Crystalline metallic nano-particles and colloids thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

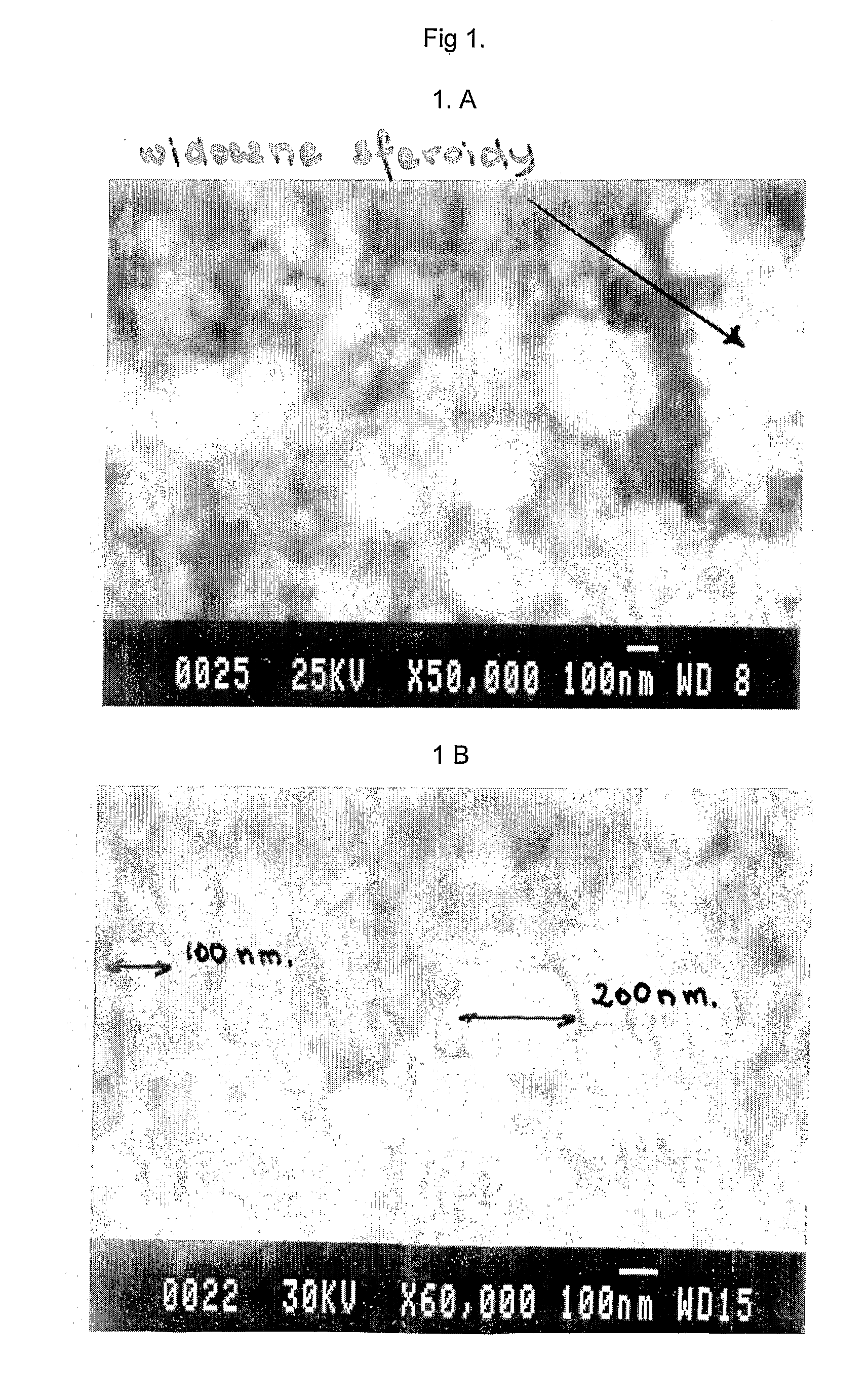

[0039]Longitudinal forces and the explosive degradation of wires: In the literature cited, published in Poland in 2001, it is shown that longitudinal forces occur in every conductor under the electrical current flow. Such forces are strictly quantum mechanical in character. The source of the longitudinal forces in metallic conductors is explained therefore in transfer of electrons which are colliding with the crystalline lattice of the conductor (phonons) as well as with impurities and structural metal crystal defects.

[0040]Conductor explosions as a source of nano-particles: Metallic conductors subjected to the high-density currents “break up into fragments”. This occurs when forces resulting from the collisions with metal ions exceed metal cohesive forces. The degrading metal forms an immense number of microscopic metallic fragments. The technique in which such a degradation takes place in a liquid medium is of particular practical importance. Metallic fragments formed as a result ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com