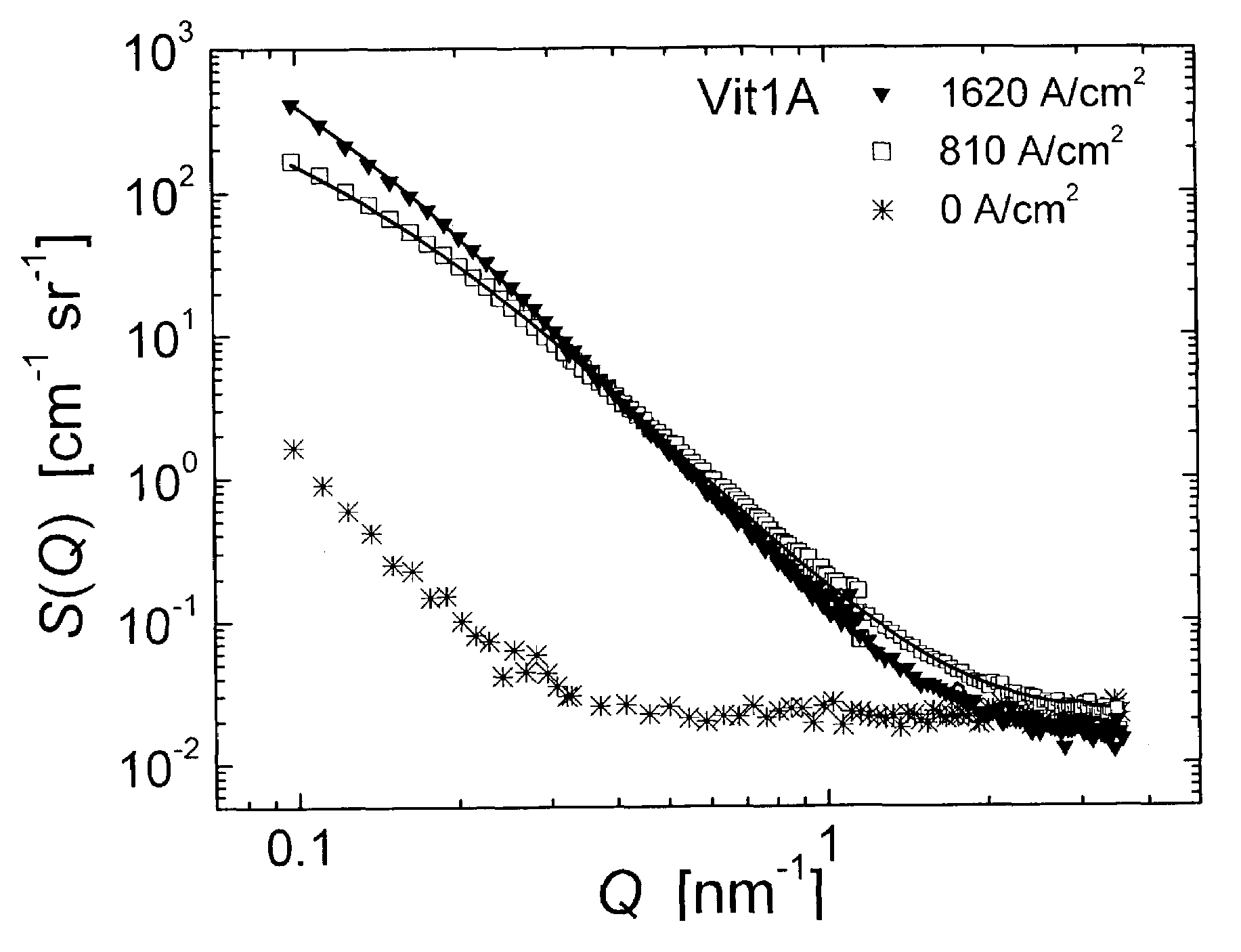

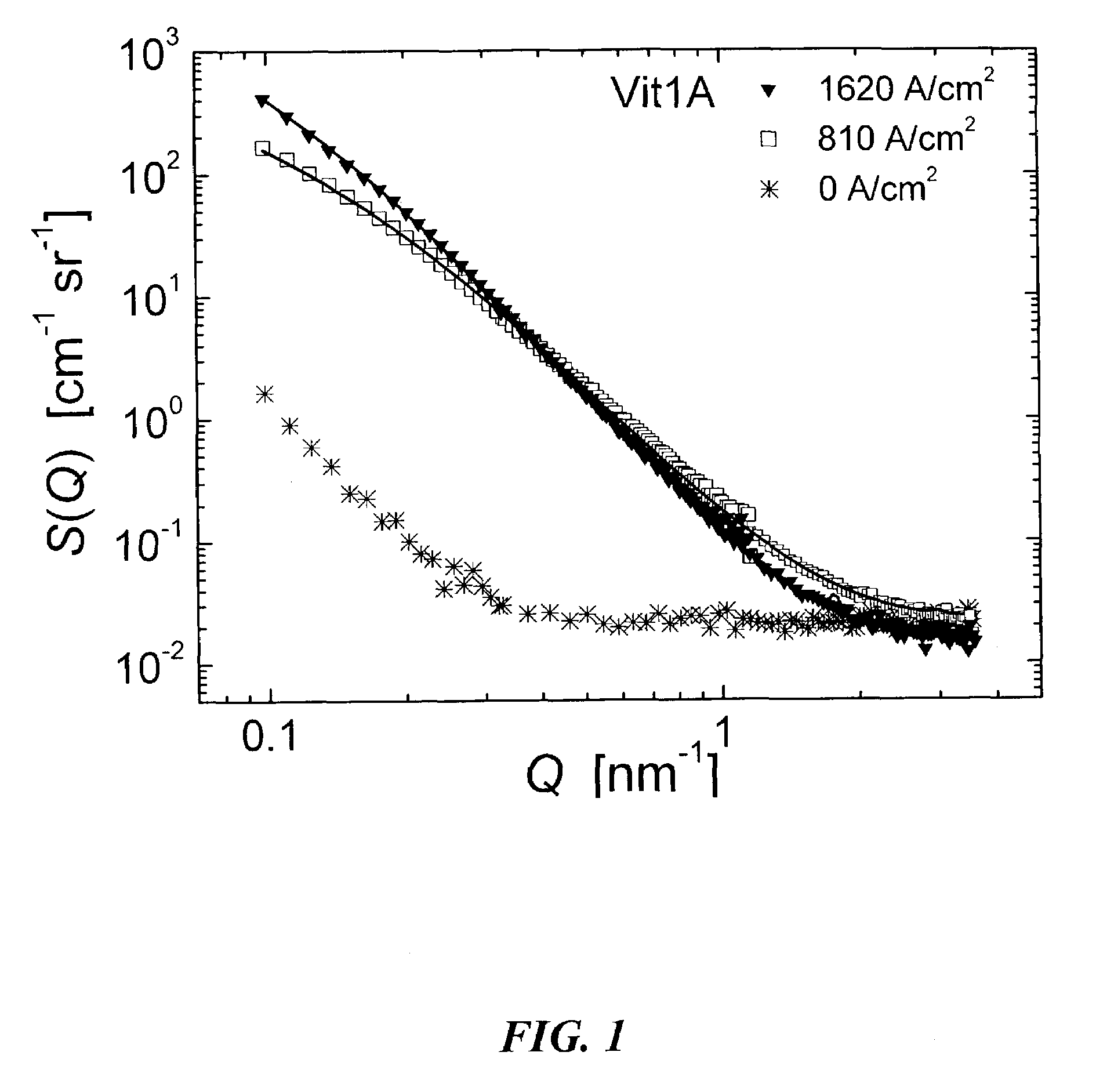

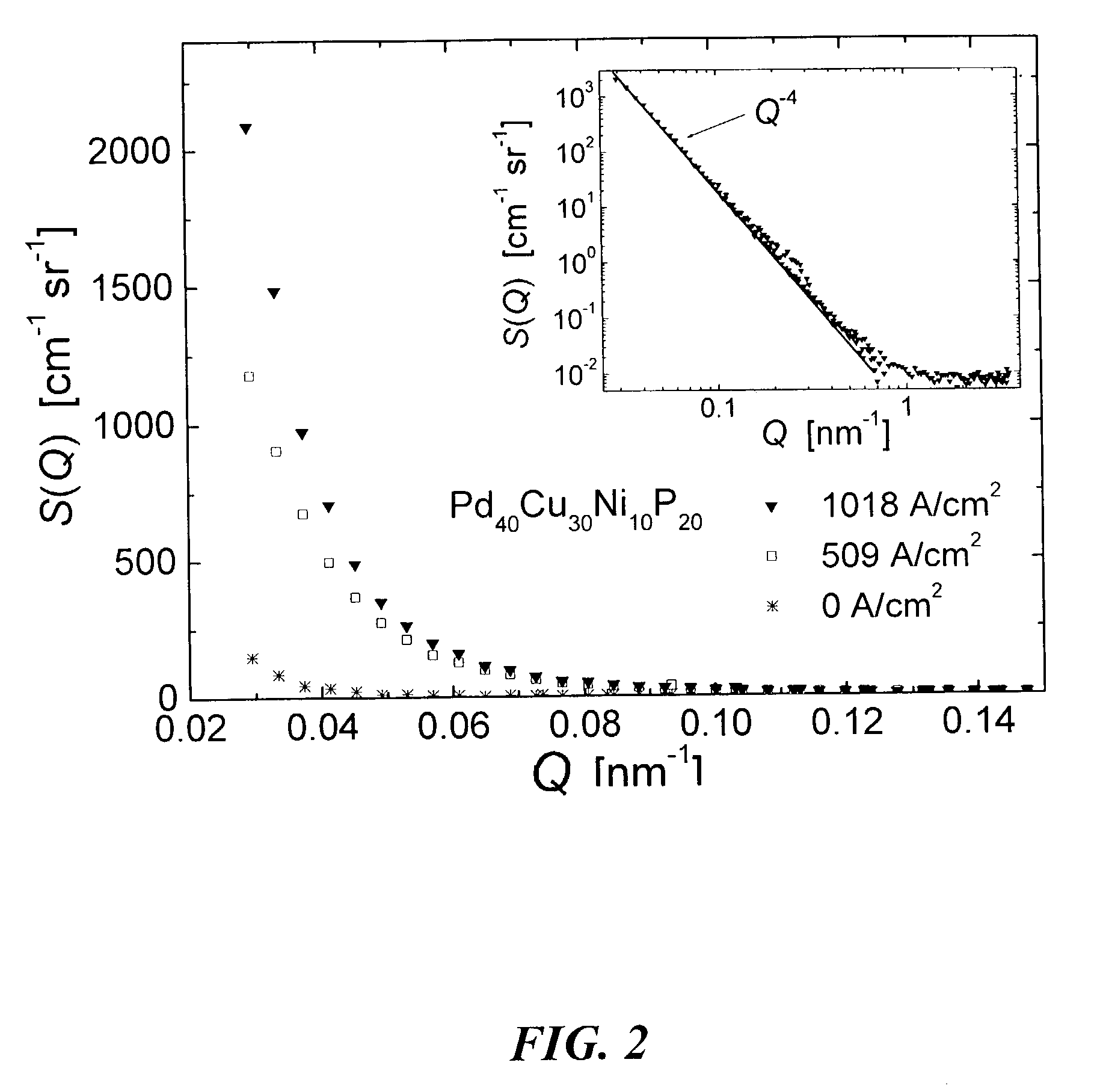

Metallic glasses with crystalline dispersions formed by electric currents

Owner:RGT UNIV OF CALIFORNIA

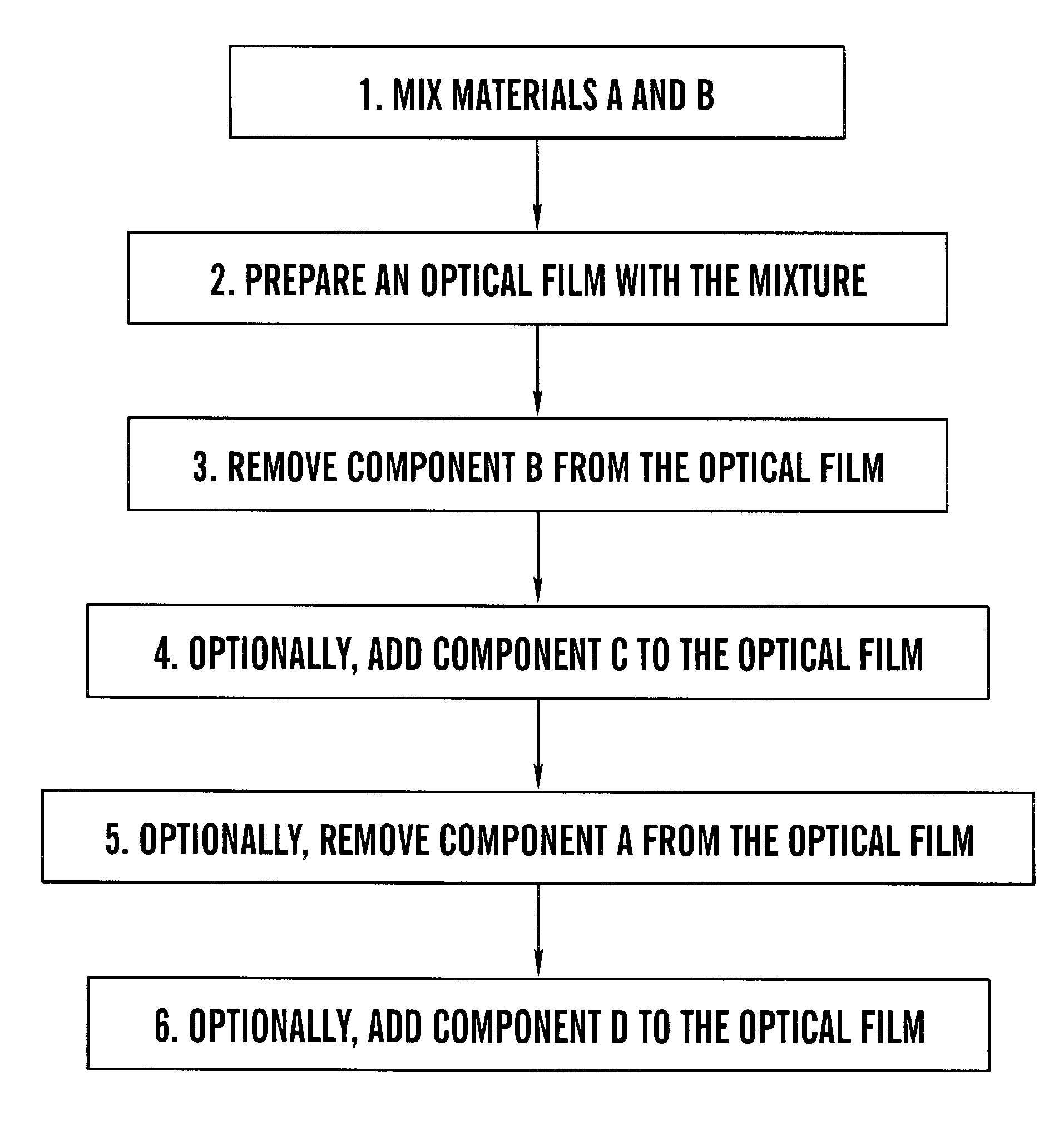

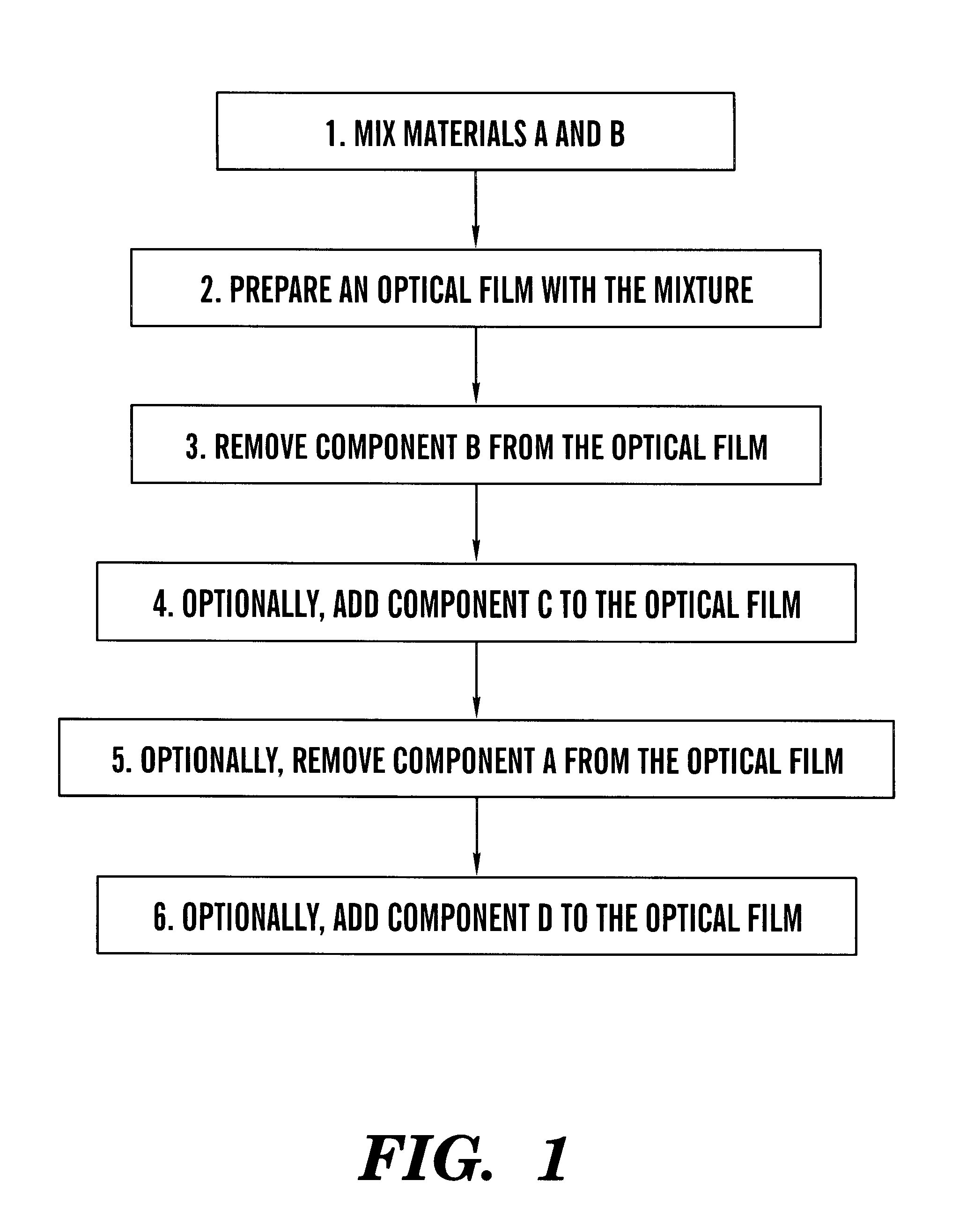

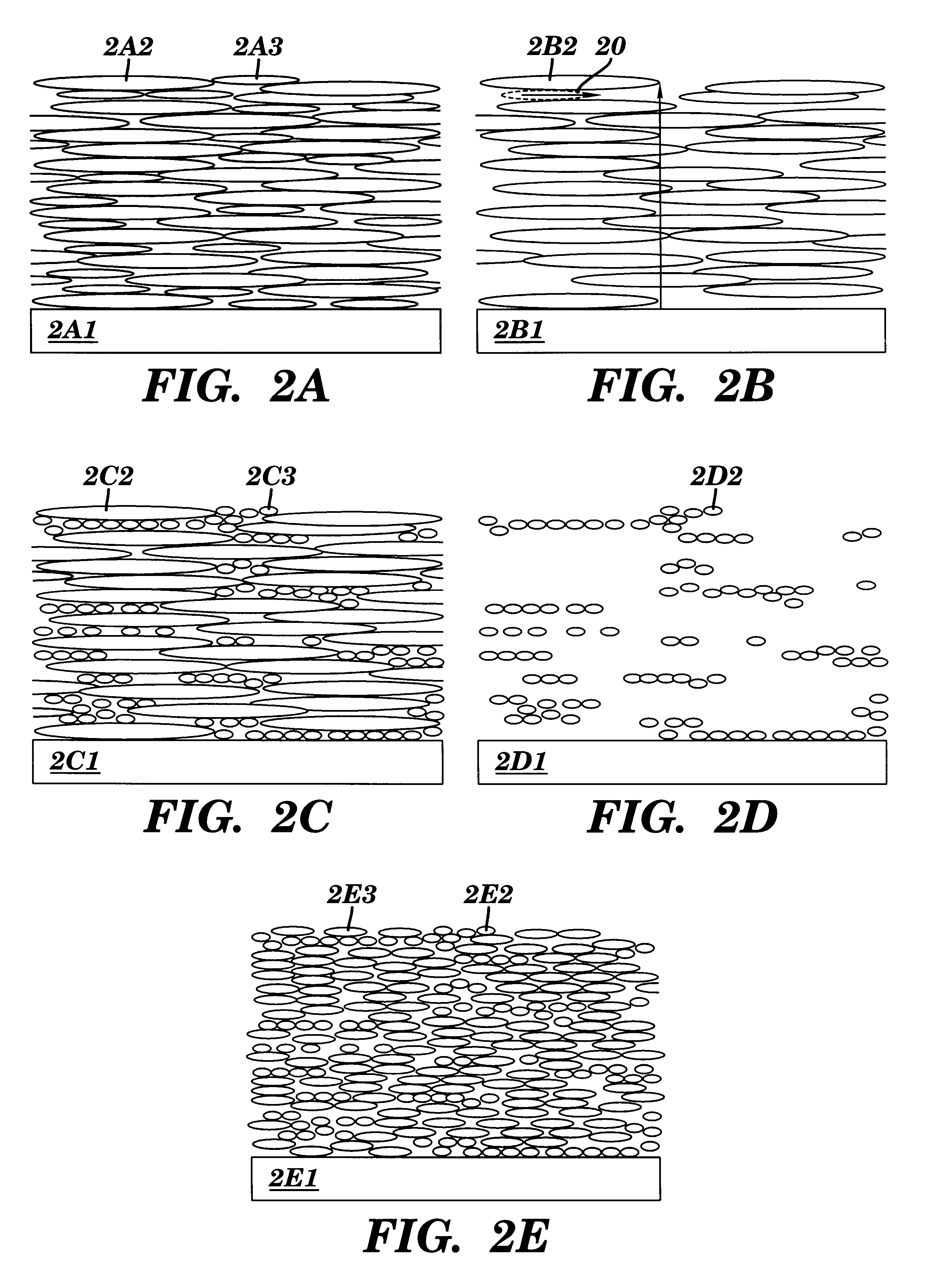

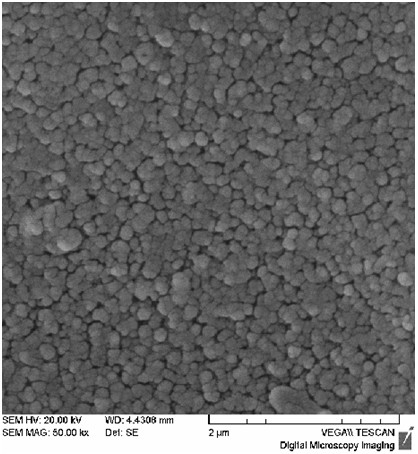

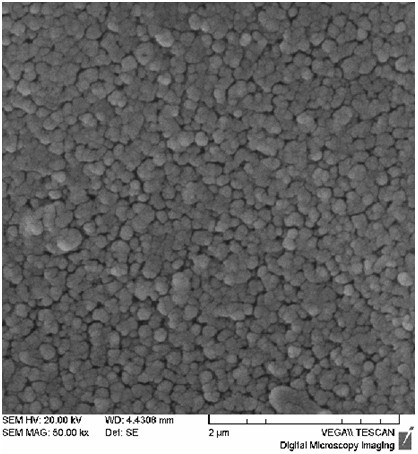

Composite nonlinear optical film, method of producing the same and applications of the same

A method is provided for fabricating composite nonlinear optical (NLO) organic films that are suited for use in NLO device applications. The highly NLO properties of these films arise from the vector alignment of "guest' NLO molecules in a self-ordered nano-structured liquid crystal "host' film. Field-poling is used to remove the centro-symmetry. The "guest' concentration is increased by film processing to incorporate oriented nonlinear nano-crystallites to increase nonlinearity. NLO devices based on such films are of low cost and permit fast switching in a compact device format.

Owner:REVEO

Method for preparing calcium aluminosilicate nanometer microcrystal glass by utilizing natrium silica calcium glass waste slag

InactiveCN101973709AIncreased crystallization tendencyImprove mechanical propertiesSlagSilicon oxide

The invention provides a method for preparing calcium aluminosilicate nanometer microcrystal glass by utilizing natrium silica calcium glass waste slag. The method comprises the following steps: 1) classifying, grinding and screening natrium silica calcium glass waste slag to prepare glass powder; 2) adding silicon dioxide, calcium oxide, aluminum oxide, boron oxide, TiO2 / P2O5 composite nucleating agent and rare-earth oxide to ensure that component requirement of the calcium aluminosilicate (CAS) microcrystal glass can be fulfilled; 3) filling the uniformly mixed glass materials into a high-alumina crucible, and pouring into a die to press and mold; and 4) putting the pressed glass plate in a muffle furnace for heat treatment, cooling to room temperature with the furnace after heat treatment to obtain the CAS nanometer microcrystal glass. The method has the advantages that: (1) the mechanical performance of the microcrystal glass is greatly improved; and (2) the additive dosage is adjusted according to the component composition of the glass residues to ensure that the glass achieves the regulated formula proportion. The method is suitable for the conventional various civil natrium silica calcium glass waste slag.

Owner:NANCHANG HANGKONG UNIVERSITY

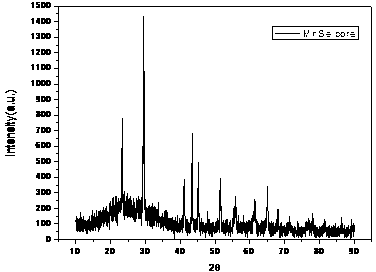

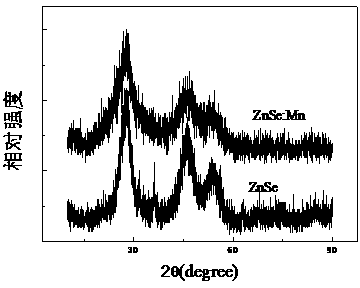

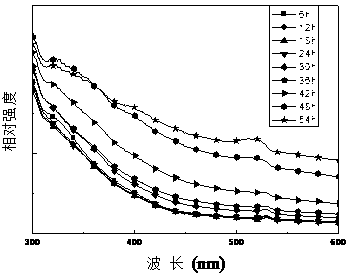

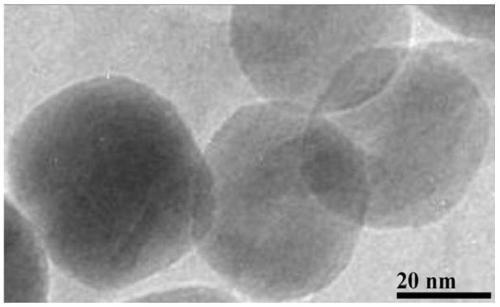

Nucleation water-phase preparation method of ZnSe:Mn quantum dots

InactiveCN103320134AGood dispersionImprove stabilityLuminescent compositionsMANGANESE ACETATEFluorescence

The invention relates to a nucleation water-phase preparation method of ZnSe:Mn quantum dots, belonging to the technical field of composite nano microcrystal materials. The inner core of the product is MnSe quantum dots, and the outer layer is ZnSe quantum dots. The preparation method comprises the following steps: reacting sodium borohydride (NaBH4) and selenium powder to prepare sodium hydrogen selenide (NaHSe), injecting the sodium hydrogen selenide into a manganese acetate / 3-mercaptopropionic acid solution of which the pH value is regulated by sodium hydroxide so as to react to generate a MnSe quantum dot solution, and adding a zinc acetate / 3-mercaptopropionic acid solution of which the pH value is regulated by sodium hydroxide into the MnSe quantum dot solution to form ZnSe:Mn quantum dots. The product obtained by the method provided by the invention has the advantages of uniform dispersion, high stability and less aggregation, and can be used in the fields of biological fluorescence labeling, drug isolation and some photoelectric devices.

Owner:SHANGHAI UNIV

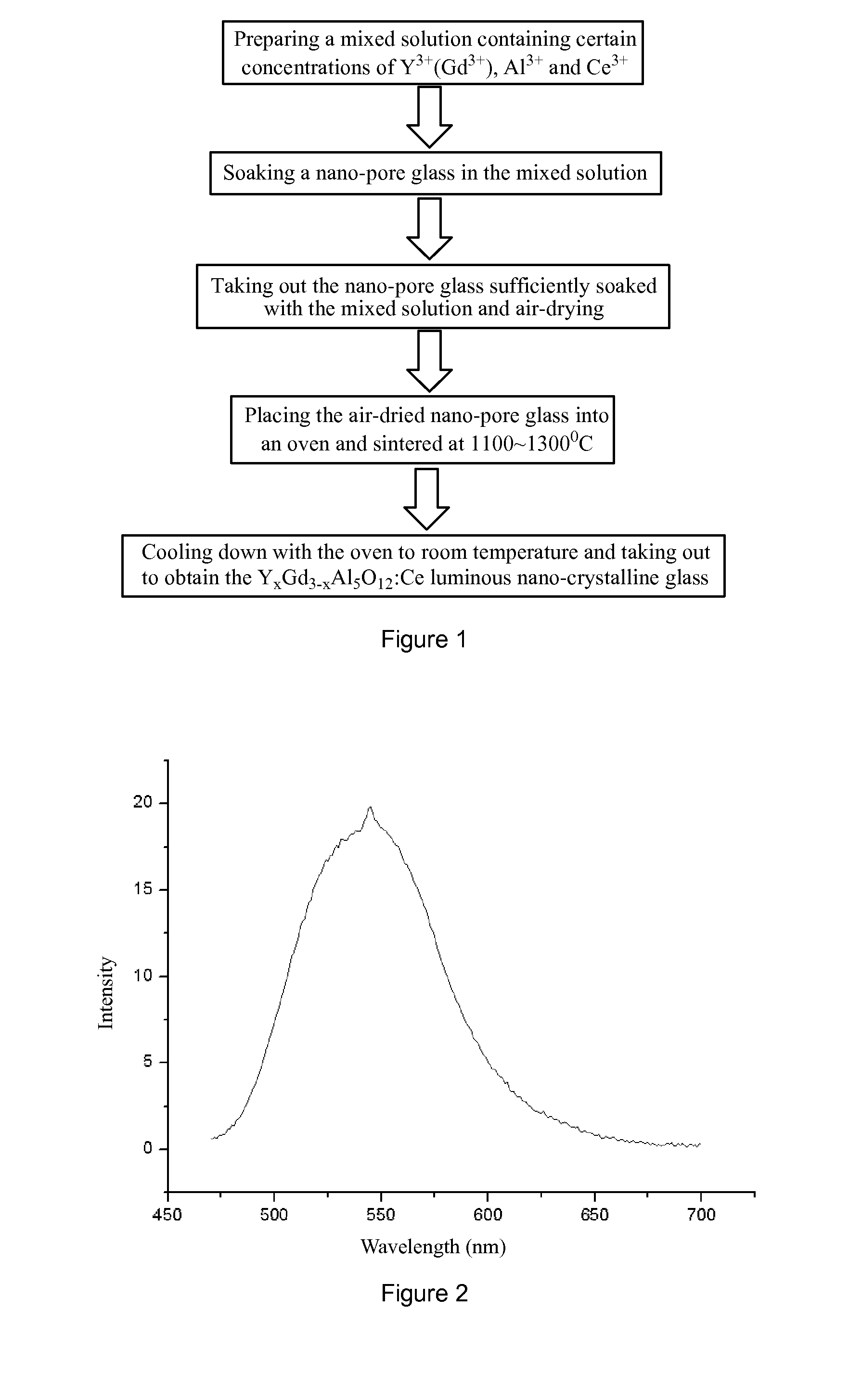

Luminous nano-glass-ceramics used as white LED source and preparing method of luminous nano-glass-ceramics

A luminous nano-glass-ceramics used as white LED source and the preparing method of nano-glass-ceramics are provided. The glass is a kind of non-porous compact SiO2 glass in which luminous nano-microcrystalites are dispersed. The luminous nano-microcrystalite has the chemical formula of YxGd3-xAl5O12:Ce, wherein 0≦x≦3. The stability of the said glass is good and its irradiance is uniform. The preparing method comprises the following steps: dissolving the compound raw materials in the solvent to form mixed solution, dipping the nano-microporous SiO2 glass in the solution, taking it out and air drying, sintering at the temperature of 1100-1300° C. for 1-5 hours by stage heating, and obtaining the product. The method has a simple process, convenient operation and low cost.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Nonvolatile charge capture type storage device, preparation method thereof and application

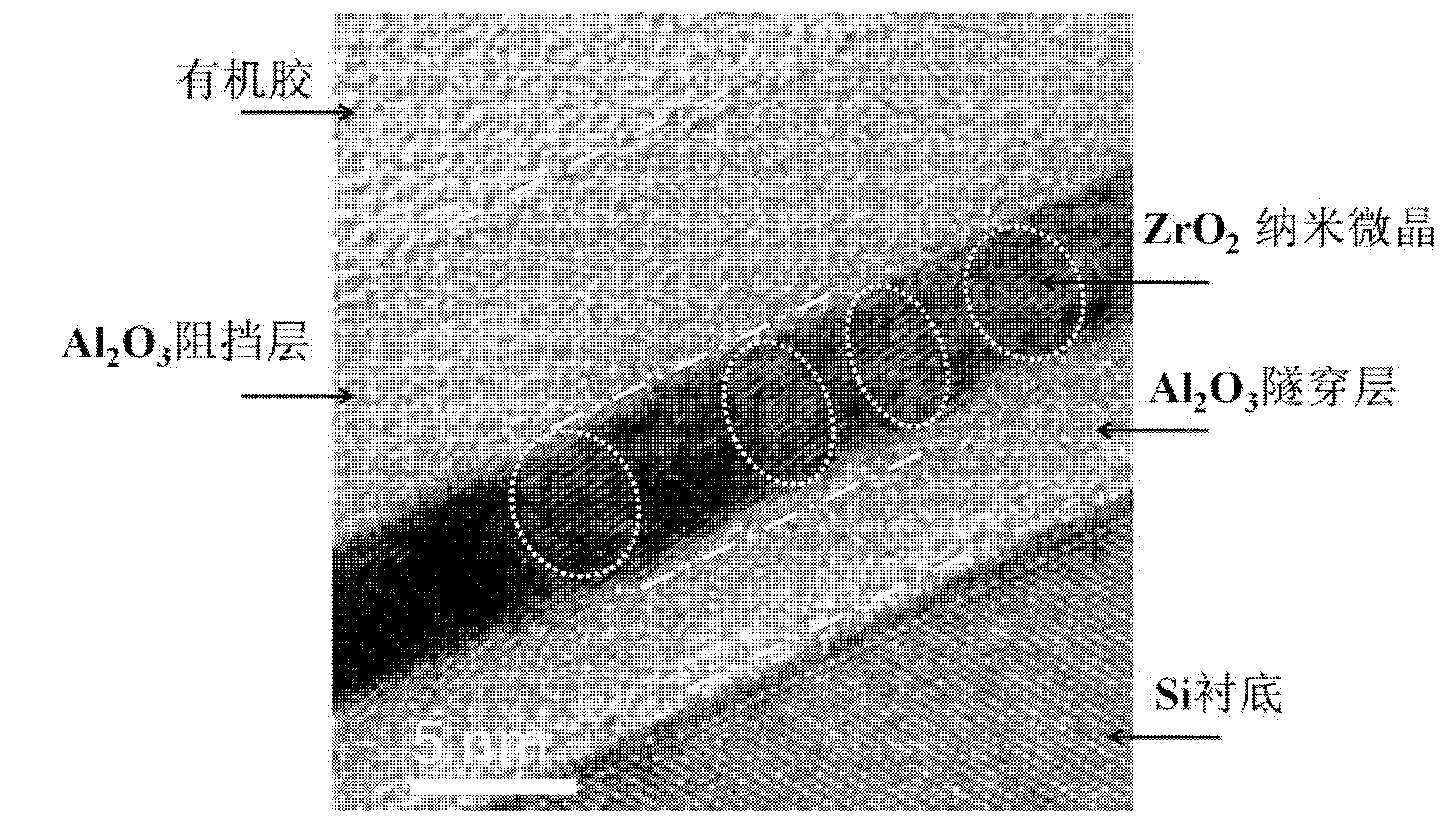

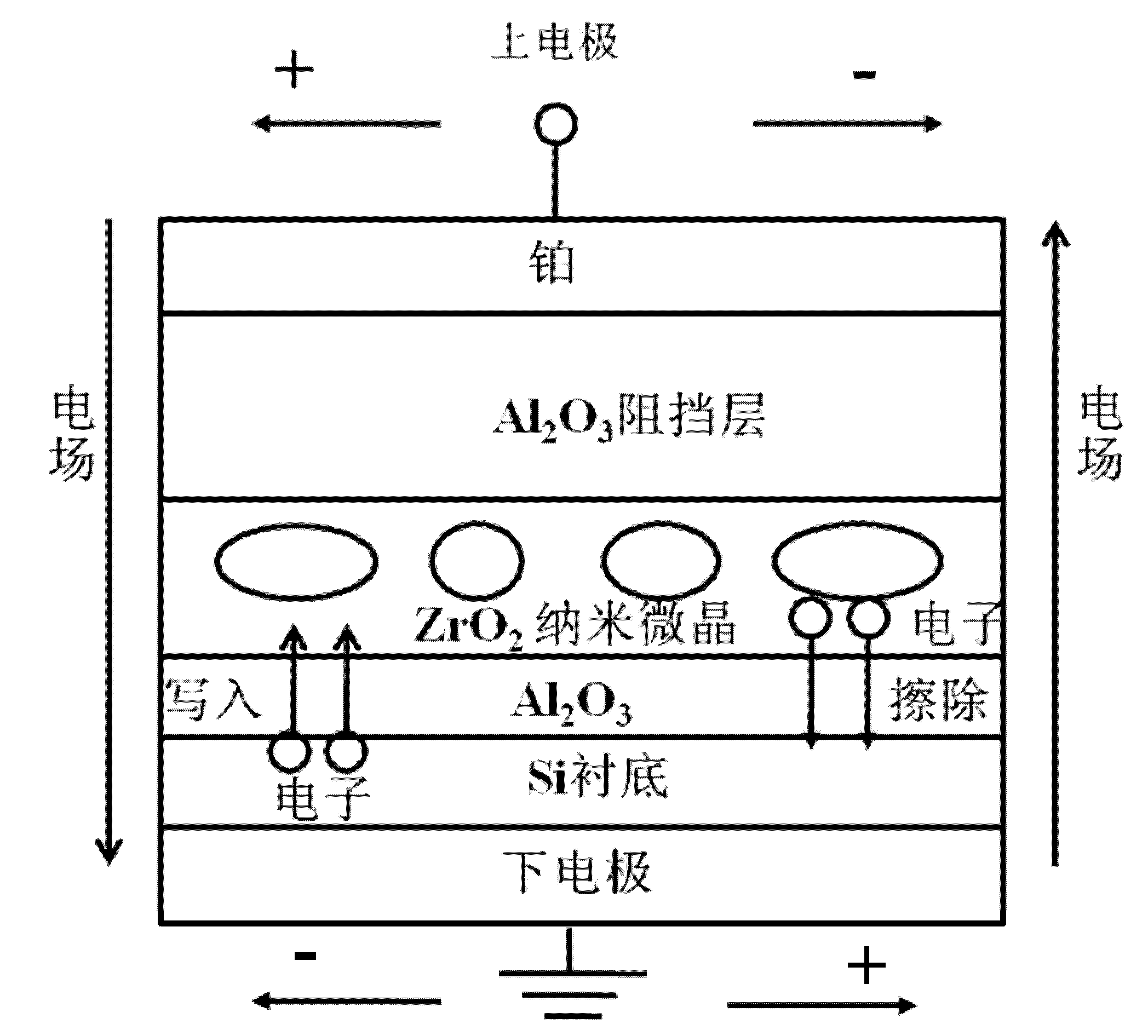

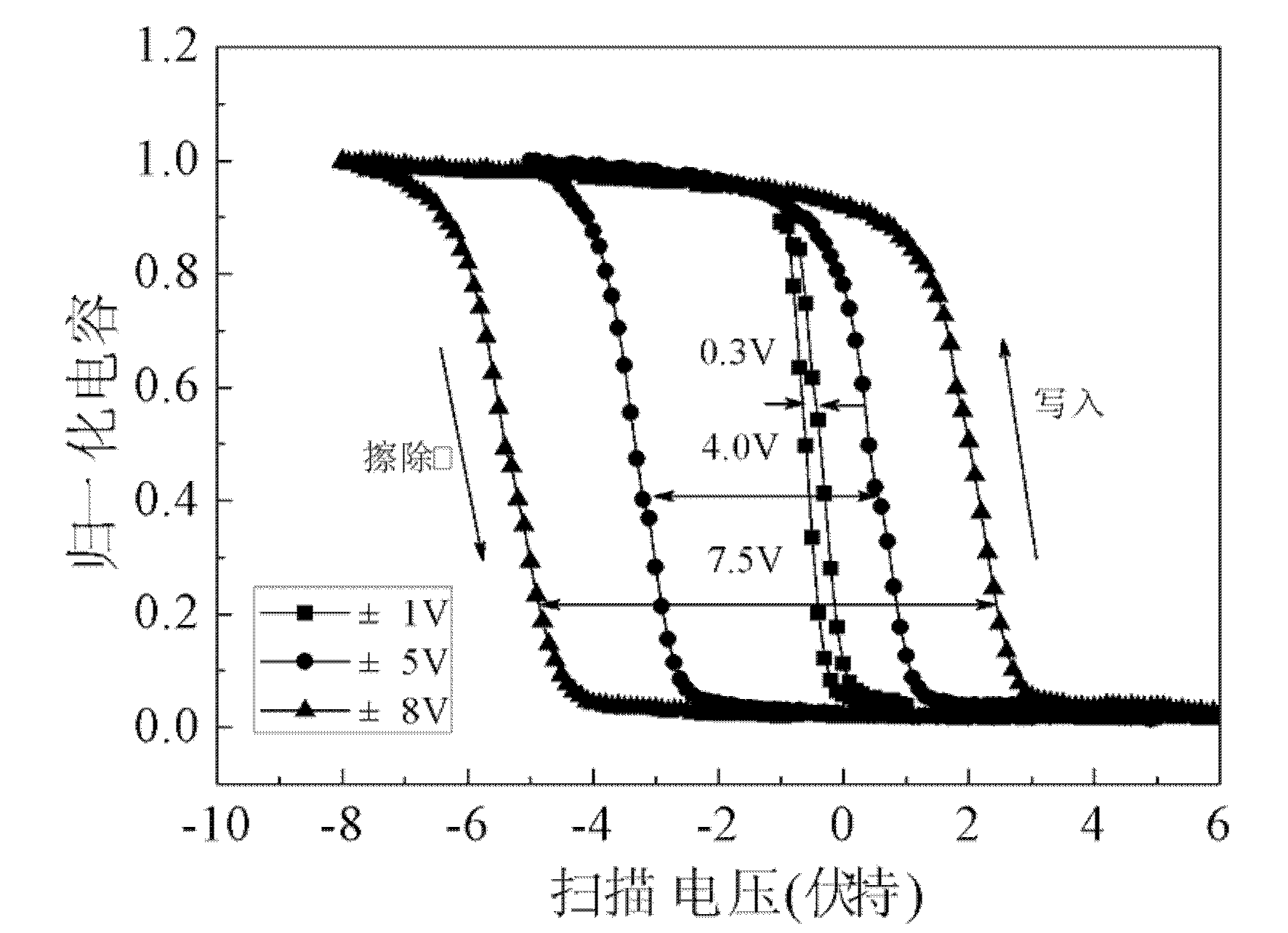

InactiveCN102208346ALarge amount of stored informationApparent hysteresis windowNanoinformaticsVacuum evaporation coatingComputer scienceNanometre

The invention relates to a nonvolatile charge capture type storage device, a preparation method thereof and application. The preparation method is characterized by simple operation and easy control. The nanometer microcrystalline as a storage medium has a uniform distribution in the storage device obtained. The preparation method of the nonvolatile charge capture type storage device comprises thefollowing steps: a) forming a tunneling layer on the substrate surface; 2) forming a uniform (ZrO2) x (M) 1- x film as an accumulation layer on the tunneling layer, wherein x is larger than 0.5 and less than 1 and the M is SiO2 or Al2O3; c) forming a barrier layer on the accumulation layer; d) annealing the sample prepared and precipitating the ZrO2 nanometer microcrystalline from the accumulation layer to be the storage medium. According to the invention, a means of high temperature annealing processing is used to precipitate the ZrO2 nanometer microcrystalline from the accumulation layer parent phase, thereby realizing an effect of nanometer microcrystalline storage. According to the method, the nanometer microcrystalline obtained as the storage medium has a uniform distribution in the amorphous parent phase.

Owner:NANJING UNIV

Crystalline metallic nano-particles and colloids thereof

InactiveUS20090236569A1Soften fastBetter and more effectiveMaterial nanotechnologyIndividual molecule manipulationNanoparticleAlloy

Owner:NANO TECH GRP

Preparation technique for thermal spraying nano-microcrystalline enamel

InactiveCN105463457AImprove corrosion resistanceDense coatingMolten spray coatingThermal sprayingFrit

The invention relates to a preparation technique for thermal spraying nano-microcrystalline enamel. The process comprises the steps that 1, an enamel glaze block is prepared, specifically, a raw material prepared according to a formula and mixed uniformly is fed into a high-temperature furnace to be melted sufficiently at the temperature of 1300-1500 DEG C and is subjected to water quenching to obtain the homogeneous enamel melted glaze block; 2, thermal spraying powder is prepared, specifically, the melted glaze block is smashed and ground, enamel pre-grinding powder is obtained, 5-30% of nano-silica is added into the pre-grinding powder, mixing granulation is carried out, and the nano-microcrystalline enamel powder for thermal spraying is obtained; and 3, thermal spraying and overall crystallization are conducted, specifically, the enamel powder is uniformly sprayed on the surface of a workpiece through a thermal spraying gun, and the powder is melted and liquefied in the process of being spayed out from the spraying gun and is cooled and solidified after being sprayed on the surface of the workpiece; the obtained enamel layer is a multiphase composite material with nanocrystallines, microlite and glass being interwoven together. The enamel layer has the characteristics of being good in corrosion resistance, high in density, good in toughness, high in impact resistance, capable of being formed at a time and low in manufacturing cost.

Owner:李训竹

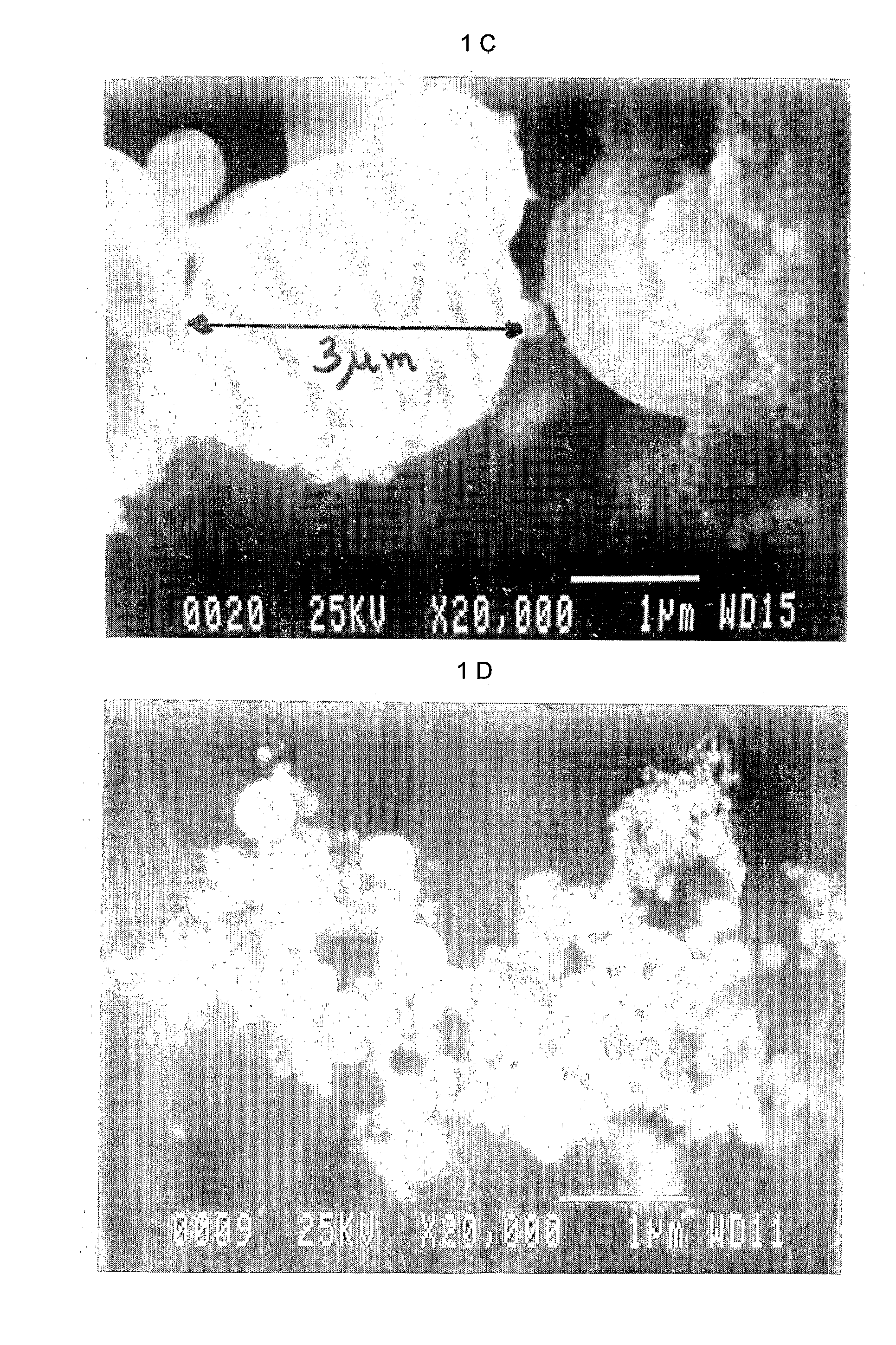

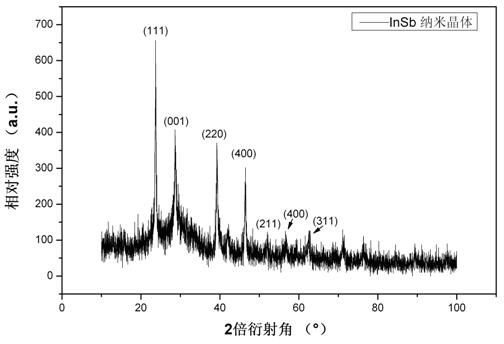

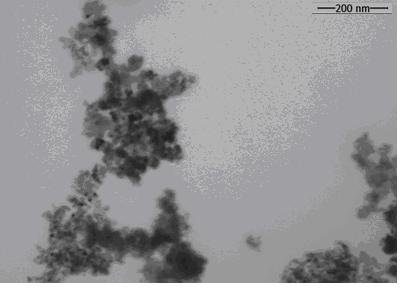

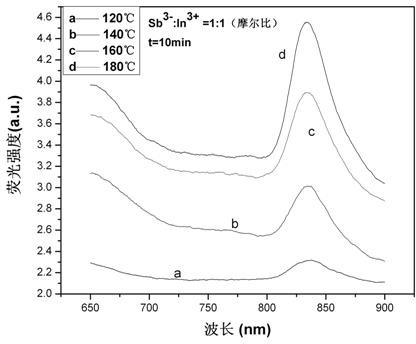

Preparation method of indium antimonide nanocrystal

InactiveCN102154705AStable in natureUniform particlesPolycrystalline material growthFrom normal temperature solutionsPtru catalystPolyethylene glycol

The invention relates to a preparation method of an indium antimonide nanocrystal, belonging to the technical field of a composite nanocrystal material. The product of the preparation method is the indium antimonide nanocrystal. The preparation method of the indium antimonide nanocrystal comprises steps of: mixing Sb2O3, In(NO3)3.9 / 2H2O, PEG200 (polyethylene glycol) with ethanediol in a 250ml three-necked flask, wherein the mixture is taken as growth solution; dissolving NaBH4 into ethidene diamine to be taken as storage solution; performing the oil bath on the growth solution until the temperature of the solution is 140 DEG C under the protective atmosphere of the nitrogen, and keeping the magnetic stirring for 30 minutes; adjusting the oil bath temperature at reaction temperature (120 DEG C-180 DEG C); fast injecting the storage solution into the growth solution (-2S) by a needle cylinder, and keeping the oil bath temperature and the magnetic stirring; sampling reaction solution within the reaction time from 5 minutes to 5 hours; and adding the alcohol with proper amount into the sampled reaction solution, and centrifuging for 20 minutes at the rotation speed of 15000rpm to separate the product (InSb). The preparation method is a liquid phase preparation method for preparing the InSb nanocrystal at a lower temperature (120-180 DEG C), wherein the method is high-efficiency, low-priced, free of catalytic agent and relatively safe; the prepared product is stable in property, and even in particle; and the preparation method can be used for providing the indium antimonide nanocrystal which is suitable for a high-speed electronic component, a magnetic component, and a far infrared-waveband photoelectric component.

Owner:SHANGHAI UNIV

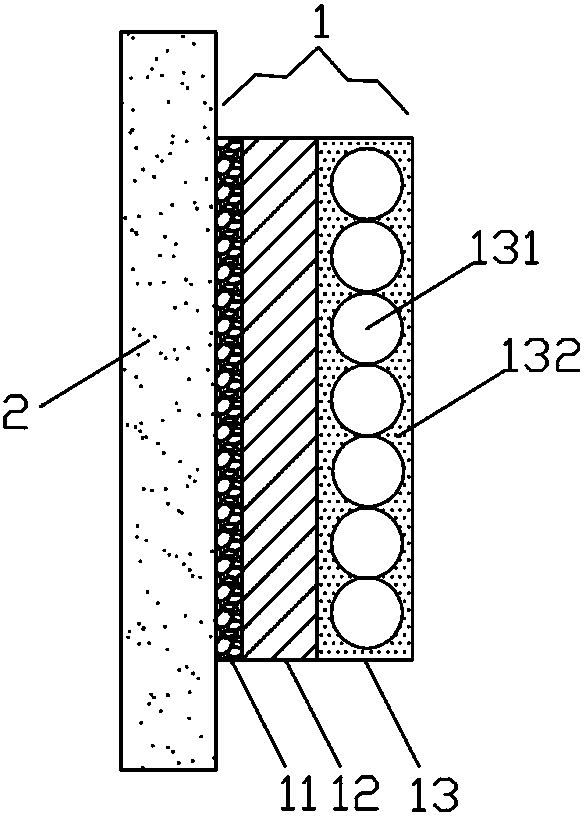

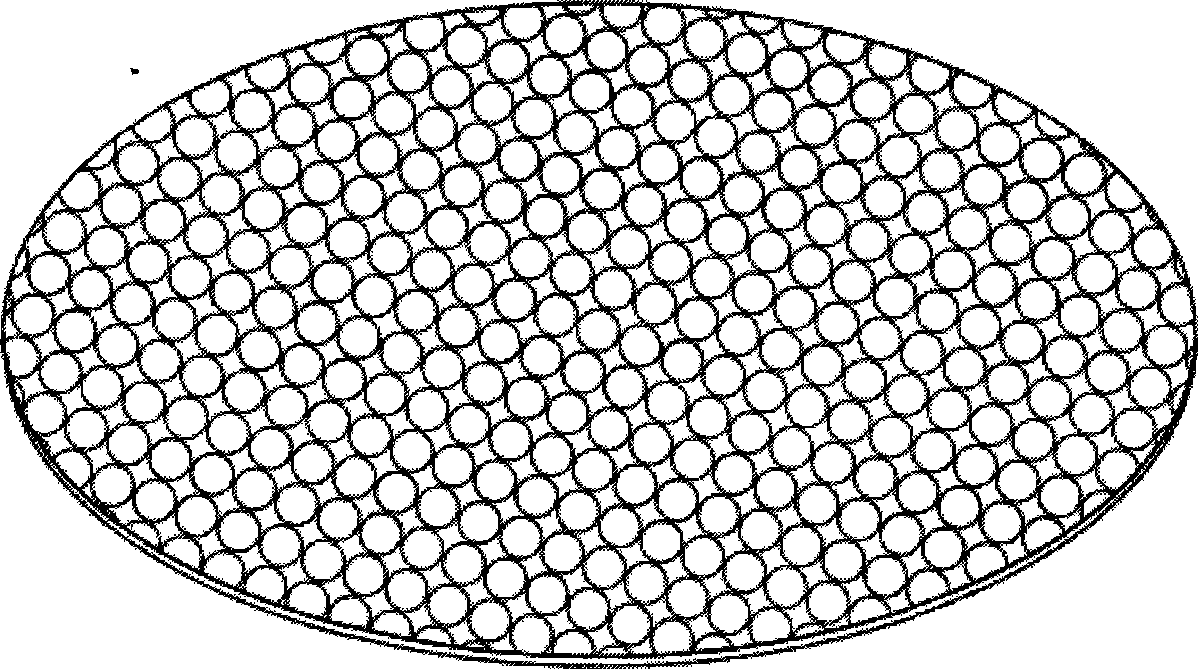

Nanometer microcrystal mixed optical structure back projection high-definition image film and back projection screen

The invention discloses a nanometer microcrystal mixed optical structure back projection high-definition image film. The nanometer microcrystal mixed optical structure back projection high-definitionimage film comprises a substrate layer, a nanometer microcrystal and nanometer micro ball mixed imaging coating layer and a back adhesive layer; the nanometer microcrystal and nanometer micro ball mixed imaging coating layer is formed by uniformly coating one surface of the substrate layer with nanometer microcrystal, nanometer micro balls and an adhesive based on a proportion; and the back adhesive layer is arranged on the other surface of the substrate layer for pasting external supports. The nanometer microcrystal and the nanometer micro balls are mixed and coated on the substrate layer, sothat compared with an image film with separated inorganic silicon particle coating layer and glass micro ball coating layer, the image film disclosed in the invention can eliminate projector light source light spots in a more all-around manner, the image angle of visibility can be enlarged to 178 degrees, and brightness, color saturation degree and light resistance and eye protection performanceof the projection image are improved, so that the image film is applicable to all projectors of different lenses on the market.

Owner:中科宝溢视觉科技(江苏)有限公司

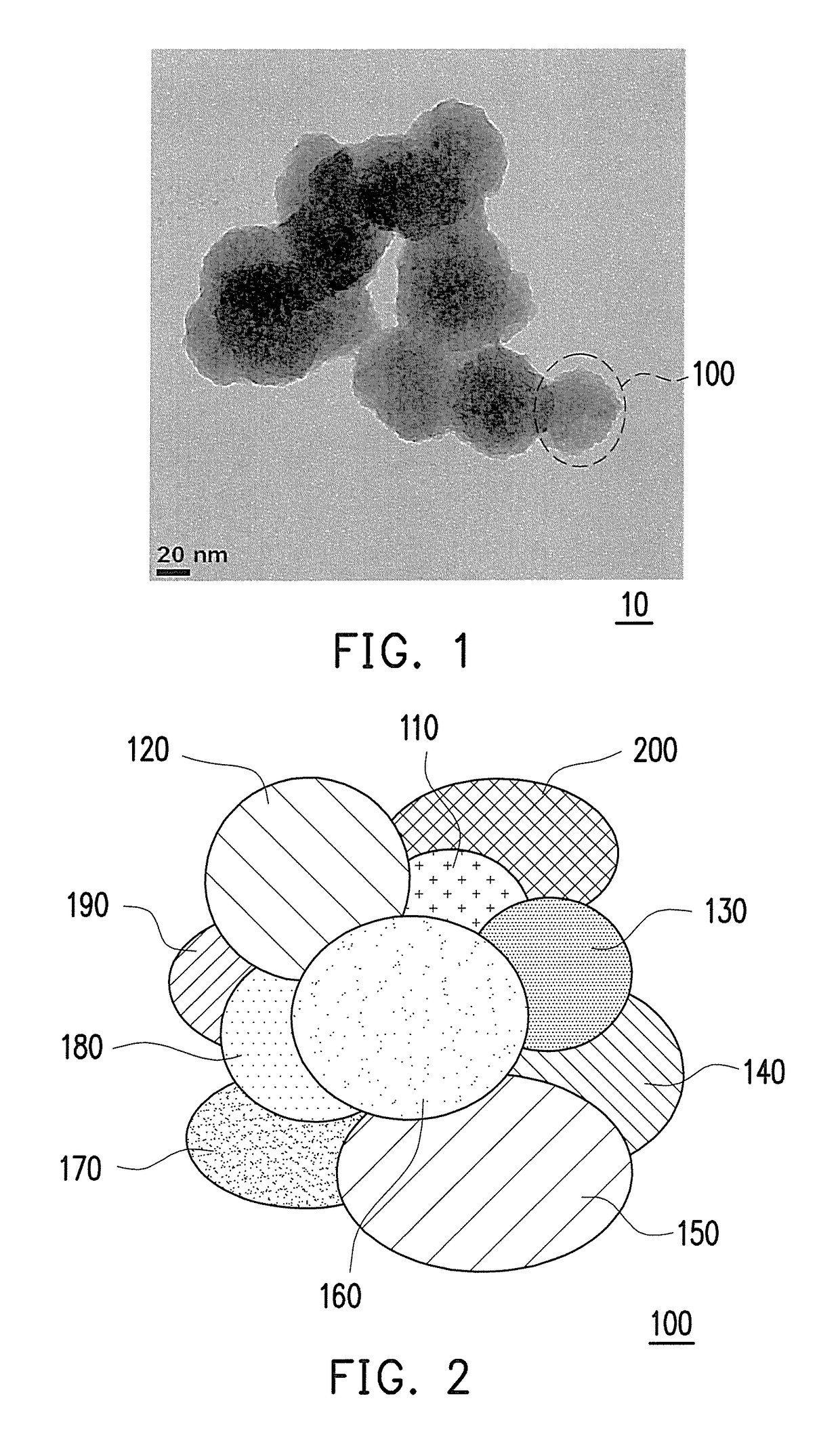

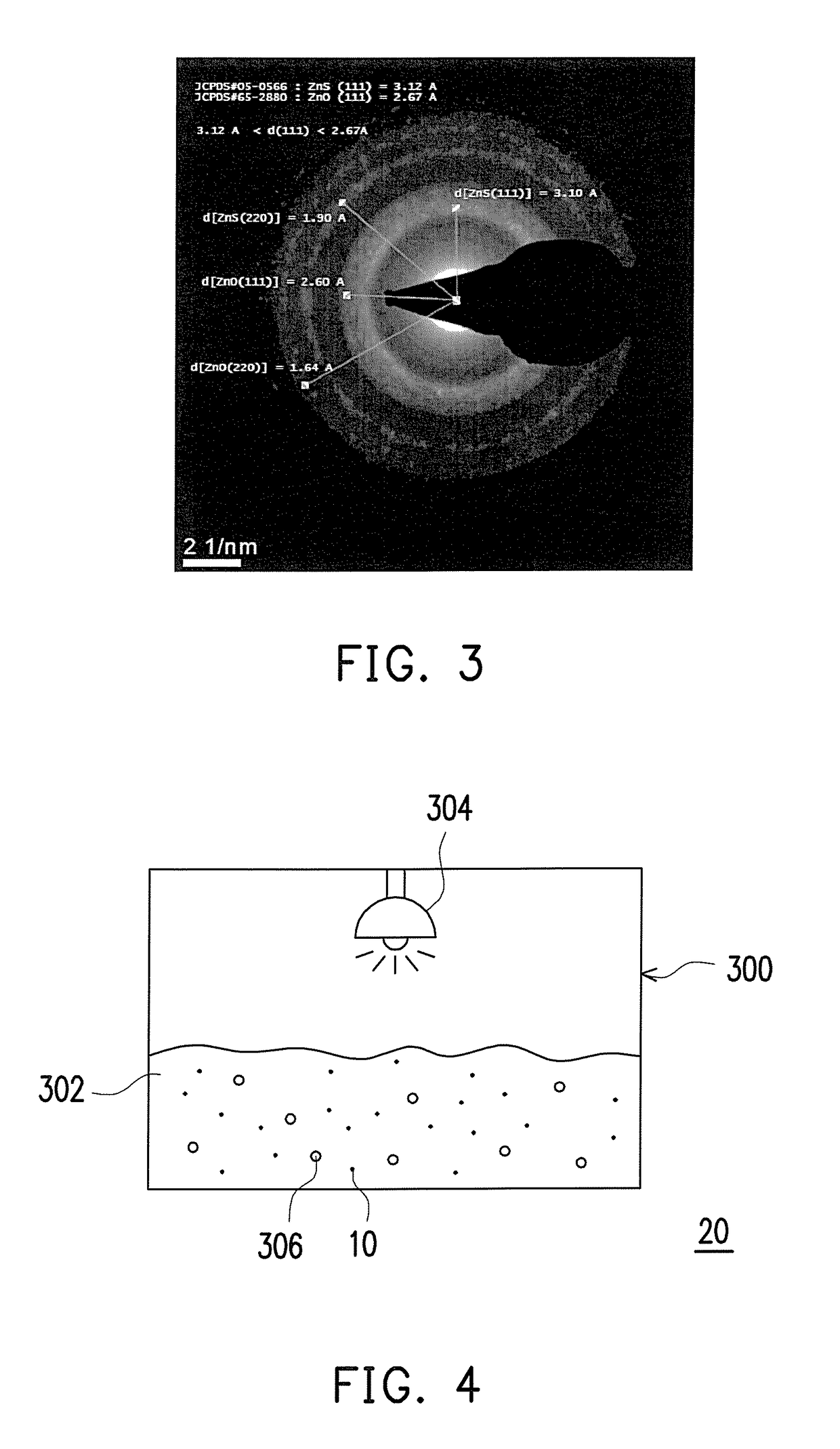

Photocatalyst powder and hydrogen producing system

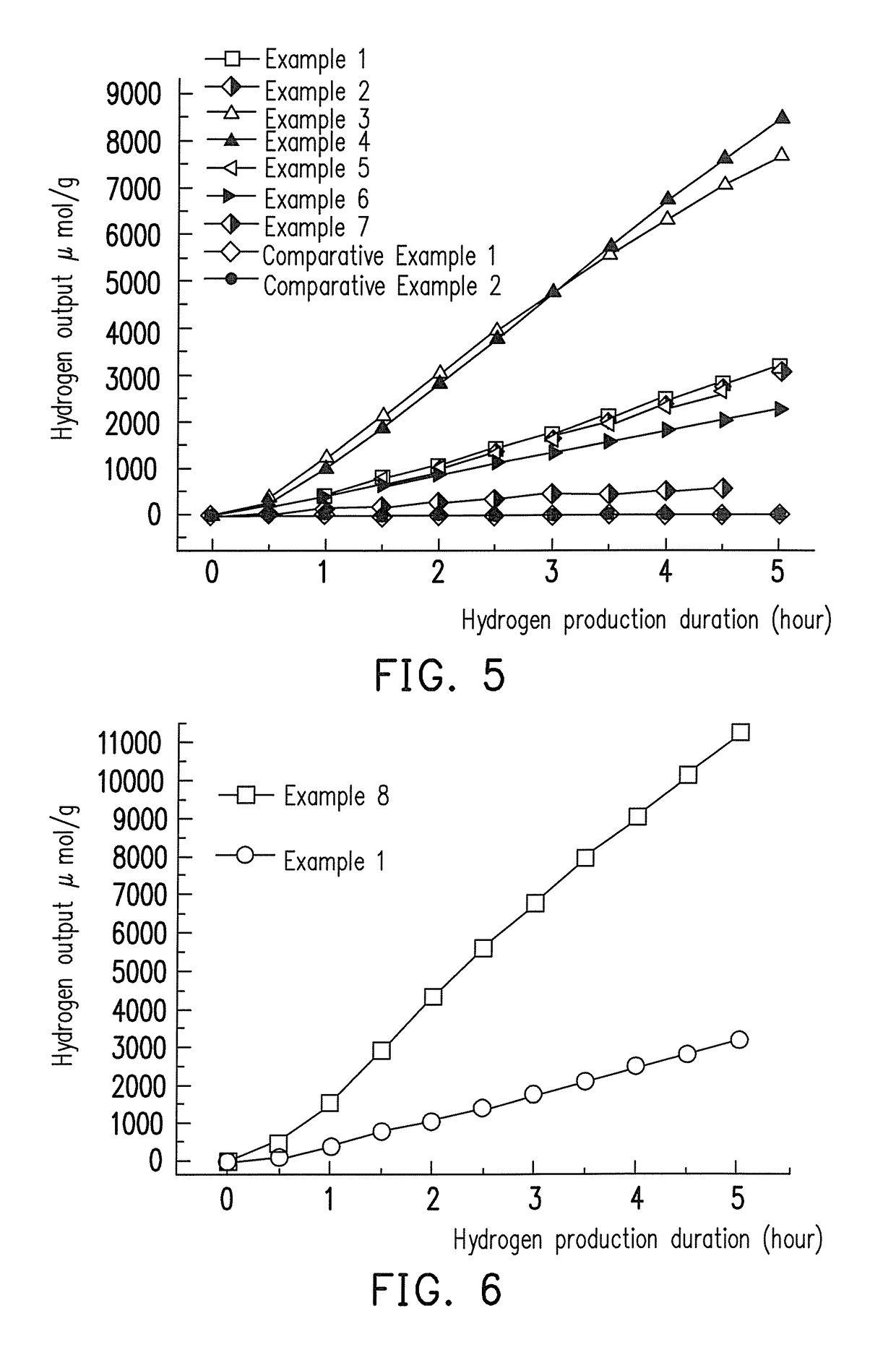

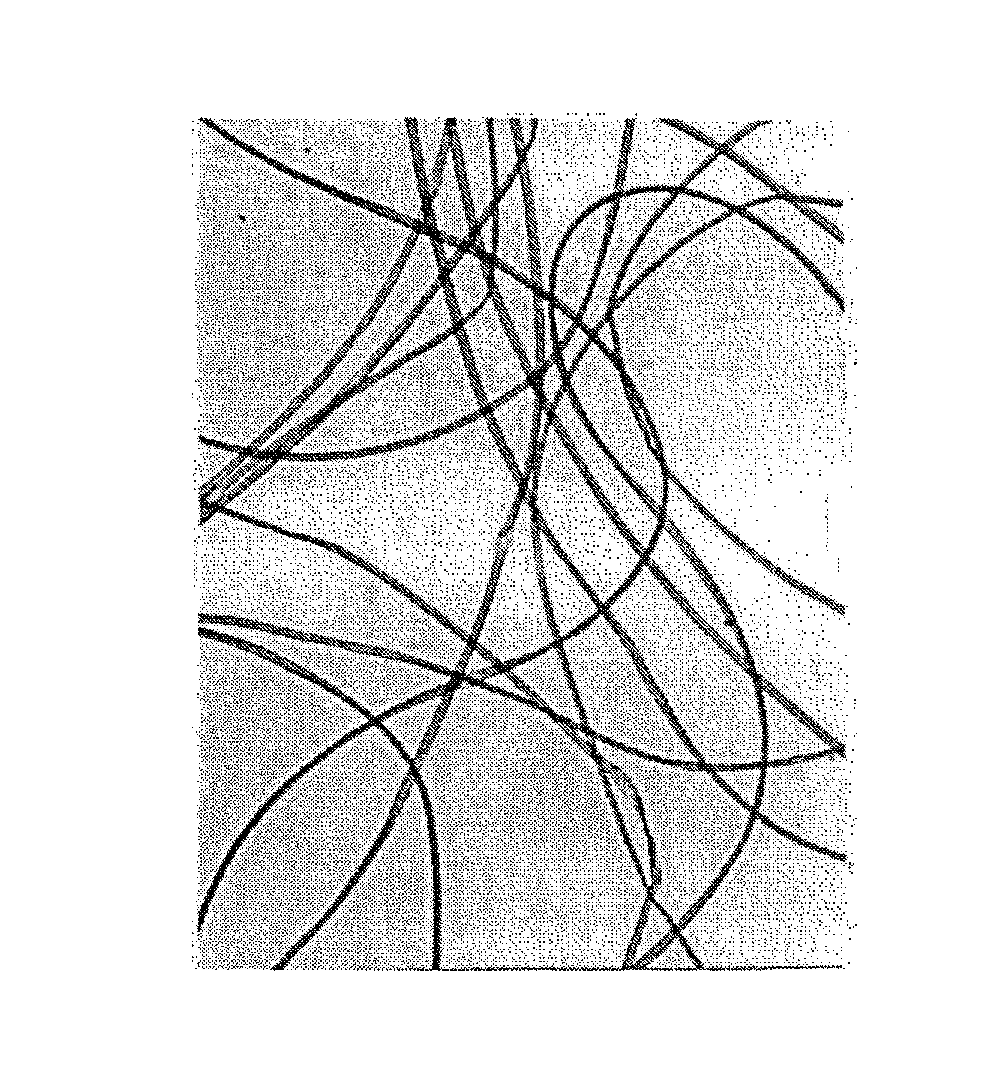

InactiveUS20170225153A1Improve hydrogen production efficiencyExtended service lifeCatalyst activation/preparationHydrogen productionHydrogenSingle crystal

A photocatalyst powder is provided. The photocatalyst powder includes a plurality of nano crystallite aggregates formed by a plurality of nano crystallites. Each of the nano crystallites exhibits a single crystal structure. The nano crystallites have different compositions, different crystal phases, and different lattice constants from each other. An example of the nano crystallites is represented as the formula of ZnO1-xSx with different x values in each of the nano crystallites. In addition, a hydrogen producing system is also provided.

Owner:NAT TAIWAN UNIV OF SCI & TECH

Isotropic nano crystallites of polytetrafluoroethylene (PTFE) resin and products thereof that are biaxially planar oriented and form stable

The subject invention concerns the use of staple length nano polytetrafluoroethylene (PTFE) crystallites obtained by liquid shearing PTFE dispersion particles that are wet by a liquid with a surface tension below 30 dynes / cm this liquid will spread on PTFE resin surfaces and has a contact angle of zero (0) degrees with a PTFE surface. Staple length PTFE resin micro-fibers will form rapidly under high liquid shearing force at 125° C. when diluted 1 part PTFE resin to 20 parts liquid. The subject invention also includes the application of products that are multi-directional planar oriented and isotropic as sheet, membranes and structures useful for high performance filtering, fuel and solar cells and related energy applications. It also concerns products made from formulations as coatings and product for forming, shaping and molding sheet and structures of the subject invention and methods of adhering, bond and laminating components of these structures without adhesives.

Owner:ROBERTS FLORENCE

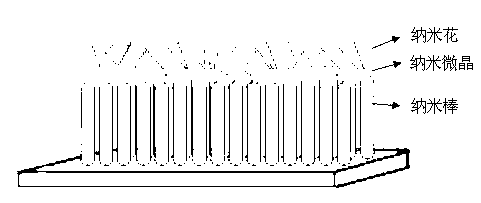

Titanium dioxide nanorod-nanocrystalline-nanoflower material and preparation method thereof

InactiveCN103311325ADirect contact guaranteeEasy to operateMaterial nanotechnologyFinal product manufactureWater bathsSlurry

The invention discloses a titanium dioxide nanorod-nanocrystalline-nanoflower material and a preparation method thereof. The structure of the material is as follows: the titanium dioxide nanorod is positioned at the bottom, the titanium dioxide nanocrystalline is positioned in the middle layer, and the titanium dioxide nanoflower is positioned on the top. The preparation process comprises the steps that titanium dioxide P25 powder and ethyecellulose are respectively prepared into ethanol solution, terpilenol and n-butyl alcohol are added to the ethanol solution, the ethyl alcohol is evaporated through water bath reaction, and titanium dioxide slurry is obtained after grinding; the titanium dioxide slurry is printed on conductive glass through the screen printing technique, and is dried under natural condition; deionized water, concentrated hydrochloric acid and butyl titanate are added to a reactor, and the conductive glass is obliquely put into reaction solution to be subjected to reaction, and the material is obtained. The titanium dioxide nanorod-nanocrystalline-nanoflower material and the preparation method thereof have the advantages that the material and the preparation method are simple and feasible, the energy consumption is low, the preparation cycle is short, the industrial batch production is easy, and the prepared material is beneficial to improving the efficiency of a dye-sensitized solar cell.

Owner:TIANJIN UNIV

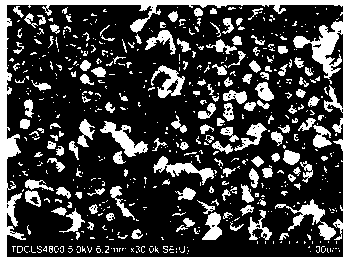

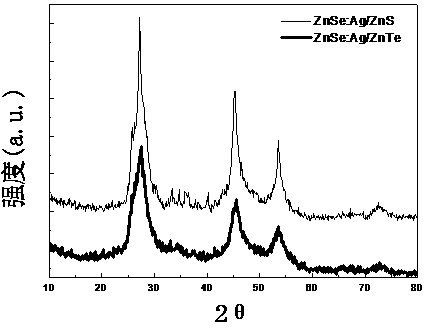

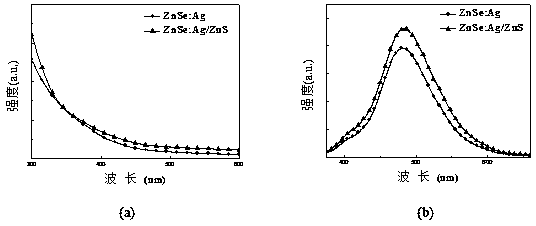

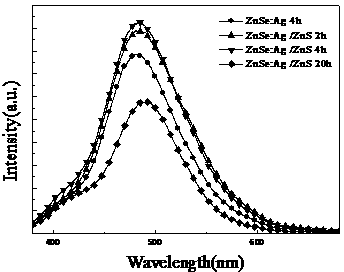

Method for surface modification of ZnSe:Ag quantum dots

InactiveCN103992797AImprove luminous performanceExperiment operation is simpleLuminescent compositionsThioureaSodium hydride

The invention relates to a method for surface modification of ZnSe:Ag quantum dots, and belongs to the technical field of composite nano microcrystalline materials. A preparation method comprises the steps: based on the preapred ZnSe:Ag quantum dots, thiourea and ZnTe are adopted for modifying the surface of the quantum dots. The modification process is carried out in a water phase, and the reaction temperature is 100 DEG C. Thiourea is used for direct surface modification to form ZnSe:Ag / ZnS quantum dots; ZnTe modification adopts a prepared Te source, that is to say, sodium borohydride (NaBH4) and a Te powder are utilized to undergo a reaction to prepare sodium hydrogen telluride (NaHTe), then NaHTe is injected into the prepared ZnSe:Ag quantum dots, and a reaction of the two components is carried out to generate a ZnSe:Ag / ZnTe quantum dot solution. The obtained product is uniform in dispersion, good in stability, and little in aggregation, and can be applied to the fields of biological fluorescent labeling, drug separation and some optoelectronic devices.

Owner:SHANGHAI UNIV

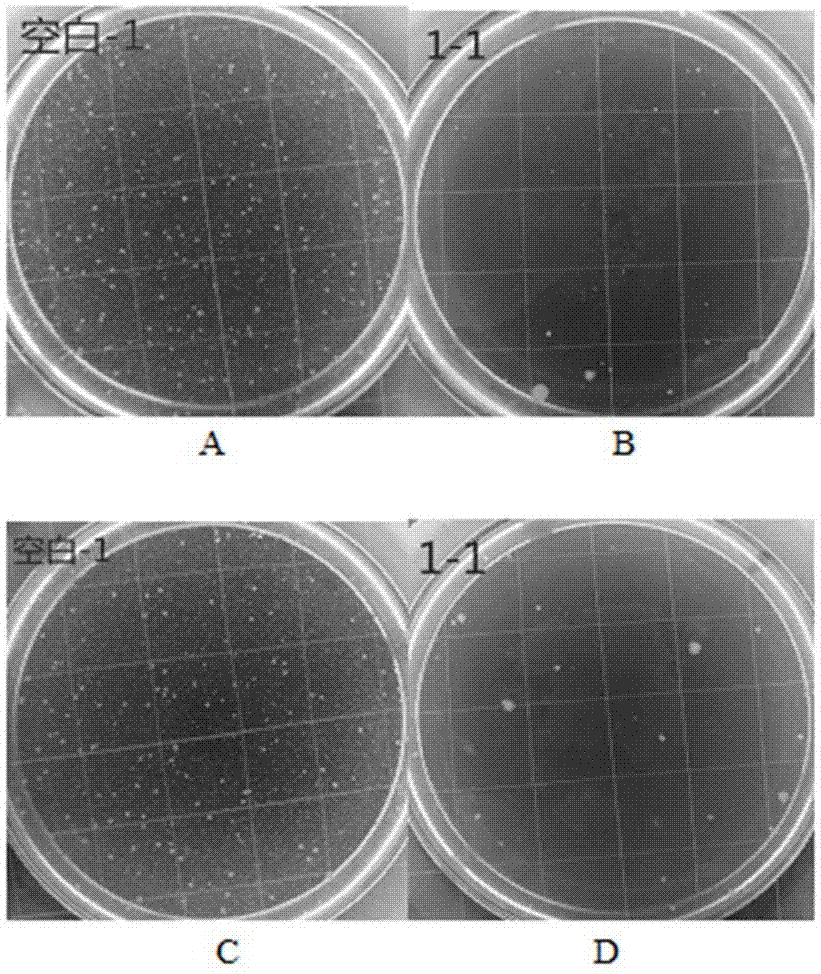

Latex without separation and with sterilizing function as well as preparation method and application thereof

ActiveCN107459685ADoes not affect film formationStrong antibacterial and deodorizing functionOrganic solventAqueous solution

The invention discloses latex without separation and with sterilizing function as well as a preparation method and application thereof. The method comprises the following steps: preparing one or more soluble metal salt into an aqueous solution, adding few rare earth mineral elements and complexing agent and then dropwise adding into an organic solvent, thereby forming a stable water-in-oil system; reacting for 30-90min under the temperature at 120-170 DEG C, cooling, centrifugally separating and filtering supernate, thereby acquiring a nano-crystalline self-dispersing component; adding the nano-crystalline self-dispersing component which is 2-10% of the latex at mass ratio into a latex solution and uniformly mixing, thereby acquiring a nanometer latex mother liquor. The nanometer latex mother liquor can be used for preparing the latex products, such as, antibacterial condoms, gloves, pillows, and the like. The latex product provided by the invention has an efficient long-lasting antibacterial odor-removing function, does not separate metal ion, is safe and environmentally friendly and is capable of effectively solving the problem of separation discoloration caused by the generally used silver ion at present.

Owner:苏州美纳福健康科技有限公司

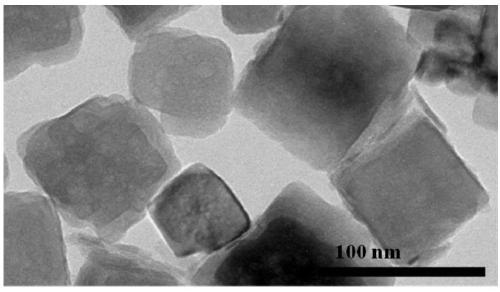

Preparation method of strontium titanate nano material with adjustable morphology

InactiveCN111470529ADiffusion limitationGood dispersionAlkaline earth titanatesNanotechnologyStrontium titanateSodium hydroxide

The invention discloses a preparation method of a strontium titanate nano material with an adjustable morphology. The method comprises the following steps: uniformly mixing a strontium nitrate solution, a sodium hydroxide solution, a butyl alcohol solution of n-butyl titanate and a butyl alcohol solution of oleic acid, and carrying out a hydrothermal reaction at 100-200 DEG C for 6-24 hours to obtain the strontium titanate nano material. Through the influence of micelles formed by self-assembly of oleic acid molecules on the dynamic behavior of directional adsorption of SrTiO3 nano micro-crystals, the morphology is finally regulated and controlled, and the prepared SrTiO3 nano material is good in dispersity, high in photocatalytic efficiency and beneficial to later application of photocatalytic devices.

Owner:NANJING UNIV OF SCI & TECH

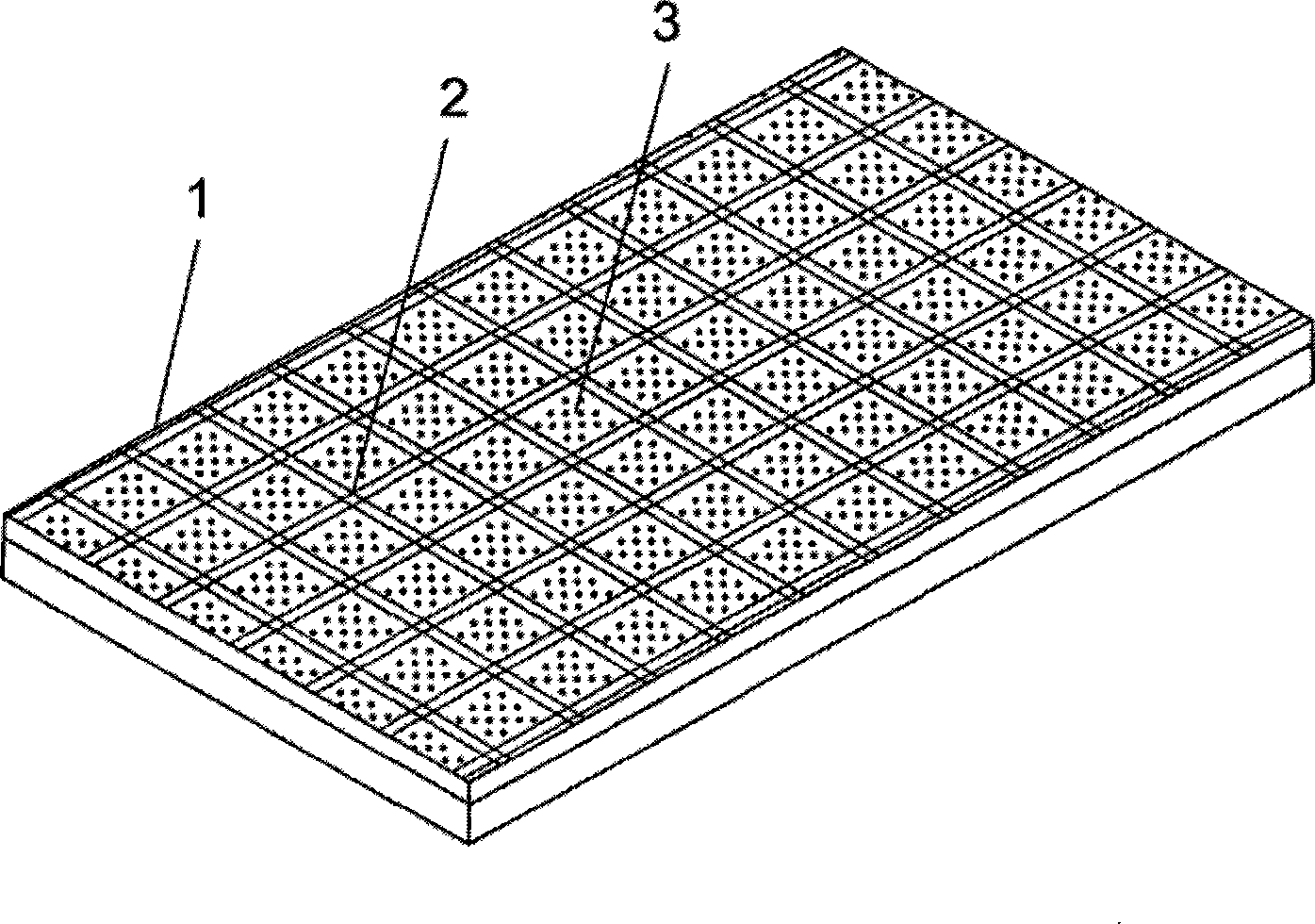

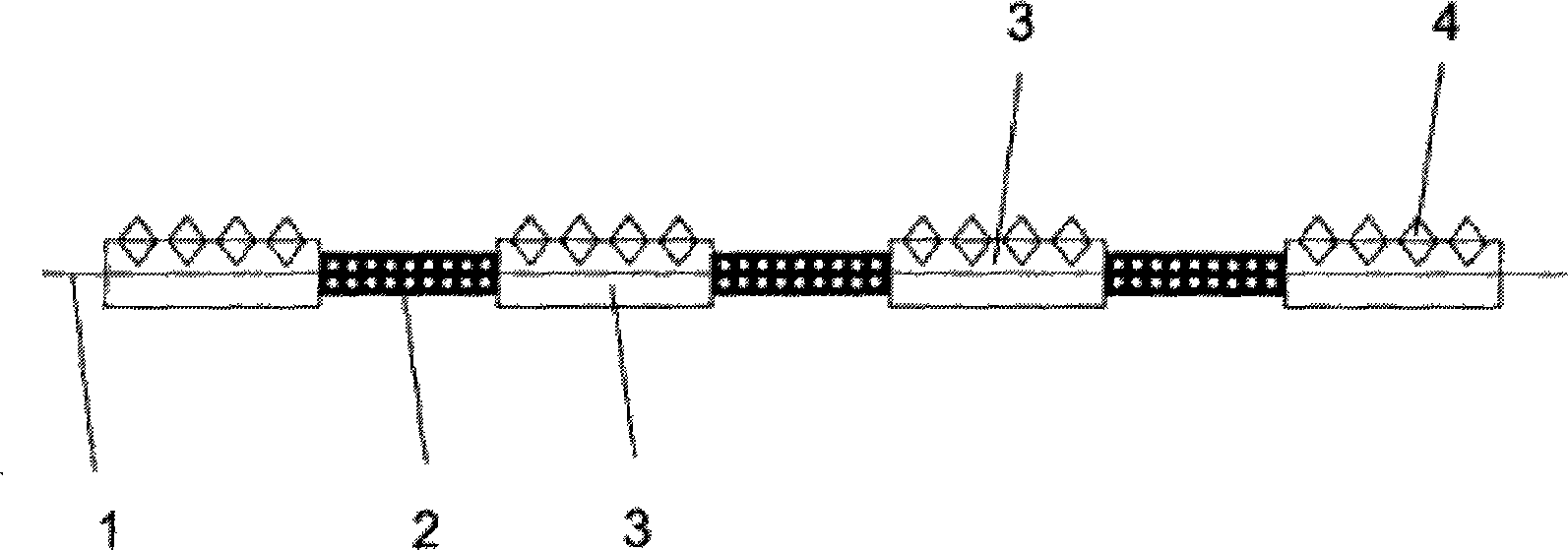

Nano micro-crystal cubic boron nitride abrasive cloth and manufacture method thereof

The invention discloses a nano microcrystalline cubic nitrification boron nitride abrasive cloth and a method for making the same. The method comprises: metal layers are distributed at intervals and coated on both sides of a substrate correspondingly, and the nano microcrystalline cubic boron nitride is embedded in the metal layers. Because the upper side and the lower side of the substrate are coated, metal base layers are formed at intervals on the substrate, and the nano microcrystalline cubic boron nitride is embedded in the metal layers simultaneously, the firmness strength of the nano microcrystalline cubic boron nitride powder embedded in the metal layers is higher. The formed nano microcrystalline cubic nitrification boron nitride abrasive cloth has the advantages of abrasion resistance, long service life, wide processing range and high polishing and grinding precision. The coated metal base layers are arranged at intervals on the nano microcrystalline cubic nitrification boron nitride abrasive cloth to make the abrasive cloth have certain flexibility, so the abrasive cloth can be used for precisely polishing and grinding products with multi-curve surfaces and complicated shapes.

Owner:FUNIK ULTRAHARD MATERIAL

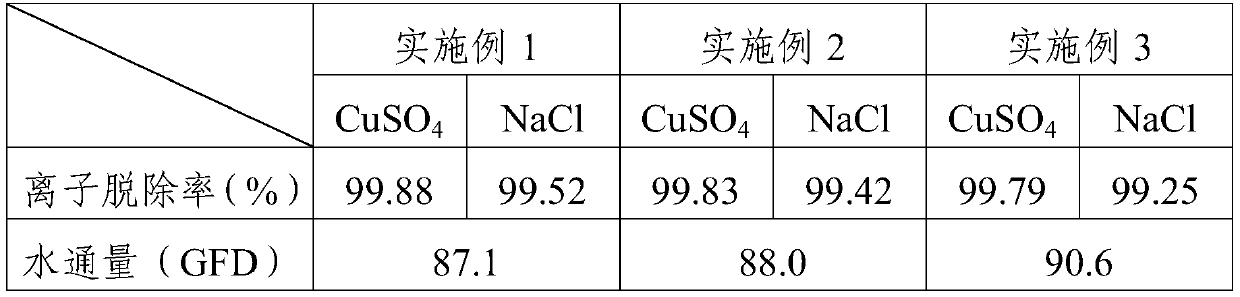

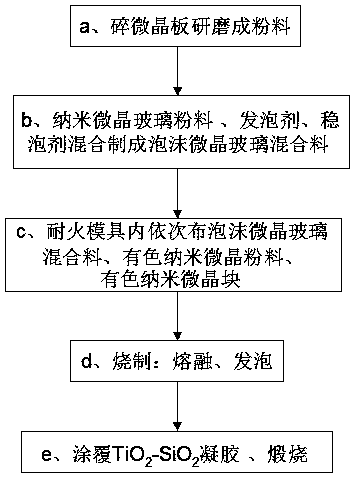

Preparation method and application of nano microcrystalline cellulose/dopamine composite film

InactiveCN111001314AEvenly dispersedHydrophilicSemi-permeable membranesGeneral water supply conservationCarrageenanMorpholine

The invention provides a preparation method and application of a nano microcrystalline cellulose / dopamine composite film, and relates to the field of semipermeable film materials, and the method comprises the following steps: preparing prefabricated cellulose; preparing nano microcrystalline cellulose;mixing the nano microcrystalline cellulose, dopamine, K-carrageenan and N-methyl morpholine oxide, heating to 110-120 DEG C, stirring for 30 to 40min, dissolving and clearing, adding a trihydroxymethylaminomethane buffer solution to adjust the pH value to 8-9, standing for 20 to 25h, decompressing and defoamingtoobtain a film solution, casting the filmsolution onto a polytetrafluoroethylene glass plate, putting the mixture into a drying oven to be subjected to vacuum drying for 10 to 15h at 30 to 50 DEG C, immersing the polytetrafluoroethylene glass plate into deionized water, scraping afilm off by a scraper, and drying to obtainthe nano microcrystalline cellulose / dopamine composite film.The nano microcrystalline cellulose / dopamine composite film has the advantages of good ion removal rate (up to 99% or above), extremely high water flux, extremely high application prospect in sewagetreatment and sea water desalination, and good mechanical property and swelling property.

Owner:安徽勉以信网络科技有限公司

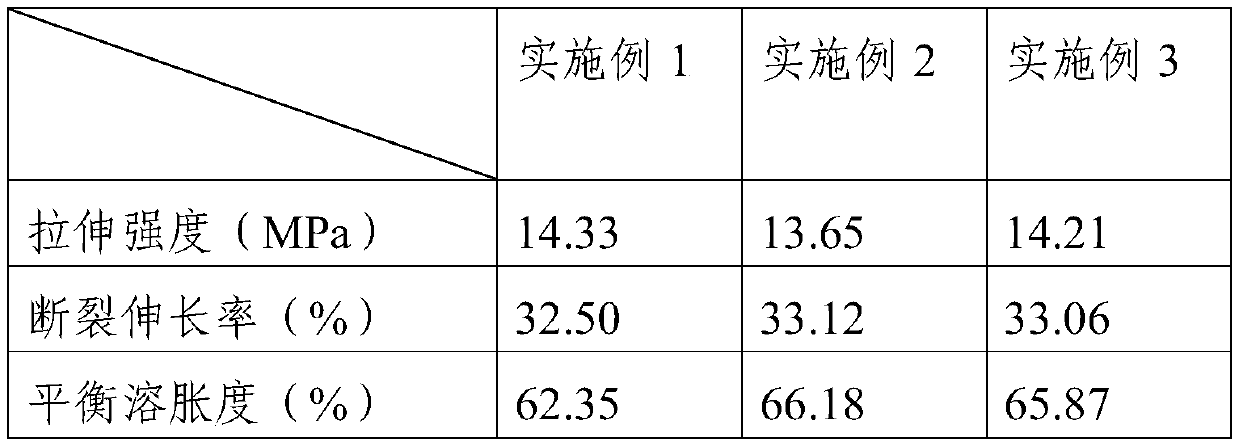

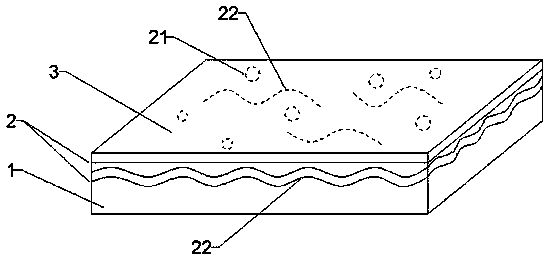

Nanocrystalline plate

PendingCN107892484AImprove insulation effectLight weightGlass shaping apparatusFoaming agentAnti bacteria

The invention provides a nanocrystalline plate, which comprises a foam nanocrystalline glass layer, a colored nanocrystalline glass layer and a TiO2-SiO2 antibacterial coating from bottom to top, wherein the colored nanocrystalline glass layer is formed by melting upper-layer colored nanocrystalline blocks and lower-layer colored nanocrystalline powder and has texture within the layer. A preparation method for the nanocrystalline plate comprises the following steps: a. grinding broken nanocrystalline plates into powder; b. mixing nanocrystalline glass powder, a foaming agent and a foam stabilizer to prepare a foam glass ceramic mixture; c. successively putting the foam glass ceramic mixture, the colored nanocrystalline powder and the colored nanocrystalline blocks into a refractory mold; d, carrying out firing, melting and foaming; and e, successively carrying out coating with TiO2-SiO2 gel and calcining. The nanocrystalline plate of the invention has good heat-insulating property, small specific gravity, high mechanical strength, beautiful appearance and good anti-bacterial effect; the water resistance of the nanocrystalline plate is improved by 50 to 60% compared with ordinary microcrystalline plates; and the nanocrystalline plate can be widely applied to interior decoration.

Owner:江西高透基板材料科技有限公司

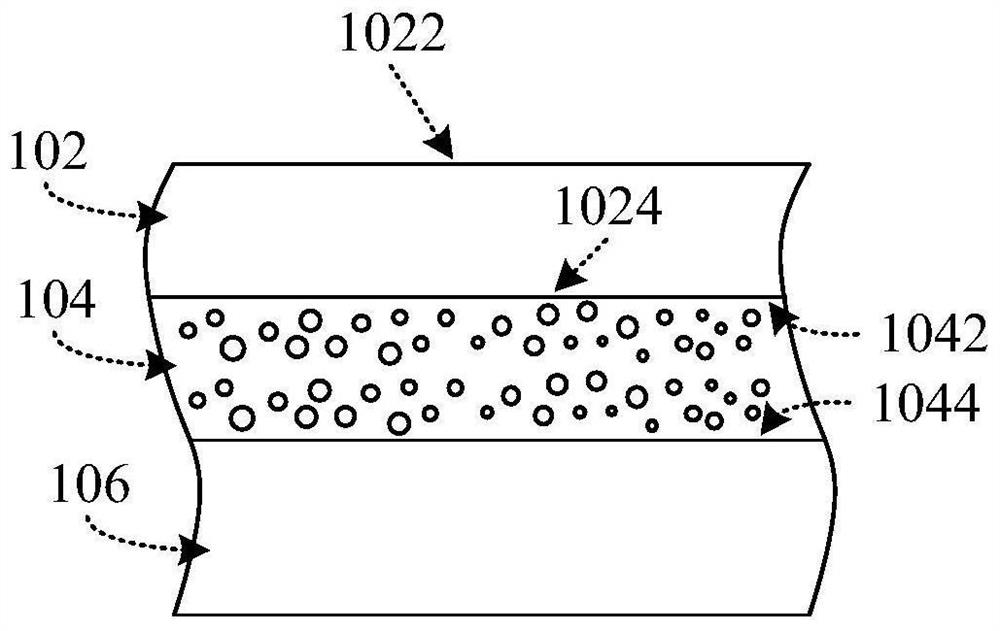

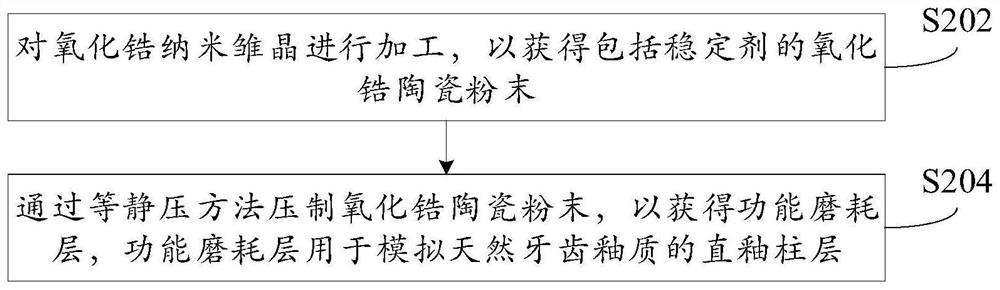

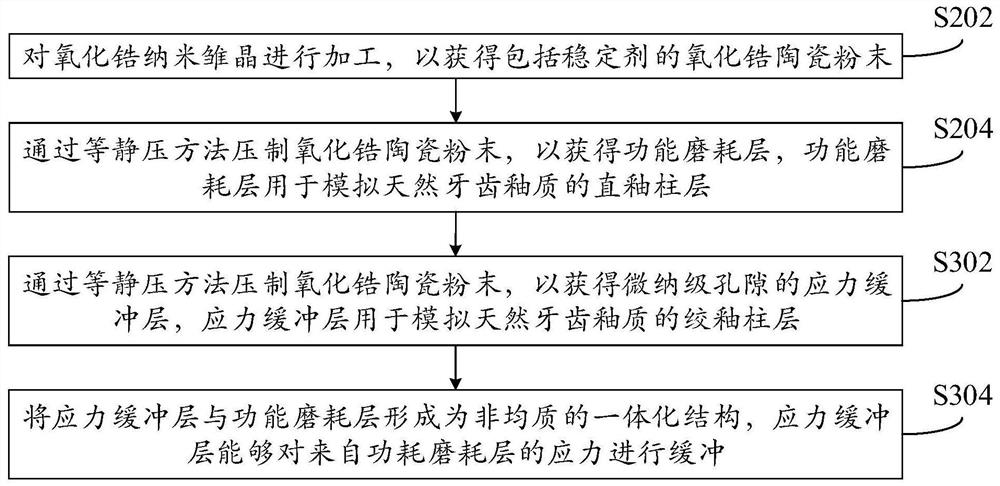

Bionic enamel zirconia ceramic material block, dental prosthesis and preparation method

PendingCN112754943AReduce wearExtended service lifeImpression capsDentistry preparationsNatural toothTooth enamel

The invention relates to a bionic enamel zirconia ceramic material block, a dental prosthesis and a preparation method. The bionic enamel zirconia ceramic material block comprises a functional wearing layer; the functional wearing layer comprises zirconia and a stabilizer used for stabilizing the zirconia; the zirconia is formed by zirconia nano crystallites; intragranular defects are formed in the nano crystallites; the outer surface of the functional wearing layer is used for forming an occlusal surface; and the functional wearing layer is used for simulating the straight enamel rod layer of natural tooth enamel. According to the technical scheme disclosed by the invention, the situation that the dental prosthesis excessively abrades jaw teeth can be relieved; the obtained zirconia ceramic material block has the advantages of high strength, low hardness and low elastic modulus; the probability of breaking of the bionic enamel zirconia ceramic material block and the dental prosthesis is reduced; the service lives of the tooth prosthesis and the jaw teeth are prolonged; in addition, the appearance of the bionic enamel zirconia ceramic material block and the appearance of the dental prosthesis are very similar to the appearance of natural teeth; and the bionic enamel zirconia ceramic material block and the dental prosthesis have excellent light transmission, transparency and polishing degree.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

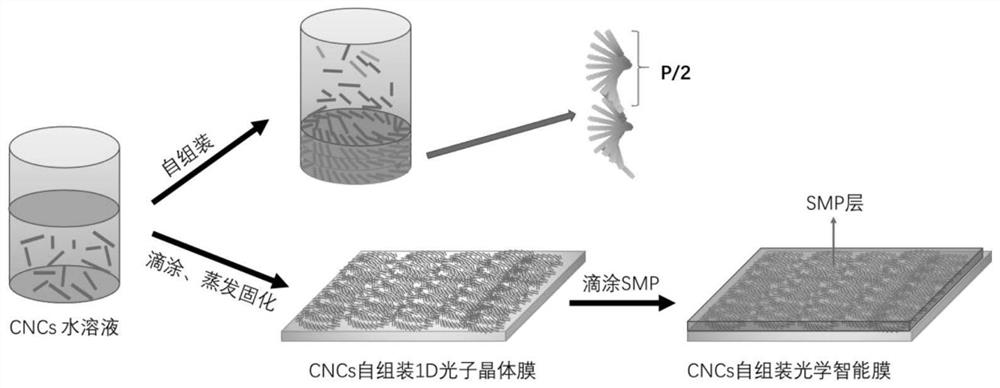

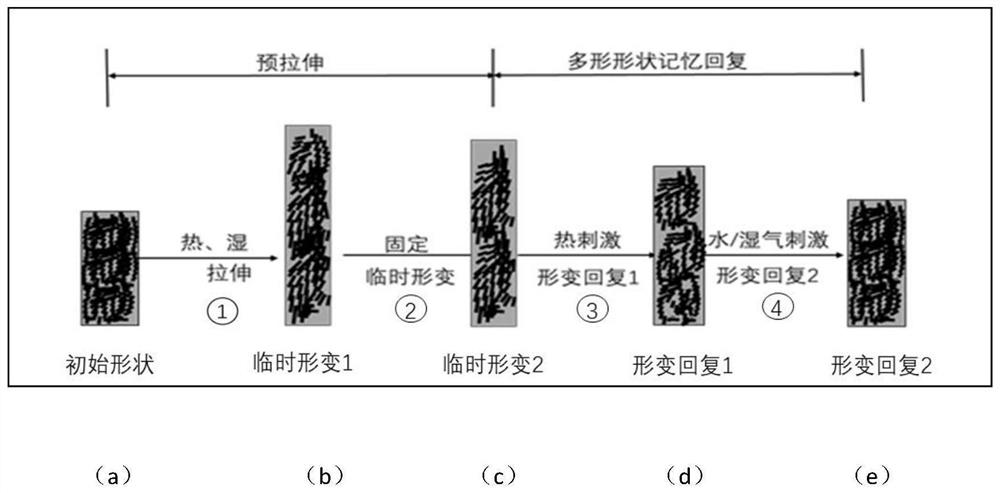

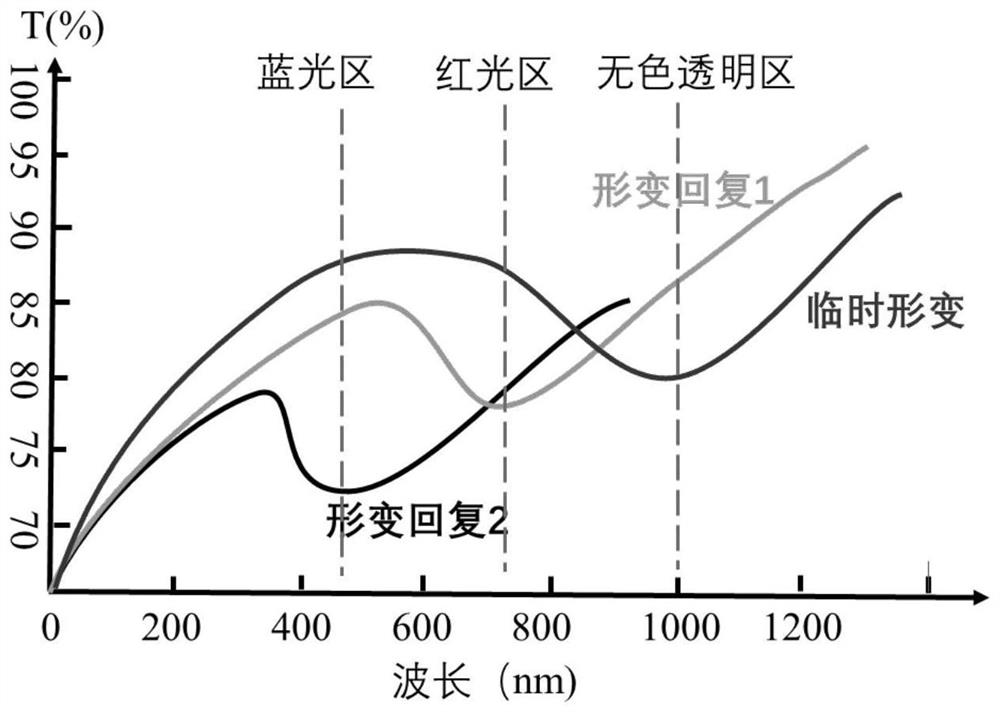

Multi-shape- shape- memory driven intelligent optical film with multi-structural color conversion, and preparation method and application of multi-shape shape memory driven intelligent optical film with multi-structural color conversion

ActiveCN113061274APossesses polymorphic shape memory propertiesAdjustable multiple structural color transition propertiesPolyurea/polyurethane coatingsPolyether coatingsGlass chipThermal stability

The invention belongs to the technical field of optical intelligent materials, and discloses a multi-shape-memory-driven intelligent optical film with multi-structural color conversion and a preparation method and application thereof. The intelligent optical film is prepared by the following steps: dissolving cellulose nanocrystal powder in deionized water, carrying out ultrasonic treatment at room temperature, and adjusting the pH value to 5-7 to prepare a CNCs suspension; dispensing the CNCs suspension onto a glass substrate, and drying at room temperature to obtain a self-assembled cellulose nanocrystalline film; and uniformly dispensing and transferring an amorphous polymer organic solution to the surface of the self-assembled cellulose nanocrystalline film, and curing at 40-80 DEG C in vacuum to obtain the self-assembled cellulose nanocrystalline film. The intelligent optical film provided by the invention has a multi-shape memory performance under multiple stimulations of heat, water and moisture, and also has an adjustable multi-structure color conversion performance. The chiral nematic structure of the cellulose nanocrystallines is maintained, and the thermal stability, the mechanical strength, the flexibility and the like are remarkably improved.

Owner:GUANGDONG UNIV OF TECH

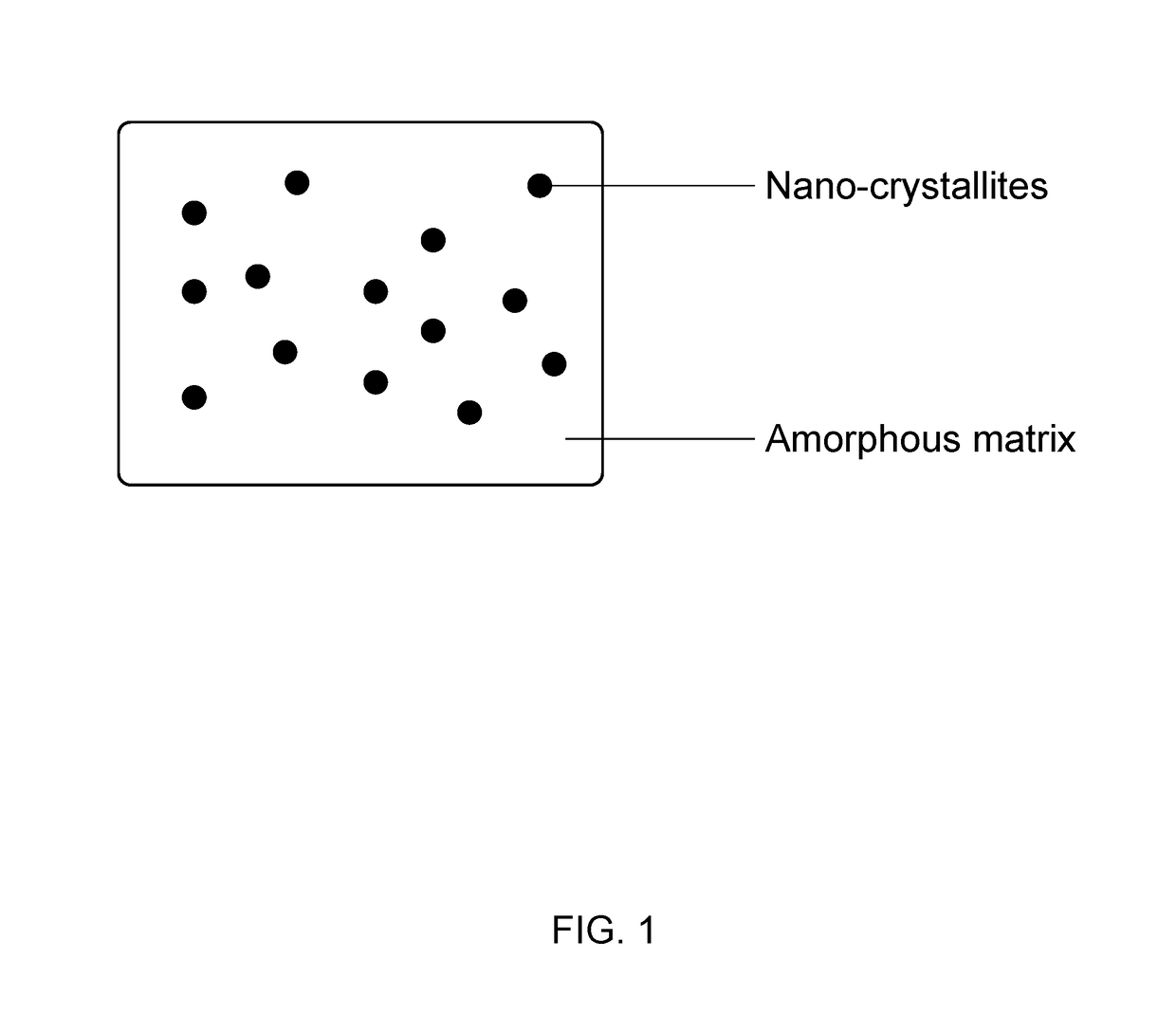

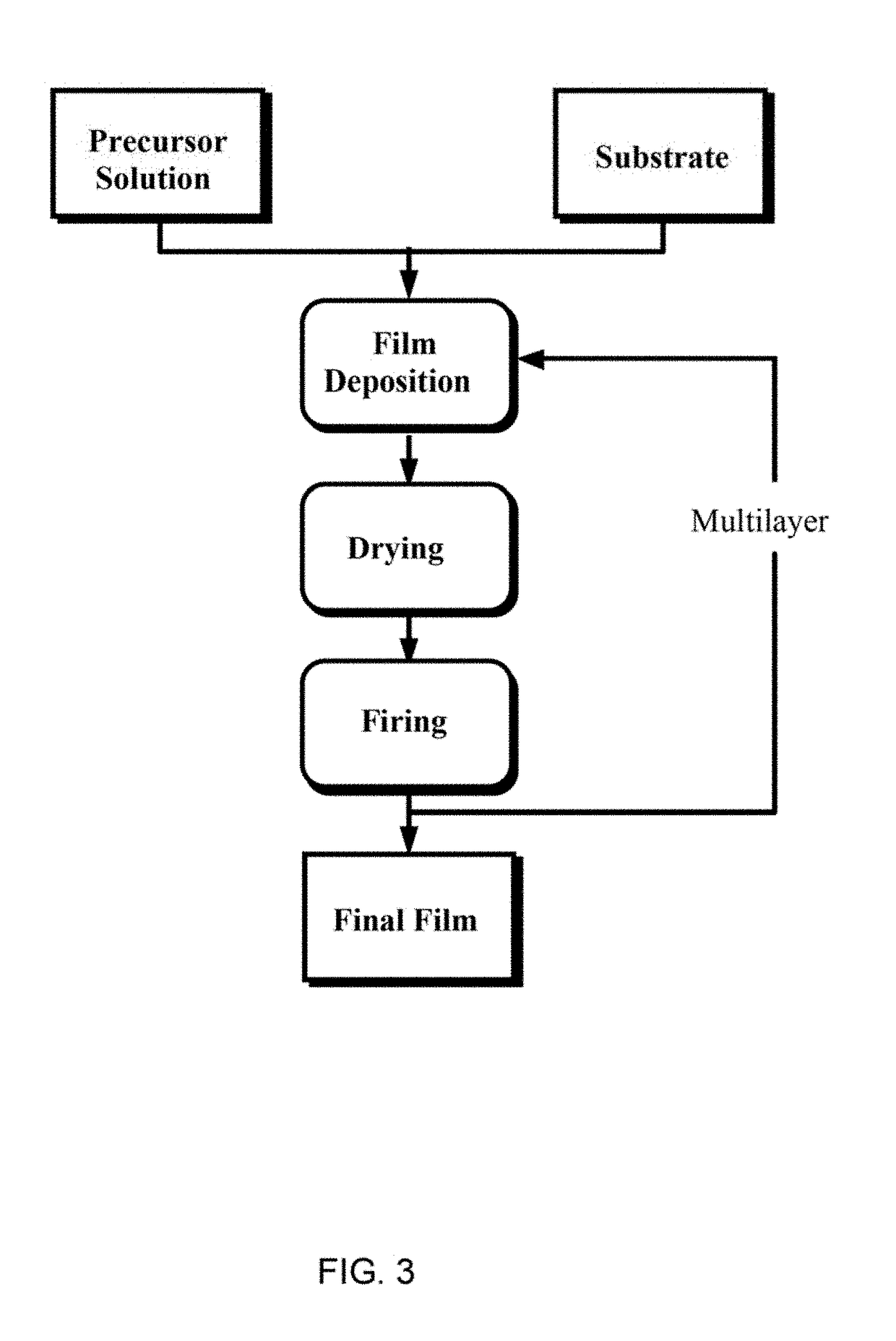

Nano-composite structure and processes making of

A nano-composite structure comprises of an amorphous matrix with embedded nano-crystallites. The nano-crystallites are precipitated from the amorphous matrix via heat treatment of a solution mixture of metal salts or metalorganic compounds to an appropriate temperature range and with a suitable duration, or heating of a mixture of non-crystalline compounds. The nano-crystallites are self-assembled in the amorphous matrix without forming agglomerates or distinguished grain boundaries. The nano-composite structure can be used for transparent display, transparent optical ceramics, protection armor, nuclear protection, pulsed power, high voltage electronics, high energy storage system and high power microwave systems.

Owner:GUO XIAOMEI +3

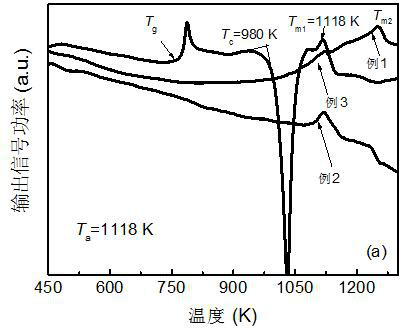

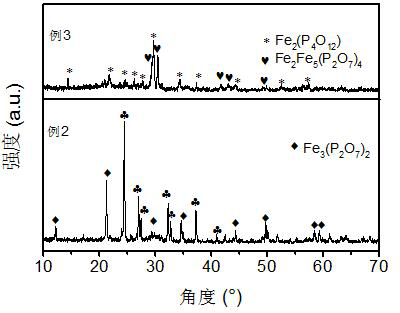

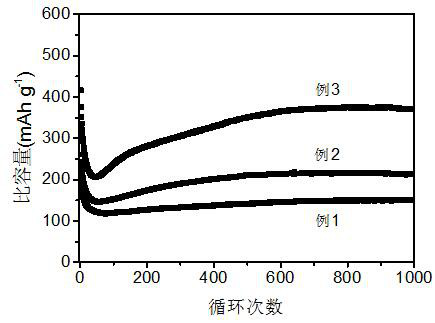

High-performance variable-valence metal ion oxide-containing microcrystalline glass electrode material as well as preparation method and application thereof

PendingCN114420932AShorten the transmission distanceInhibition of volume expansionSecondary cellsNegative electrodesPollutionMaterials science

The invention relates to a high-performance variable-valence metal ion oxide-containing microcrystalline glass electrode material and a preparation method and application thereof, and belongs to the field of energy storage and material preparation. The preparation method of the microcrystalline glass electrode material comprises the following steps: performing high-temperature heat treatment on oxide glass containing variable valence metal ions in an air or reducing atmosphere within a range higher than a crystallization initial temperature for 0.5-24 hours to prepare the high-performance nano microcrystalline glass electrode material containing variable valence metal ions. According to the invention, the content of low-valence metal ions in the glass is improved, so that the conductivity of an electrode is improved, the precipitation of crystals is promoted, and the energy storage site is improved; and the reversible capacity and the cycling stability of the glass electrode material containing variable valence metal ions are greatly improved. In addition, the preparation method is simple in production process and free of environmental pollution, and has an excellent development prospect.

Owner:QILU UNIV OF TECH

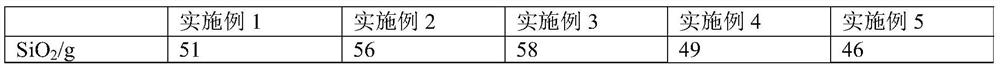

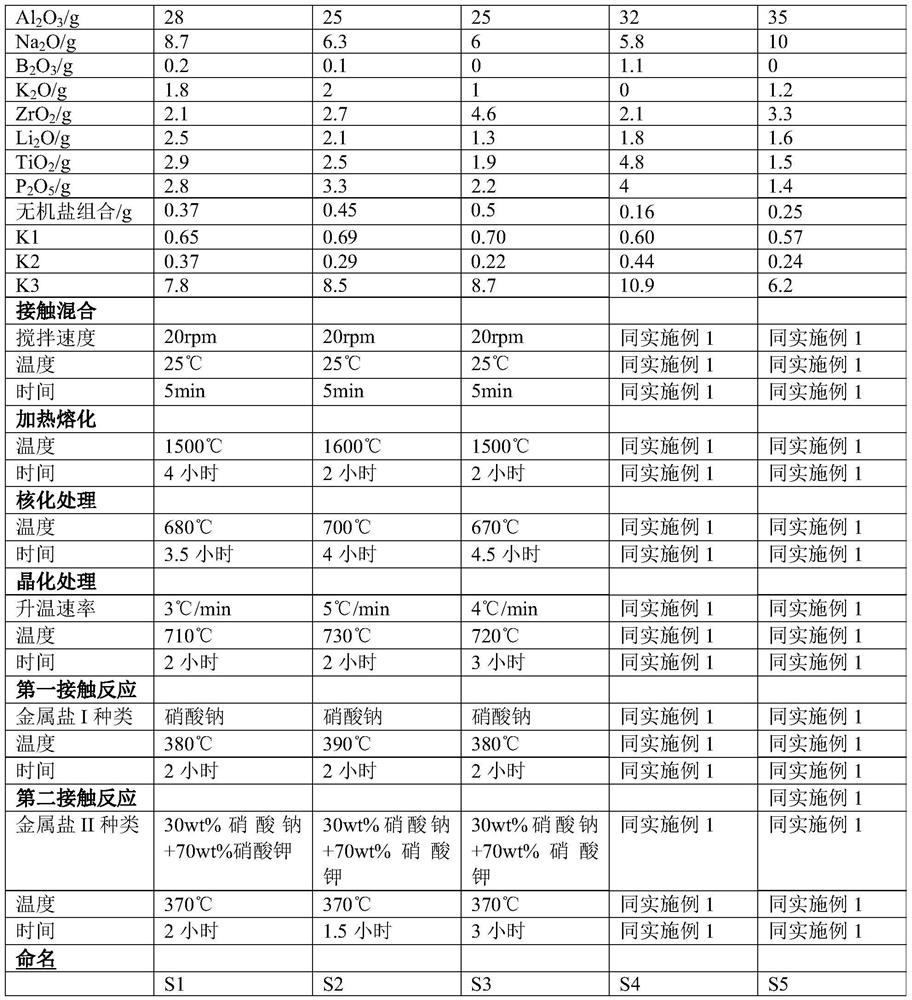

Composition for glass, nano microcrystalline glass and preparation method and application thereof

PendingCN113698095AHigh light transmittanceImprove drop resistanceGlass tempering apparatusTelephone set constructionsPhysical chemistryOptical transmittance

The invention relates to the technical field of microcrystalline glass, and discloses a composition for glass, nano microcrystalline glass and a preparation method and application thereof. On the basis of the total mass of the composition for the glass, the composition for the glass contains 48 to 60 mass percent of SiO2, 25 to 35 mass percent of Al2O3, 5 to 10 mass percent of Na2O, 0 to 2 mass percent of K2O, 0 to 2 mass percent of B2O3, 2 to 6 mass percent of ZrO2, 1 to 3 mass percent of Li2O, 1.5 to 5 mass percent of TiO2 and 1 to 4 mass percent of P2O5. The nano microcrystalline glass formed by adopting the composition for glass provided by the invention not only has good light transmittance, but also has good mechanical properties such as drop resistance, compression resistance, aging resistance and the like.

Owner:河南旭阳光电科技有限公司 +1

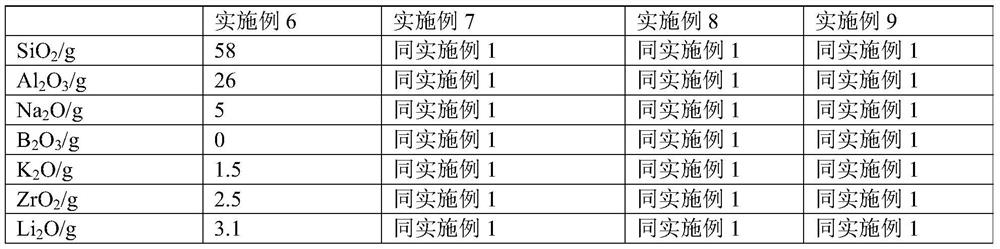

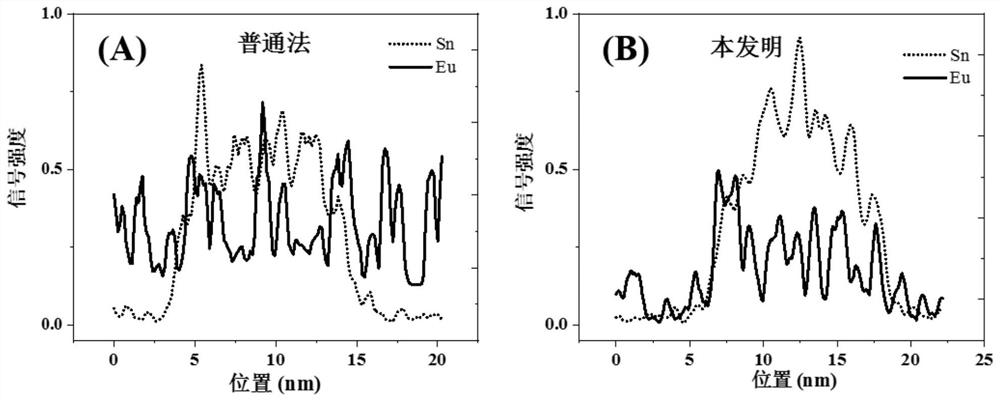

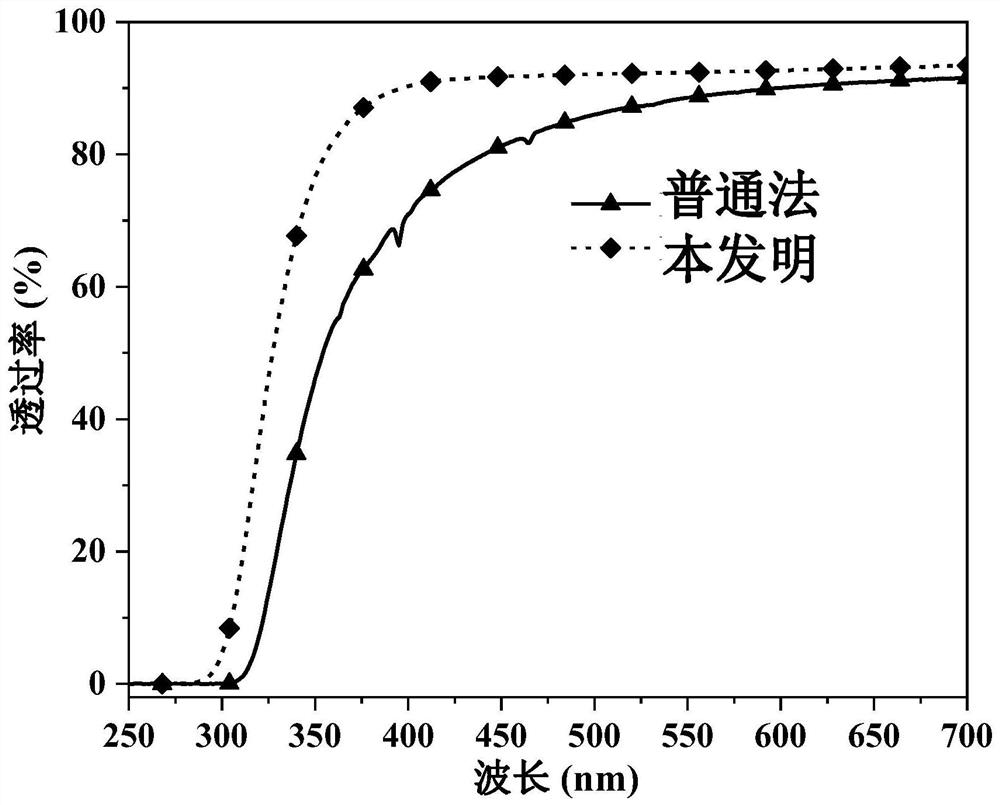

Nano microcrystalline glass containing stannic oxide and preparation method of nano microcrystalline glass

The invention provides nano microcrystalline glass containing stannic oxide and a preparation method of the nano microcrystalline glass, and belongs to the technical field of inorganic luminescent materials. The preparation method of the nano microcrystalline glass containing stannic oxide comprises the following steps: porous glass solution doping; primary heat treatment; acid treatment; and secondary heat treatment. The inventor of the invention accidentally discovers that a fact that light-emitting ions outside stannic oxide crystals are removed, only ions in stannic oxide emit light, but the whole stannic oxide emits stronger light, that is, porous glass is sequentially doped with a mixed solution containing tin ions and light-emitting ions, subjected to primary heat treatment and thensubjected to acid treatment, so that the transparency of the glass can be effectively improved, and the light-emitting performance of the high-silica glass is improved. The method breaks through theinertial understanding that personnel in the industry pursue uniform distribution of active ions to improve the overall light-emitting effect of the glass.

Owner:JINAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com