Cordierite-based nanometer glass-ceramic and preparation method thereof

A technology of nano-crystallite and cordierite, which is applied in the field of cordierite-based nano-glass-ceramics and its preparation, can solve the problems of lack of mechanical properties of cordierite-based glass-ceramics, and achieve high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

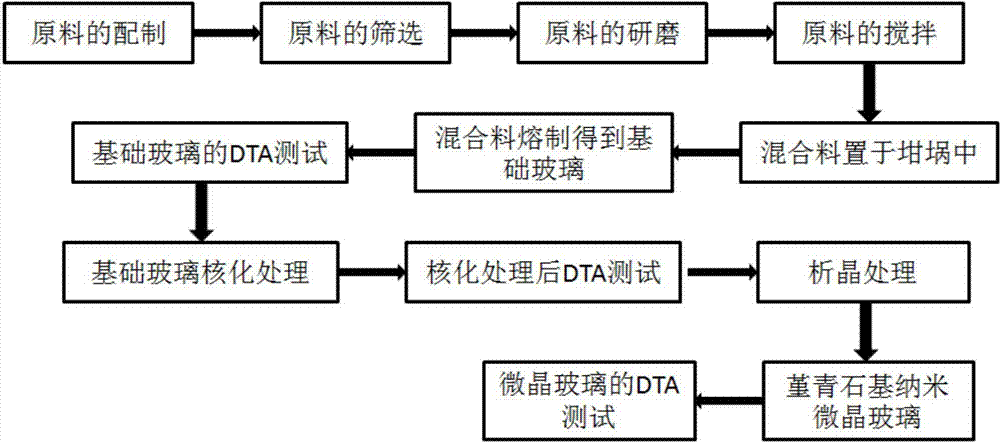

[0065] The invention provides a preparation method of cordierite-based nano glass ceramics, comprising the following steps:

[0066] Main component raw materials including silicon source, magnesium source and aluminum source, crystal nucleating agent raw materials including titanium source, zirconium source and phosphorus source, adjustment material raw materials including calcium source, sodium source and potassium source, and auxiliary materials including boron source The flux raw material is melted to obtain the basic glass;

[0067] The base glass is subjected to nucleation treatment and crystallization treatment to obtain cordierite-based nano glass ceramics.

[0068] The present invention will include main component raw materials of silicon source, magnesium source and aluminum source, crystal nucleating agent raw materials including titanium source, zirconium source and phosphorus source, regulator raw materials including calcium source, sodium source and potassium sour...

Embodiment 1

[0083] 24wt% MgO, 22wt% Al 2 o 3 , 54wt% SiO 2 , 2wt% B 2 o 3 , 2wt% ZrO 2 , 3wt% TiO 2 , 0.16wt% CaO, 0.04wt% K 2 O and 0.21 wt% Na 2 O mix, grind, stir, obtain compound;

[0084] The obtained mixture is placed in a crucible, melted at 1580°C for 4 hours, and the obtained glass melt is poured into a mold to form a basic glass;

[0085] The obtained base glass is subjected to thermal analysis (DTA) to obtain the transition temperature and crystallization temperature of the base glass;

[0086] According to the DTA test results, the obtained base glass was subjected to nucleation treatment at 600° C. for 4 hours and crystallization treatment at 1100° C. for 2 hours to obtain cordierite-based nano-glass ceramics.

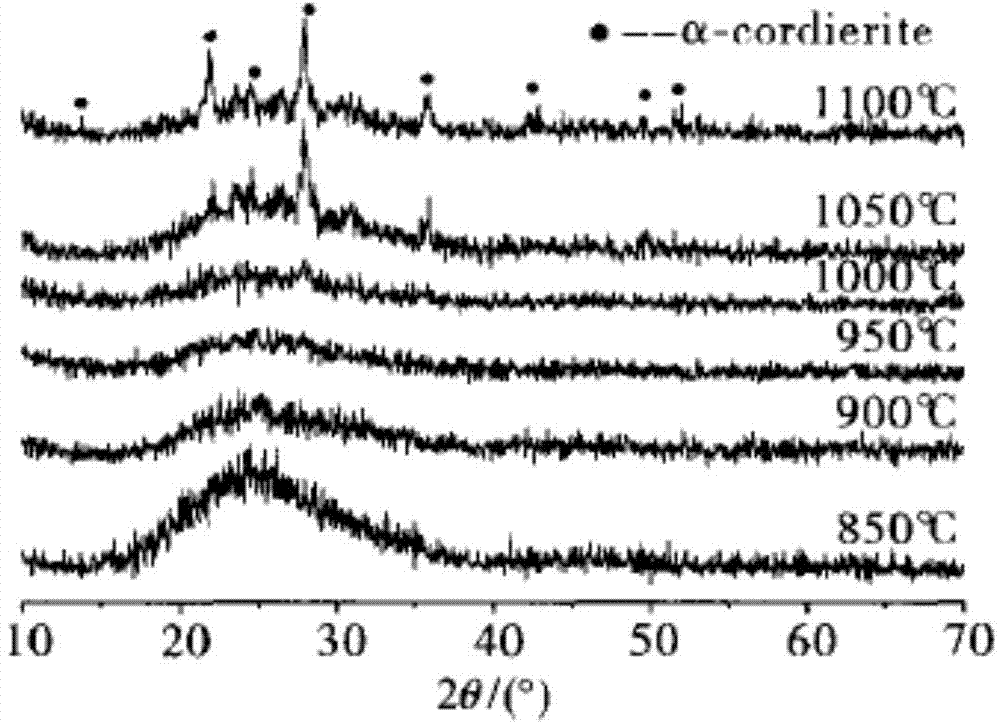

[0087] The present invention carries out X-ray diffraction (XRD) analysis to the obtained cordierite-based nano-glass ceramics, and the results are as follows: figure 2 as shown, figure 2 The XRD spectrum of the cordierite-based nano-glass-ceramic that is...

Embodiment 2

[0091] The cordierite nano glass-ceramic was prepared according to the technical scheme of Example 1, except that the crystallization temperature in this example was 1050°C.

[0092] The present invention carries out XRD analysis to the obtained cordierite nano-based glass-ceramics, the results are as follows figure 2 as shown, figure 2 The XRD spectrum of the cordierite-based nano-glass ceramics obtained in Examples 1 to 2 of the present invention and Comparative Examples 1 to 4 is obtained by figure 2 It can be seen that the crystal phase in the cordierite-based nanoglass-ceramics obtained in this embodiment is α-cordierite;

[0093] The present invention carries out scanning electron microscope (SEM) scanning analysis to the obtained cordierite-based nano glass-ceramics, and the result shows that the size of α-cordierite crystals in the glass-ceramics obtained by the present invention is nanoscale;

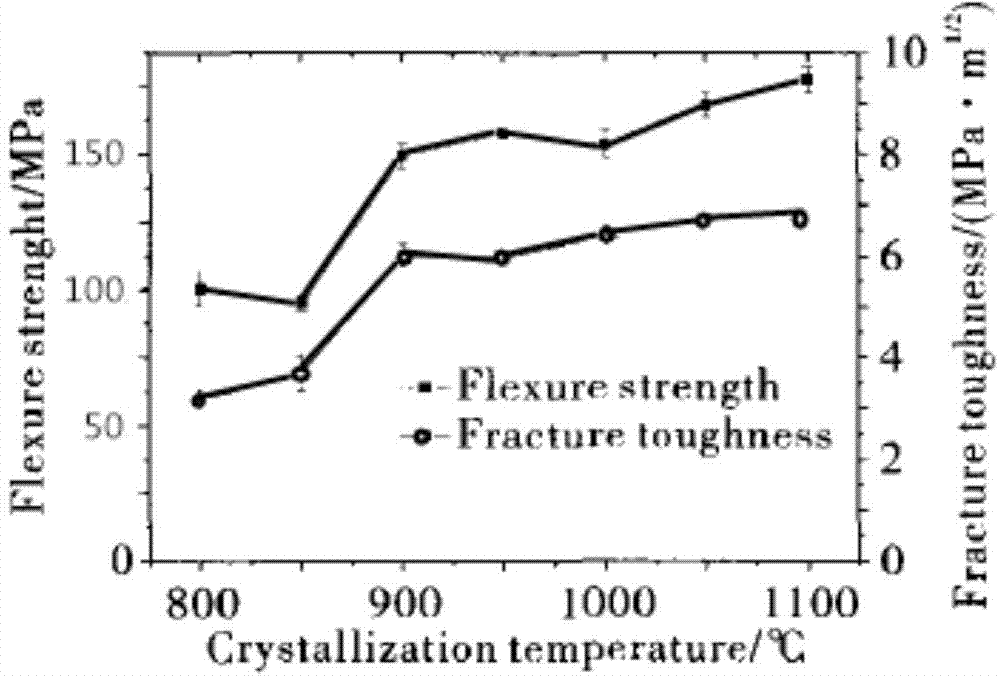

[0094] The mechanical properties of the cordierite-based nano-glass-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com