Bionic enamel zirconia ceramic material block, dental prosthesis and preparation method

A technology of zirconia ceramics and bionic teeth, applied in dental preparations, dental prostheses, dentistry, etc., can solve problems such as excessive wear of jaws and teeth, achieve the effects of reducing stress, improving user experience, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

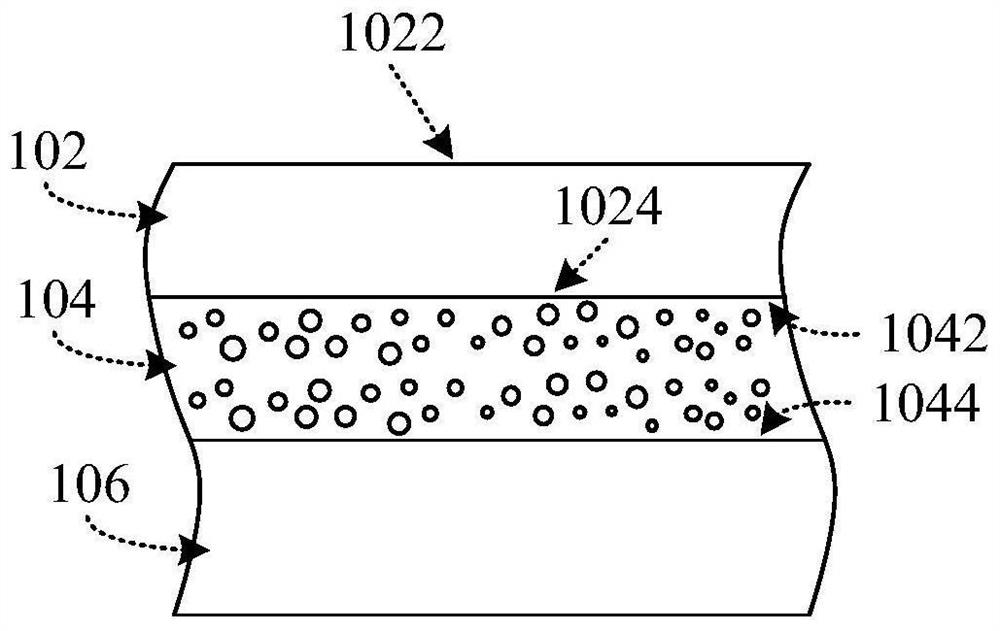

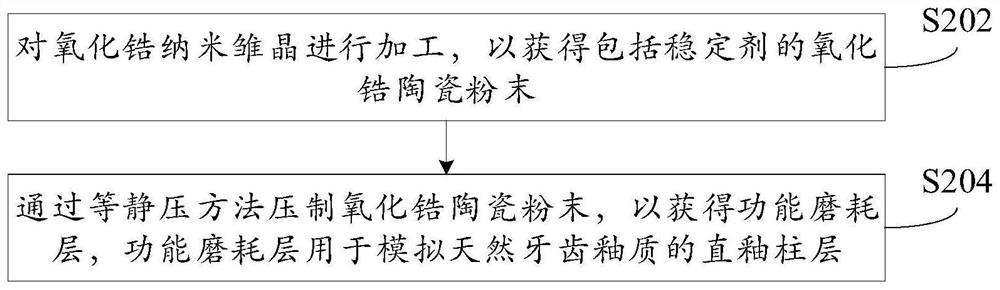

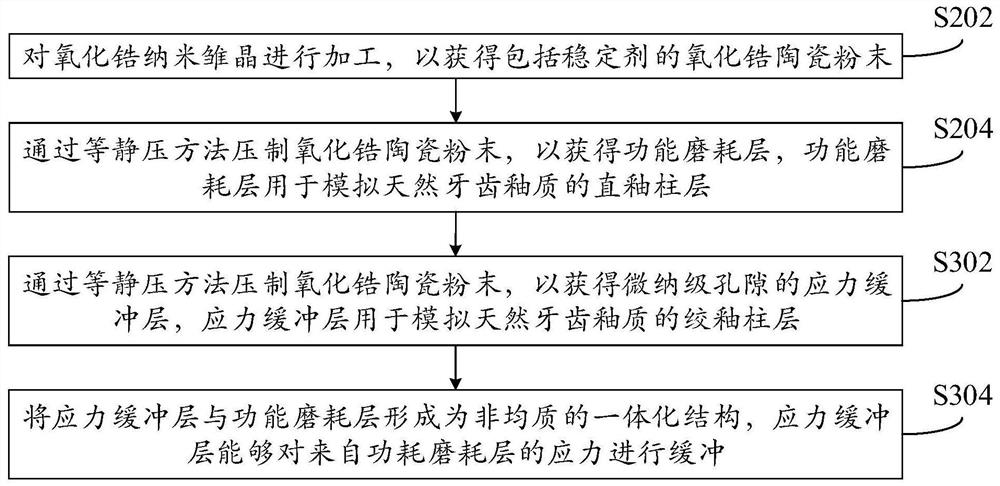

[0099] Such as figure 2 As shown, the preparation method of the bionic enamel zirconia ceramic material block according to the embodiment of the present disclosure includes:

[0100] Step S202, processing the zirconia nanocrystals to obtain zirconia ceramic powder including a stabilizer.

[0101] In the above examples, the processing of zirconia nanocrystals includes three steps of hydrothermal reaction, hydrolysis reaction and powder acquisition:

[0102] (1) Hydrothermal reaction

[0103] Prepare a mixed aqueous solution of zirconium oxychloride and carbonamide with a certain volume and concentration to form [Zr 4+ ]=0.4mol / L, [CO(NH 2 ) 2 ]=1mol / L reaction liquid. The reaction feed liquid is placed in a polytetrafluoroethylene-lined hydrothermal synthesis reactor, and reacted at a temperature of 150°C±10°C for 3 hours to form a gel.

[0104] (2) Hydrolysis reaction

[0105] Take out the gel obtained after the hydrothermal reaction, add a certain amount of the origin...

Embodiment 1

[0147] A method for preparing a bionic enamel zirconia ceramic material block of the present disclosure has the following steps:

[0148] (1) Design a zirconia material block composed of a three-layer material of a functional wear layer, a stress buffer layer and a flexural base layer.

[0149] (2) The zirconia ceramic powders used for the functional wear layer, the stress buffer layer and the anti-bending base layer are prepared respectively by hydrothermal method; wherein, the functional wear layer is 10mol% cerium oxide, and the anti-bending base layer is 3mol% cerium oxide Yttrium, the stress buffer layer is 10 mol% cerium oxide and 3 mol% yttrium oxide.

[0150] (3) layered pressing material block / disc by isostatic pressing method, wherein the thickness of the functional wear layer is 0.3mm, the thickness of the stress buffer layer is 0.1mm, and the thickness of the anti-bending base layer is 0.5mm; the material block / The three-layer structure of the disc is from top to...

Embodiment 2

[0152] A method for preparing a bionic enamel zirconia ceramic material block of the present disclosure has the following steps:

[0153] (1) Design a zirconia material block composed of a three-layer material of a functional wear layer, a stress buffer layer and a flexural base layer.

[0154] (2) The zirconia ceramic powders for the three layers of functional wear layer, stress buffer layer and anti-fracture base layer were prepared respectively by hydrothermal method. Wherein, the functional wear layer is 8 mol% magnesia, the anti-bending base layer is 5 mol% yttrium oxide, and the stress buffer layer is 12 mol% cerium oxide and 10 mol% magnesia.

[0155] (3) The material block / disk is laminated and pressed by isostatic pressing, wherein the thickness of the functional wear layer is 0.4 mm, the thickness of the stress buffer layer is 0.18 mm, and the thickness of the anti-folding base layer is 1.2 mm. The three-layer structure of the material block / disk is respectively fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com