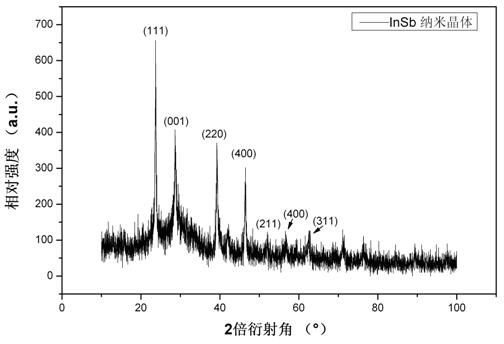

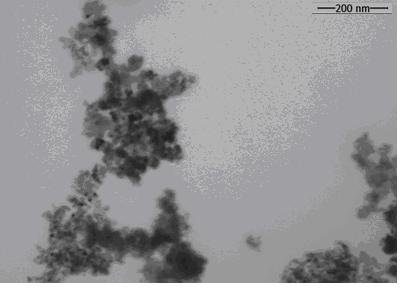

Preparation method of indium antimonide nanocrystal

A technology of nanocrystals and indium antimonide, which is applied in the field of preparation of III-V nanocrystal materials, can solve problems such as high reaction temperature, highly toxic antimony source or harsh treatment conditions, uncontrollable material structure and morphology process, and achieve The effect of uniform particles, stable properties and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

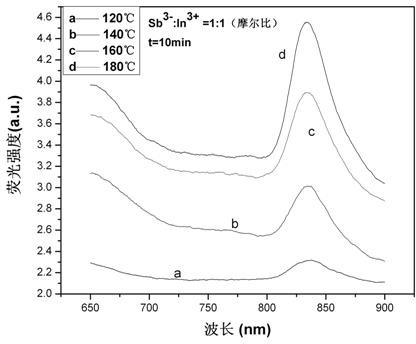

Embodiment 1

[0017] a. Add 110mg Sb 2 o 3 , 290mg In(NO 3 ) 3 9 / 2 H 2 0. 50mg PEG200 and 25mL ethylene glycol were mixed in a 250mL three-necked flask as a growth solution;

[0018] b. Add 200mg NaBH 4 Dissolved in 5mL ethylenediamine as a stock solution;

[0019] c. Put the growth solution in an oil bath to 140°C under nitrogen protection atmosphere, and keep magnetic stirring for 30 minutes. Then adjust the oil temperature to the reaction temperature of 120°C; quickly inject the stock solution into the growth solution with a syringe (~2S), keep the oil bath temperature and magnetic stirring;

[0020] d. Sampling the reaction solution from the reaction to 10 minutes, adding an appropriate amount of ethanol to the extracted reaction solution, and centrifuging at 15000 rpm for 20 minutes to separate the product antimonide (InSb).

Embodiment 2

[0022] a. Add 110mg Sb 2 o 3 , 290mg In(NO 3 ) 3 9 / 2 H 2 0. 50mg PEG200 and 25mL ethylene glycol were mixed in a 250mL three-necked flask as a growth solution;

[0023] b. Add 200mg NaBH 4 Dissolved in 5mL ethylenediamine as a stock solution;

[0024] c. Under a nitrogen protective atmosphere, bring the oil bath of the growth solution to 140°C and keep it under magnetic stirring for 30 minutes; then adjust the temperature of the oil margin to the reaction temperature of 140°C. Use a syringe to quickly inject the stock solution into the growth solution (~2S), keep the oil bath temperature and magnetic stirring;

[0025] d. Sampling the reaction solution from the reaction to 10 minutes; add an appropriate amount of ethanol to the extracted reaction solution, and centrifuge at 15000 rpm for 20 minutes to separate the product indium antimonide (InSb).

Embodiment 3

[0027] a. Add 110mg Sb 2 o 3 , 290mg In(NO 3 ) 3 9 / 2 H 2 0. 50mg PEG200 and 25mL ethylene glycol were mixed in a 250mL three-necked flask as a growth solution;

[0028] b. Add 200mg NaBH 4 Dissolved in 5mL ethylenediamine as a stock solution;

[0029] c. Under a nitrogen protective atmosphere, bring the oil bath of the growth solution to 140°C and keep magnetic stirring for 30 minutes; then adjust the temperature of the oil margin to the reaction temperature of 160°C. Use a syringe to quickly inject the stock solution into the growth solution (~2S), keep the oil bath temperature and magnetic stirring;

[0030] d. Sampling the reaction solution from the reaction to 10 minutes; add an appropriate amount of ethanol to the extracted reaction solution, and centrifuge at 15000 rpm for 20 minutes to separate the product indium antimonide (InSb).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com