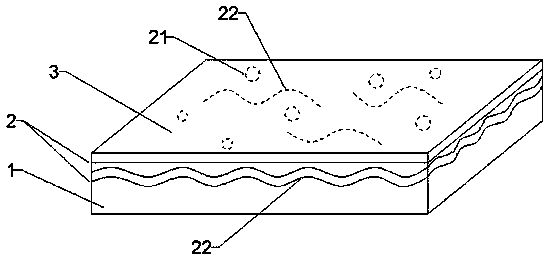

Nanocrystalline plate

A technology of nanocrystalline and foamed glass-ceramics, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of poor physical and chemical stability, difficult construction, cracking, etc. Natural and smooth, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

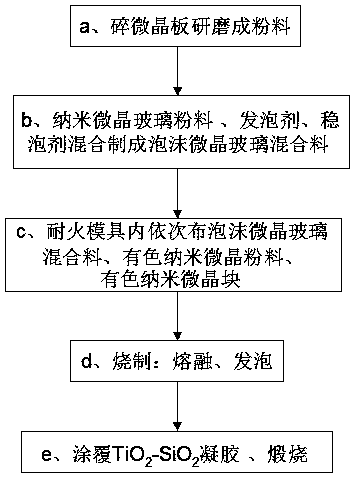

[0040] The nano crystal plate of the present embodiment is made by the following steps:

[0041] a. Add the crushed nano crystallite plate produced in the production process into a ball mill, and grind it into powder with a particle size of 170 mesh. The mass percentage composition of the crushed microcrystal plate includes: SiO 2 72.0%, Al 2 o 3 0.388%, Fe 2 o 3 0.012%, CaO 12.5%, MgO 1.6%, Na 2 O 13.1%, Sb 2 o 3 0.4%;

[0042] b. In weight percentage, get 90% of the nano glass-ceramic powder, 8% of foaming agent, and 2% of foam stabilizer, mix and make a particle size of 170 mesh foamed glass-ceramics mixture, the foaming agent NaSiO 3 , CeO 2 Composite blowing agent composed of;

[0043] c. Spread and scrape the foamed glass-ceramic mixture in the refractory mold with a distributing machine; The colored nano crystallite powder of 1000 °C, the particle size is 5 ~ 18 mesh, and the color nano crystallite block with an initial melting temperature of 1000 °C is s...

Embodiment 2

[0048] The nano crystal plate of the present embodiment is made by the following steps:

[0049] a. Add the crushed nano crystallite plate produced in the production process into a ball mill, and grind it into powder with a particle size of 240 mesh. The mass percentage composition of the crushed microcrystal plate includes: SiO 2 73.0%, Al 2 o 3 0.3%, Fe 2 o 3 0.1%, CaO 10.4%, MgO1.8%, K 2 O 14.1%, Sb 2 o 3 0.3%;

[0050] B, in weight percent, get described nano glass-ceramics powder 95%, blowing agent 4.5%, foam stabilizer 0.5%, mix and make particle size be that the foamed glass-ceramics mixture of 240 objects, described blowing agent for Al 3 C 4 , composite blowing agent composed of SiC;

[0051] c. Spread and scrape the foamed glass-ceramic mixture in the refractory mold with a distributing machine; The colored nano-crystallite powder of 5°C, the particle size is 5~18 mesh, and the color nano-crystallite block with an initial melting temperature of 1100°C ...

Embodiment 3

[0056] The nano crystal plate of the present embodiment is made by the following steps:

[0057] a. Add the crushed nano crystallite plate produced in the production process into a ball mill, and grind it into powder with a particle size of 200 mesh. The mass percentage composition of the crushed microcrystal plate includes: SiO 2 72.2%, Al 2 o 3 0.358%, Fe 2 o 3 0.088%, CaO 11.5%, MgO 1.7%, R 2 O 13.8%, Sb 2 o 3 0.354%;

[0058] b. In weight percentage, get 92.5% of the nano glass-ceramic powder, 6% of foaming agent, and 1.5% of foam stabilizer, mix and make a particle size of 200 mesh foamed glass-ceramic mixture, the foaming agent for Al 3 C 4 、NaNO 3 Composite blowing agent composed of;

[0059] c. Spread and scrape the foamed glass-ceramic mixture in the refractory mold with a distributing machine; The colored nano crystallite powder of 5°C, the particle size is 5 ~ 18 mesh, and the color nano crystallite block with an initial melting temperature of 1020°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com